Text

What is pipe expansion joint and expansion devices| Flexpert bellows

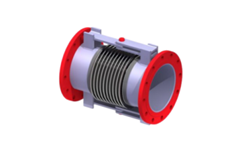

What is pipe expansion joint?

Pipe Expansion Joint is solitary in the vacuum pump from another system to allow the thermal expansion and misalignment in the piping system.

Why would I need one?

· Thermal Expansion of Piping

· Solving the piping misalignment and lateral settlement offsets

· Pump & Equipment vibration

· Shock and bending loads

What are the types of expansion joints?

· Metal bellows

· Fabric joints

· Rubber joints

Metal bellows:

Metal bellows are elastic like a vessel that can be easily be compressed when pressure is applied or extended under a vacuum, making them ideal for absorbing thermal movement and vibration in a piping system that is being transported at high temperatures such as vibration caused due by exhaust gases or steam

Fabric joints:

Fabric joints are an essential component in most industrial plants. It is installed as the flexible connection in duct and piping system to take up or compensate for thermal expansion, vibration, and/or misalignment

Rubber joints:

Rubber Bellows are used in Pump connectors & pipelines. Flexible bellows eliminate the stress in the metallic pipeline and compensate for axial and lateral misalignment.

What are the types of metal expansion joints?

· Single unstrained

· Universal expansion joint

· Single tied expansion joint

· Tied universal expansion joint

· Pressurized balanced expansion joint

· Gimbal expansion joint

· Hinged expansion joint

· Inline pressurized expansion joint

Get to know more about expansion joints & bellows click now

1 note

·

View note

Text

General application of bellows

Bellows:

Flexible bellows are expansion joints; they are the flexible element that absorbs movements in the pipe system. Bellows can be designed to absorb one of these movements or more of these movements in a combination.

General application:

Convolution formed (bellows) is used in industrial applications for piping systems.

1. Load Mechanical Seals ad cells

2. Vacuum interrupters

3. Mechanical Seals

4. Pressure gauges

5. Exhaust pipe Expansion Joint

1. Load Mechanical Seals ad cells:

A bellow has been installed over the strain gauge to protect it from outside damages or weather influences.

2. Vacuum interrupter:

Is it a switch that uses electrical contacts in a vacuum? It is a beneficial component of medium–voltage circuit breakers and high voltage circuit breakers.

3. Mechanical Seals:

It is simply a method of containing fluid with a vessel. The rotating shaft passes through a stationary housing or occasionally where the housing rotates around the shaft.

4. Pressure gauges

It is an instrument for measuring the condition of fluid (liquid or gas) that is approximate by the force that the fluid would exert when resting on a unit area such as pounds per square centimeter.

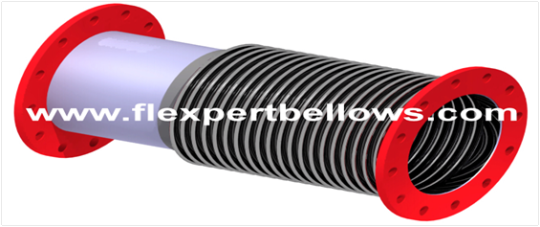

5. Exhaust pipe Expansion Joint :

Exhaust pipe expansion joints are designed to absorb heat induced by expansion joint and contraction of pipe systems and exhaust systems.

To know more about us and the product we manufacture click here now

0 notes

Text

Manufacturer & Exporter of Industrial Bellows metallic bellows, universal bellows, & rectangular bellows – Flexpert Bellows Pvt Ltd in India

Manufacturer & Exporter of Industrial Bellows metallic bellows, universal bellows, & rectangular bel

About us:

• Established in the year 1992

• In house workshop unit

• Team of Experienced Engineers

• High-Quality Designed & Customized Products

Why Us:

• Timely Deliveries

• Competitive Pricing

• Customized Solution

Products

• Industrial Universal Bellows

• Rectangular / Axial Expansion Bellow

• Camera type Rectangular Bellows & Bellows Expansion Joint

• Metallic Bellows & Pressure Bellows

• Industry-Specific Metal Bellow

Industrial Universal Bellows :

• Universal Bellow

• Hinged type universal bellows

• Exhaust Bellows

Rectangular / Axial Expansion Joint

• Rectangular Bellows

• Rectangular type Bellows

• Square Bellows

• Axial Bellows

• Axial Bellows ( Thick Wall )

Camera Type Rectangular Bellows Expansion Joints

• Camera Bellows

• Hinged Bellows

• Piping Bellows

Metallic Bellows & Pressurized Bellows:

• Metal Bellows

• Steel Bellows

• Hot Blast Bellows

• Gimbal Bellows

• Pressurized Balanced Bellows

Industries specific metallic bellows:

• Bellows for cement plants / Industries

• Bellows for Petroleum Industries

• Bellows in chemical industries

• Bellows for agro & Fertilizer industries

• Bellows for shipping industries

• Bellows for Defense

Get Metal Expansion Joint and Expansion Bellows product catalog with the best price and fast delivery.

