Text

Perhaps your product connections need welding bolts!

Stud welding refers to one end of the stud and the workpiece to be welded (plates or fittings). Surface contact between the two produces an electric arc, to be melted when the joint surface quickly moves to the stud to exert a certain pressure, squeezes together to form a weld, and creates a solid connection of the process method.

The stud welding process is fast and reliable, simplified, easy to operate, reduces costs, and has many other advantages. The current role of the stud in the cabin is to fix the wiring harness, interior parts, and carpets; the role of the stud outside the cabin is to improve the wiring harness, fuel lines, brake fluid lines, heat insulation panels, deflector panels, and other chassis accessories.

Bump welding involves pre-processing one or more bumps on the joint surface of the welded parts so that they are in contact with the surface of another welded part, pressurized and electrically heated; the bumps collapse so that these contact points form a welded joint of the resistance welding method.

1. Model: standard parts with different diameter requirements, energy storage type stud welding is generally used for welding diameter of 3-10 mm stud, arc stud welding, weldable stud diameter range of 3-25 mm, convex welding standard parts models are generally between M4 and M12, and because of purchasing problems, too small may not be applied in the actual process.

2. Material: convex welding is mainly used in the bottom of solid steel and high-strength steel; hot-forming steel is also used, but the aluminum parts can not convex welding, pulling the arc stud welding on the welding base material requirements welding base material surface can conduct electricity, even if the surface of the fused surface has a slight corrosion, oil, metal plating, and other impurities also does not affect the welding, storage type stud welding on the base material requirements are stringent, the surface of the base material is terrible will lead to increased resistance, can not be welded live welded! If the plating layer is thicker, it will be challenging to solder.

3. Appearance: energy storage type stud welding around the surface of the plate without evident traces of damage; the back of the plate, no noticeable marks; the front of the arc stud welding black around the weld, can not be erased; the back of a certain degree of deformation, stud welding around there will be a certain degree of fusion traces, convex fusing after welding the surrounding area does not have to push the accumulation, and the surrounding will not blacken, in addition to the end of the convex welding, the convex welding process of the other sheet metal needs to be opened up, the process of stud welding does not need to be opened up. The stud welding process does not require holes to be made.

IFI 148 (UC4) - 2002 UC4 Type UC4 Projection Weld Studs

Size: M10X50mm

Strength Grade:8.8,10.9 Class

Suppose you are looking for high-quality Weld screws for metal and fasteners or technical support for structural design, welcome to contact me. Thanks.Email:[email protected]

Website: https://www.juxinfasteners.com

0 notes

Text

New Energy Electric Vehicle PACK Pack Fastener Industry Solutions

What is Battery PACK? How to choose suppliers for Battery PACK Long Screw and Battery PACK Long Bolt?

Battery PACK generally refers to packaging, encapsulation, and assembly; battery PACK generally refers to a combination of batteries because lithium batteries are composed of a specific voltage and capacity through the series and parallel connection of a single lithium battery, plus the protection plate, can be charged and discharged assembly process. Or two batteries in series, according to customer requirements, to form a particular shape; we call it PACK. New energy electric vehicles are revolutionizing our current and future travel modes. Ju Xin Fasteners fastening system, for the new electric vehicle industry from the battery PACK program in the parts fasteners, to help customers make the right decision from the beginning so that the battery PACK products now and in the future. PACK products are competitive now and in the future. Please get in touch with us if you want high-quality strength 10.9-grade carbon steel hexagon flange bolts or technical support for structural design.

Hanks.Email:[email protected].