Click Here Now

0 notes

Text

Flexible Piping system an overview | Piping system in India

What is a flexible pipeline?

A flexible pipe capable of configuring a product made up of several layers. The components are leak-proof thermoplastic barriers and Corrosion-resistant steel wire.

Why is flexible piping used?

Used in applications there are particular requirements to accommodate large relative motions, provide high corrosion resistance, and reduce the time cost of installation.

What are the types of pipes?

· Copper

· Galvanized steel

· PVC (polyvinyl chloride)

· Cross-linked polyethylene

What is the process of pipe?

The pipe is to transport (air, steam, water, industrial gases, and fuels, chemical) around an industrial facility.

What are the benefits of using a flexible piping system?

· Easy to install

· Resistant to chemical

· Leakproof

· Works on High pressure

What is the disadvantage of a pipeline?

· It is not so flexible and can be used only for a few fixed points

· Its capacity cannot be increased once fixed

· It is hard to make security arrangements for pipelines

How often flexible hoses should be replaced?

Replaced every five years. It's a good idea to check them regularly for corrosion or rust spots on the braided section of pipes.

What are the main characteristics of flexible pipes?

The main characteristics of flexible pipe:

· Flexibility

Instability

· Modularity

· Corrosion

· Resistance

· Reusability

1. Flexibility:

Flexibility piping measures the reaction loads and stresses resulting from gravity, internal and external pressure, temperature fluctuation, and flow-induced loads.

2. Installability:

The flexible pipe is available in a steady length, laying the speed is usually around 500 meters per hour. The removal of interfaces decreases operational risk.

3. Modularity:

Modularity design is a design principle that subdivides a system into smaller parts called modules (such as modular process skids)

4. High-Pressure Resistance:

High pressure and High temperature are designed to operate the pressure that passes through pipelines the high-pressure gases were transported through pressure piping.

5. Reusability:

It is capable to use again or repeatedly. Flexible pipe resists all fluid pressure currently encountered in most subsea applications.

To know more about flexible piping system

Click here now

0 notes

Text

Manufacturing of Piping system | Metallic Expansion Joint in India

What is Expansion Joint?

It is a flexible component used in the piping system to absorb the expansion, contraction, deflection, or bending in torsion in a piping system. The bellows are used at the piping connection to the equipment nozzle (Pump, compressor, turbines) to absorb deflection in the piping system caused by thermal expansion or contraction of pipelines.

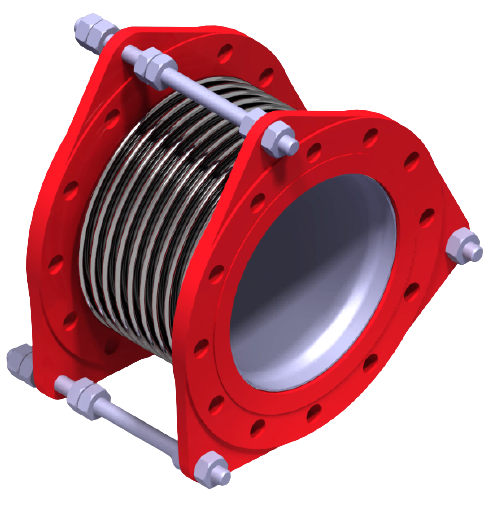

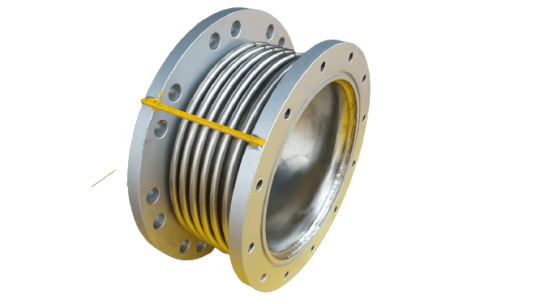

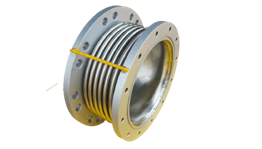

What is a Metallic Expansion Joint?

Metal Expansion Joints are compensators that are compensating elements for thermal expansion and relative movements in the pipeline and containers and machine. It consists of one or more metal bellow connectors both ends and ties rods on the application.

What is a metal expansion joint used?

Metal expansion joints used in applications where thermal expansion is an issue. The temperature increases in the pipe compress to compensate for the movements taking the stress of the anchor and pipes.

Advantages of metal expansion joint:

Weight reduction

Cost reduction

Reduce engineering

Better flexibility for piping layout

What is a piping system?

A piping system is a network of pipes fitting valves intended to perform a specific job to carry or transfer from one equipment to another. Steam piping into manufacturing plant, oil piping in refinery and so on.

Application of piping system sector-wise:

Petrochemical refinery market

Chemical processing

Special product application

Pulp and paper

OEM engine

Measurement and control system

What are the four important piping systems?

Piping systems for gas and water distribution, sewer, and drainage system, cable protection, communication, and industrial installations constitute the long durability of various industries and communities.

Advantages of the piping system:

Lightweight

Flexibility

Watertight joints

Safe material

Long lengths

Longer lengths

Get Metal Expansion Joint and Expansion Bellows catalog with the best price and fast delivery.

Click Here Now

0 notes

Text

Get to know more about Pipe Expansion Joint in India

What is piping Expansion Joint?

A rubber expansion joint pipe is a flexible connector of two pipes. It provides stress relief in a piping system due to thermal and mechanical vibration or movements. … Retaining Ring – Used to compress the expansion joint flange to the mating flange to create a seal. Also called as clamp bars or backing bars.

Expansion Joint Piping

What is the use of Expansion Joint Piping?

Piping Expansion Joint or Expansion Bellows are highly engineered and mechanical devices containing more than one metal/ rubber bellows. Expansion Joints use to absorb dimensional changes that are caused by thermal expansion or contraction of the pipeline, duct, or vessel or while containing the system pressure

What are the benefits of Expansion piping?

· Simple in design and function

· Space Reduction

· Weight Reduction

· Cost Reduction

· Better Flexibility of piping Layout

· Reliable and proven in the field

#Expansionjoint#metalexpansionjoint#Expansionbellows#Bellows#pipingsystem#expansionpiping#rubberbellows#catalogue

0 notes

Text

Introduction to Expansion Joint (Bellows) in India

Overview of Expansion Joint:

An expansion joint or bellows is a flexible component. It is used in the piping system to absorb the expansion, contraction, deflection, or bending torsion in a piping system. An expansion joint or bellows is used in piping connection to the equipment nozzle (Pump, compressor, turbines) to absorb deflection in the piping system caused by thermal expansion or contraction of the pipelines, Bellows absorb the piping movements and safeguard the connected tools from the Transmission of excessive loads to the equipment nozzle from the joint piping system. An Expansion Joints is installed in the piping system and duct systems can serve the following purpose:

Compensate thermal and expansion joint

Reduce noise and vibration

Isolate vibration through a connected system

Compensate misalignment

Compensate thermal and expansion joint

Hinged Expansion Joint:

Hinged Expansion Joints absorb angular movement when it occurs in only one plane called Angular Expansion Joints or Hinged Bellows.

Gimbal Expansion Joint:

Gimbal Expansion Joints absorb angular rotation in any plane, using two pairs of hinges attached to a floating gimbals ring.

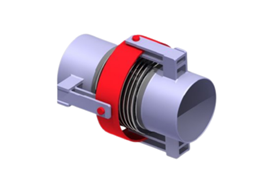

Universal Expansion Joint:

The Universal Expansion Joints consist of two bellows elements joined jointly by a spool piece called Double Bellows Expansion Joint or Universal Bellows. The Universal Expansion Joint is used where more lateral movement is to be absorbed It is beyond the capacity of a single Axial Expansion Joint and when there is a limitation on the number of lateral forces allowed by the connecting pipe system.

Pressure Balanced Expansion Joint:

In-line pressure balanced expansion joints are designed to absorb externally imposed axial movement without imposing the pressure loading on the system. It is accomplished by using two bellows pair at line pressure tied together and acting in opposite directions. The pressure loading on the piping or equipment is not acceptable.