0 notes

Text

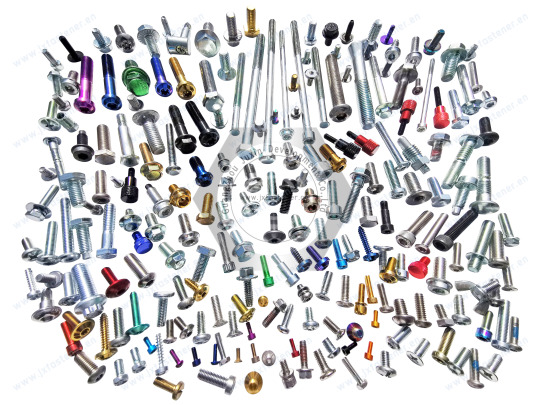

Lithium's new energy vehicle industry, screws, and nuts have the characteristics and functional solutions.

Screws and nuts are essential connecting elements in the lithium battery industry. They are widely used in lithium battery production equipment and related assembly and installation processes. In the lithium industry, screws, as necessary mechanical connectors, play a vital role in the performance and reliability of the equipment. As the heart of a pure electric vehicle, the power battery directly determines the car's safety, life, and performance. The power battery is a lithium battery; its temperature, sealing, and safety protection requirements are incredibly high, and screws in the assembly process play an indispensable role. High-quality materials and advanced manufacturing processes are used to produce the screws to ensure the high precision, quality, and durability of each screw. Screws can be supplied in a variety of different materials, sizes, and specifications, such as stainless steel, carbon steel, aluminum alloy, etc., according to demand. Our product range includes a variety of standard screws, self-tapping screws, check screws, rebound screws, cylindrical head screws, and more. Mild steel is suitable for manufacturing hardware parts, such as shafts, gears, flanges, brackets, etc. Meanwhile, it is also widely used in the new energy field, commonly used in battery boxes, charging piles, wind turbines, hub motors, drive motors, and other hardware parts.

I've included more details; please see the link below.

#Lithium's new energy vehicle industry#screws#and nuts have the characteristics and functional solutions.

0 notes

Text

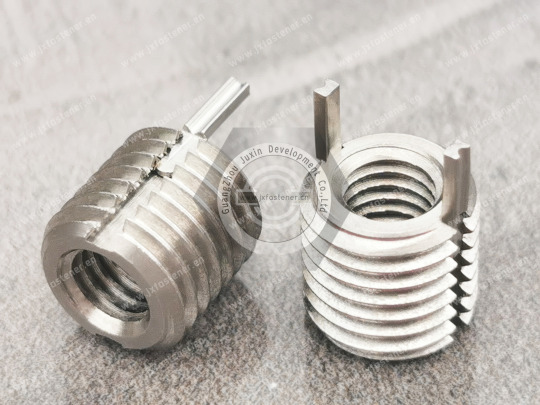

Stainless Steel Helical Inserts are a new type of internal thread fastener, which is wound by high strength, high precision, and high surface quality corrosion-resistant diamond-shaped Stainless Steel Helical Inserts, shaped like a spring. The Stainless Steel Helical Inserts set is inserted into the screw hole, the outer surface of the wire screw set is attached to the screw hole by the elastic force, and the inner surface forms a new thread, which is used to screw in the screw or bolt, so that the screw or bolt is not directly in contact with the matrix, protecting the matrix and screw. It can prolong the service life of the thread, increase the strength of the thread connection, increase the force surface of the thread, increase the bearing capacity and fatigue strength of the thread connection, and anti-seismic and anti-loosening. The application of low-strength engineering materials such as aluminum and magnesium alloy can improve the strength and wear resistance of thread, and the Stainless Steel Helical Inserts can also improve the force of thread, make the overall force of thread, and improve the strength of thread connection. Stainless Steel Helical Inserts can also be used to repair worn or damaged internal threaded holes. Stainless Steel Helical Inserts and self-tapping screw sleeve products, in aviation, spacecraft, Marine, automotive power machinery, hydraulic transmission machinery, pneumatic tools, pneumatic components, chemical fiber, textile, tobacco machinery, optical instruments, electrical appliances, high-voltage switches, automotive repair and other industries of products and equipment have been widely used. If you are looking for high-quality steel helical inserts and fasteners or technical support for structural design, welcome to contact me. Thanks.Email:[email protected]