Get the Latest Metal Expansion Joint and Expansion Bellows catalog with the best price and fast delivery any were in the world.

Click Here Now

1 note

·

View note

Text

Pipe Expansion Joint for pressure and vacuum| Flexpert Bellows Pvt Ltd

Expansion Joint

Pipe Expansion Joint is isolated in the vacuum pump from another system to allow the thermal expansion and misalignment in the piping system. The Rubber expansion joint features a single or double-arched bellow constructed for the molded elastomeric.

The function of Expansion Joints

· Reduce pressure thrust and load

· Reduce sound transmitted in the pipeline system

· Directional movement

· Compensate misalignment

They typically come in three different applications:

· Metal

· Rubber

· Braided

Metal:

Metal Expansion Joints are compensating elements of thermal and relative movements in the pipelines and compensator. It consists of more than one metal bellows connector at both ends.

Rubber:

Rubber Bellows are used in Pumps and pipelines. Bellows eliminate the stress and pressure in the metallic pipeline and compensate axial and lateral misalignment. The Vibration stops the hammering effect in the piping system.

Braided:

Braided stainless hoses are with metal liners aren’t technical expansion joints, more of the flexible connector. They work in high pressure and temperature application requiring vibration damping or misalignment. The Braids provide lateral and angular movement.

Get the Latest Metal Expansion Joint and Expansion Bellows catalog with the best price and fast delivery any were in the world.

Click Here Now

1 note

·

View note

Text

What are the Metal Expansion Joint and types of expansion joints?

What is Metal Expansion Joint?

Metal Expansion joints (compensators) are compensating elements of thermal and relative movements in the pipelines and compensator. It consists of more than one metal bellows connector at both ends. An Expansion Joints used in various sectors production, paper industry, chemical industry, water treatment oil, gas. Pipeline occurs in thermal movement vibration then can expansion joints be used.

What are the types of metal expansion joints?

Single unstrained

Universal Expansion Joints

Single tied Expansion Joints

Tied Universal Expansion Joint

Gimbal Expansion Joint

Hinged Expansion Joint

Single Unstrained:

This Expansion Joints come with one Bellow and end section. This type of Expansion Joint requires most control of adjacent piping to anchor and guide.

Universal Expansion Joints

Universal Expansion Joints have tie rods that eliminate pressure thrust from the pipe system and limit movement.

Single Untied Expansion Joint

This type of bellows as one set of convolution

Very low-pressure piping system

Axial pressure thrust will be less and transmitted to the piping system

Tied Universal Expansion Joint

It is exactly like the universal expansion joint but the tie rods have been designed into units.

Gimbal Expansion Joint

A Gimbal Expansion Joint designed to permit angular rotation in any plane of 2 Pair of hinges affixed to common floating gimbals ring

Hinged Expansion Joint

The hinged Expansion joint contains one bellows and is designed to permit angular rotation in one plane only the use of a pair of pins running through the plates attached to the expansion joints end.

Get the Latest Metal Expansion Joint and Expansion Bellows catalog with the best price and fast delivery any were in the world.

Click Here Now

0 notes

Text

Manufacturing Rubber Bellows Expansion Joints in India

Rubber Bellows are used in Pumps & pipelines. Flexible bellows eliminate the stress in the metallic pipeline and compensate axial and lateral misalignment. It should absorb the vibration and stop the hammering effect in the piping system.

What is the function of expansion below?

Expansion Bellows are used to absorb in thermal expansion. They can also be used in cryogenic lines and reduce vibration in the piping system. A bellows functions by compressing or extending according to the axial motion required in the piping. There are wide range of metallic bellows design variety of material.

Is Expansion Joint necessary?

Expansion Joints are necessary in the piping system that convey high temperature substances such as steam or exhaust gases, or to absorb the movement and vibration.

How does bellows work?

Metal bellows are elastic vessel that can be compressed, when the pressure is applied to the outside of the buzzle. It is applied to the outside of vessel or extends under vacuum.

#rubberbellows#bellows#expansionjoint#expansionbellows#exhaustgases#metalbellows#pipeexpansionjoint#pipeexpansionjoints#expansionjointpipes#expansionjointpipe

0 notes

Text

Why should an Expansion joint be inserted in the Piping system?

Why should an expansion joint be inserted into the piping system?

Expansion Joints are installed in the piping system to absorb vibration and shock. They also have the Advantages of reducing noise and compensating caused by misalignment.