0 notes

Text

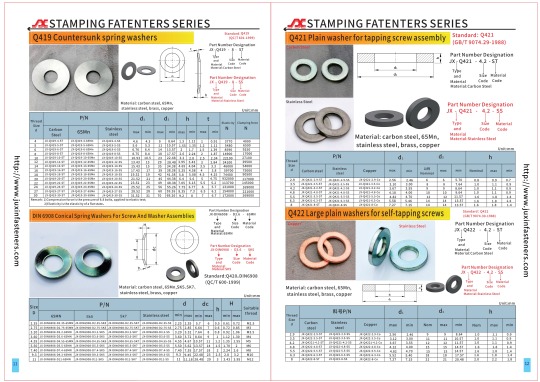

The use of washers: Washers are placed between nuts or bolts, screws, and the surface of the connected parts to protect the surface of the connected parts from being scratched by the thread, increase the contact area between the connected parts and the nut, and reduce the pressure per unit area acting on the surface of the connected parts. Performance level 100HV washers for performance level ≤ 6 C nuts, performance level ≤ 6.8 bolts, screws, surface hardening of the self-extruding screws; performance level 200HV washers for performance level ≤ 8 A, B nuts, performance level ≤ 8.8 A, B bolts, screws, stainless steel and similar chemical composition bolts, screws, nuts, surface hardening of the self-extruding screws; performance level 300HV washers for performance level ≤ 8 A, B nuts, performance level ≤ 8.8 A, B bolts, screws, nuts, surface hardening of the self-extruding screws. Screws; performance grade 300HV washers for performance grade ≤ 10 A, B grade nuts, performance grade ≤ 10.9 A, B grade bolts, screws.

The function of the washer: The washer is a kind of contour that is circular and nested in the bolt, nut, or other connectors between the mechanical parts. Typically, washers function in the following ways:

1. The washer can increase the pressure between the connecting parts, to ensure that the connecting parts are strong and stable.

2. Washers distribute the load and reduce wear and fatigue between the connecting parts.

3. Washers can fill the gaps between the connectors to prevent loosening and oil leakage.

4. Washers can play a role in isolating moisture and preventing corrosion.

If you are looking for high-quality automotive fastener screws & all kinds of plastic fasteners or technical support for structural design, please contact me. Use our new Product Finder tool, download our Product Catalog, and let us help you get custom [email protected]. Thanks. Website: www.juxinfasteners.com

0 notes

Text

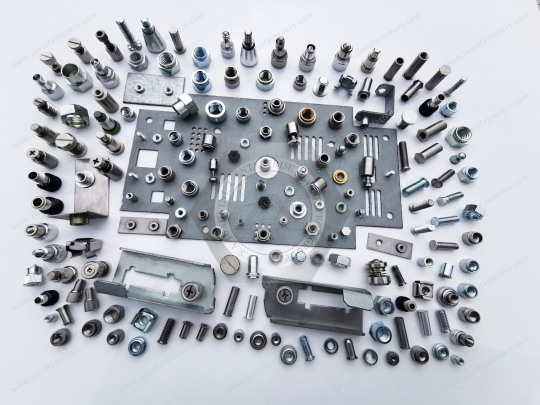

Fasteners are the main components to realize the installation and assembly of automotive parts, and the application study of fasteners in sheet metal connection can further understand the way of automotive design connection.

Through the analysis of automotive sheet metal connection requirements, Different types of fasteners for application research and example analysis. Factors of automobile lightweight, the current automobile uses a large number of high-strength steel plates, and certain designs also use aluminum alloy plates to further reduce the weight of the entire vehicle. Therefore, sheet metal connection in automobile production and assembly occupies a large proportion, such as the welding of automobile body-in-white, the connection of body parts, and the installation of body interior parts, etc. The use of fasteners to connect sheet metal is the main connection method in automobile production other than welding. Due to the variety and huge number of fasteners for automobiles, it is necessary to study the application of fasteners in automobile sheet metal connections.