What are expansion joints and why they are necessary?

An Expansion Joint ( Bellows )or movement joint is an assembly designed to hold the parts together while absorbing the temperature-induced expansion and construction of building material and vibration or to allow the movement due to ground settlement.

What is the material used for Expansion Joints?

Expansion Joints are in Metallic and Non- Metallic materials. The expansion joints used in the piping industry are; stainless steel (Austenitic steel, SS 304 SS 316) High grade nickel alloy steel (Inconel, Incoloy, Monel, and Hastelloy)

What are the Advantages of Expansion Joints?

· Expansion joints helps in reducing noise, vibration, and shock

· Expansion Joints are installed in the piping system to absorb vibration and shock.

· Expansion Joints permits thermal and expansion without inducing the stress in elements

· Better flexibility for Piping Layout

0 notes

Text

What is the need for bellows expansion joint in a piping system?

What is the need for bellows expansion joint in a piping system?

An expansion joint pipe is a flexible component that is inserted into the pipelines to safely absorb the dimensional changes of steel piping systems and ducts.

What is Expansion Joint?

• other terms are used for expansion joints as expansion bellows, flexible joints, and compensator.

• An Expansion Joint is compressed by one or more metal bellows (stainless steel) or from

material like rubber or fabric

• Metal bellows are suitable in all the high temperatures; metal bellows have high strength properties and are resistant to corrosion

• The Metal bellows are implemented in such a way to absorb one of these movements or to absorb more of the movement combination

• The use of Expansion Joints will always prove to be the simplest and most effective method of compensating for thermal expansion and contraction.

Metal Bellows Expansion Joint

What is the need for an expansion joint in the piping system?

• Expansion Joints bellows are used to absorb vibration and shock in the piping system.

• This also has the advantage of reducing the noise and compensating caused by misalignment.

What is a pipe expansion joint and why do we need it?

• Piping Expansion Joints or Expansion bellows are highly engineered mechanical devices containing one or more metal /rubber bellows.

• Expansion Joints are used to absorb the dimensional changes caused by the thermal expansion or contraction of a pipeline duct, vessel while containing the system pressure

• Expansion Joints are successfully used in the refiner’s .chemical and petrochemical plants,

the nuclear power plant, automotive and aerospace heating and cooling system.

Why Install pipe Expansion Joint

• To absorb the movement of thermal expansion as well compression

• To relieve the system stress and strain

• To reduce the noise and vibration

• To compensate for misalignment

What are the components of expansion joints?

Bellows

Tie rods

Flanges

Shipping bar

Protective cover and internal liners

What are bellows?

Bellows are the most important part of the expansion piping joints.

There are two types

• Formed Bellows

• Fabricated Bellows

0 notes

Text

What is Expansion Piping Joint?

What is Expansion Piping?

Expansion Piping expands and contracts as a result of temperature change. As the temperature

increases the pipes expand. When the temperature decreases, pipes compact. For example, if a pipe is in a fire protection system restrained at both ends, stress will begin to build, and the Pipe Expand

Where are expansion joints in use?

Steel expansion joints components in many industries and are used extensively in among

others:

· In the Energy sector (power plants, nuclear power plants, district heating pipe systems, etc.)

· Steel plants

· Petrochemical industry

· Chemical industries

· Process industry

· Exhaust systems and engines

· Pulp and paper industries

· LNG/LPG tankers, -carriers, etc.

Why is an Expansion Pipe used?

Expansion joints are installed in a piping system to control the vibration and shock.

They also have advantages such as reducing the noise and compensating caused by misalignment.

Expansion joints can be sketched for thermal expansion in hot applications.

Why is an expansion pipe needed?

It provides sufficient flexibility to prevent the thermal expansion and contraction from causing

excessive stresses in the Piping System.

Expansion Loops are often required in high-temperature gases

What are the applications for Expansion Piping?

Pipe Expansion Joints are the systems that convey High-Temperature commodities such as steam or exhaust gases or absorb movement and vibration, Expansion Joint is a useful component in an infinite number of applications

What are the advantages of Expansion Piping?

Simple in design and function

Space reduction

Weight Reduction

Cost Reduction

Better flexibility for piping layout

Reliable and proven in this field

0 notes

Text

Manufacturing Metallic bellows from India

What are metallic bellows?

The main element of the expansion joint, which consists of one or more convolutions, is bellows. The performance of the bellow depends on the geometric bellows. Hence the type of raw material and its properties, geometric features, other influencing designing factors, construction or manufacturing method, and performance testing bellows are necessary to study.

Bellows

What are the types of bellows?

Formed Bellows

These types of Expansion Joint used in the low-pressure system they are cost-effective and can be a substitute system

Fabricated Bellows are of various shape polygons, rectangular, etc.

Fabricated Bellows

Formed from a thin wall tube, formed bellows contains only longitudinal welds, and exhibits significant flexibility

Formed Bellows of varying shapes are made from single or multiply plies of suitable material (usually stainless steel) ranging in thickness from .004" to .125" and greater, and in diameter of 3/4 to over 12 ft

0 notes

Text

Manufacturing Expansion Joints and Bellows in India

What is Expansion Joint?

An Expansion Joint is a device containing one or more metal bellows used to absorb the dimensional changes such as those caused by the thermal expansion or contraction of a pipeline, duct, or vessel

What is the use of Expansion joints and bellows?

Expansion Joints and Bellows are used in the Piping System.

They are made of add like flow liners, covers, and tie rods. The metal bellows act like springs but they are restricted to contain the pressure of the fluid that flows through the expansion joint.

A proper flow depends much on the movement of the connected piping.

If Expansion Joints are removed from the piping system, high stress would be created by the thermal expansion.

This can cause massive pressure resulting in the cracks of the welds and bending of the pipes.

The corrugations are designed in such a way that they can tolerate the massive pressure of the entire system.

The assembly of the bellows is placed in such a way that it can flux under the thermal movement of the connected piping.

What are the types of expansion joints?

Expansion Joint

Types

Axial Expansion Joint

Lateral Expansion Joint

Hinged Expansion Joint

Universal Bellows Expansion Joint

Gimbal Expansion Joint

Inline Pressurized Expansion Joint

Elbow Pressurized Expansion Joint

Externally Pressurized Expansion Joint

Pump Connectors

Exhaust Bellows Expansion Joint

Rectangular Expansion Joint

Heavy Wall Expansion Joint

Bellows type Dismantling Joints

Bellows Element for Expansion Joints

To know more click on the above Expansion Joints to get a complete overview.

How do Expansion joints work?

An Expansion Joint or movement joint is an assembly designed to hold the parts together while safely absorbing the temperature-induced expansion and contraction of building materials, and vibration, or to allow the movement due to ground settlement.

0 notes

Text

Get to know more about Pipe Expansion Joint

What is piping Expansion Joint?

A rubber expansion joint pipe is a flexible connector of two pipes. It provides stress relief in a piping system due to thermal and mechanical vibration or movements. … Retaining Ring — Used to compress the expansion joint flange to the mating flange to create a seal. Also called clamp bars or backing bars.

What is the use of Expansion Joint Piping?

Piping Expansion Joint or Expansion Bellows are highly engineered and mechanical device containing one or more metal/ rubber bellows. Expansion Joints are used to absorb dimensional changes that is caused by thermal expansion or contraction of pipeline, duct or vessel or while containing the system pressure

What are the benefits of Expansion piping?

Simple in design and function

Space Reduction

Weight Reduction

Cost Reduction

Better Flexibility of piping Layout

Reliable and proven in the field

0 notes

Text

Expansion Joint pipe – Flexpert bellows Pvt Ltd

Expansion Joint pipe — Flexpert bellows Pvt Ltd

What is Expansion joint pipe?

A rubber pipe expansion joint is a flexible connector of two pipes. That provides a stress relief in a piping system due to the thermal and mechanical vibration or movements….Retaining the Ring — Use to compress the expansion joint flange to the mating flange to create a seal. Are also called as backing bars

Where Expansion joint pipe used?

The Expansion joints are used in the piping systems to absorb the thermal expansion or terminal movement where the use of expansion loops is impractical. Expansion joints are available in a wide range of shapes and material. Bellows you will find a short description of metallic, Rubber and so on.

What is the advantage of expansion joint pipe?

Reliable and proven in the field of expansion joint pipe

Simple design function

Cost Reduction

Weight Reduction

Better Flexibility in expansion joint pipe

What are the features of expansion joint pipe?

Expansion Joints are also called as bellows. Expansion Joints are used to absorb the contraction in cryogenic and to reduce the vibration in piping systems. The Materials of construction for the bellows that can be stainless steel or rubber or even a composite material

0 notes