The fastener types should be selected first in the connection design, and the specific specifications and parameters should be selected after calculation and proofreading. Starting from analyzing the types and characteristics of automotive sheet metal, according to the connection structure and requirements applicable to different fasteners, and by comparing and analyzing the fasteners mainly used in the current automotive industry, the study on the selection of fastener types in sheet metal connection will help to improve the level of automotive development and design.

If you are looking for high-quality fastener screws & all kinds of No-Slip Clip-On Barrel Nuts or technical support for structural design, please contact [email protected]. Thanks. Please Check out our latest post.Website:https://www.juxinfasteners.com/industry-news/research-on-the-application-of-fasteners-in-automotive-sheet-metal-joining.html

0 notes

Text

Spring washers in machinery manufacturing and design have a wide range of applications, such as in automobiles, aircraft, trains, ships, construction machinery, agricultural implements, tool manufacturing, and other fields. In these areas, spring washers are often used for fastener connection, sealing, vibration damping, and damping. Here are a few specific applications.

1. Automobiles and motorcycles:Spring washers have a wide range of applications in automotive and motorcycle production, such as in tires and suspension systems, brake systems, engines, and transmissions. In these applications, spring washers are usually used to improve the fastening force of fasteners, vibration damping, and waterproof and dustproof.

2. Aircraft and marine:Spring washers also have important applications in aircraft and marine production, such as in engines, propellers, hydraulic systems, suspension systems, anchor chains, and ropes. In these applications, spring washers are usually used for vibration damping, sealing, and fastening.

3. Construction Machinery: Construction machinery is used in a variety of engineering projects in mechanical equipment, including excavators, loaders, bulldozers, road rollers, and so on. In this mechanical equipment, spring washers also have a wide range of applications, such as in the hydraulic system, steering system, transmission system, and so on. The application of spring washers can improve the reliability and performance of mechanical equipment. Spring washers are important mechanical seals and elastic components, in the field of mechanical manufacturing and design and have a wide range of applications.www.juxinfasteners.com

0 notes

Text

What is a washer: washers are used in bolts, screws or nuts, etc., the support surface and is connected between the fasteners, can play a role in protecting the surface of the connecting parts, to prevent the fasteners from loosening role of other special purposes. According to its specific role to points, can be divided into flat washers, spring washers, lock washers, and special purpose washers such as sealing washers. Washers are what we often call ordinary washers, the most commonly used, most of the bolts or screws connected to the basic use of flat washers. Flat washers can improve the force condition of the connected parts, to protect the surface state of the connected parts, that is, to increase the contact area, reduce friction and pressure, to protect the screws and nuts. Flat washers are mostly round, there are other shapes such as square washers according to the assembly needs. Specific flat washers - C level, large washers - A and C level, oversized washers - C level, small washers - A level, flat washers - A level, flat washers - chamfered type - A level, square washers, and so on.

If you are looking for high-quality fastener screws & all kinds of washers or technical support for structural design, please contact me.Thanks.Email:[email protected],

MyWhatsApp:+86-13660079809, Website:www.juxinfasteners.com

Facebook/ INS:[email protected]

0 notes

Text

Spring washers are commonly used seals with a variety of different roles, such as improving the fastening force of fasteners, adjusting the fastening force, cushioning vibration and shock, and so on. This article will introduce the role and principle of spring washers.

The role of spring washers: to improve the fastening force of fasteners, when the fastening screw or nut and the workpiece contact, due to the contact surface between the existence of small unevenness, when the torque is applied to the screw or nut, there will be a certain degree of elastic deformation, so that the contact pressure increases. However, when the torque exceeds a certain level, sliding will occur, due to the reduction of sliding friction, the contact pressure will also be reduced. The addition of spring washers can increase the elastic deformation of the fastener, and pre-tighten the spring washers beforehand so that before the fastener begins to slide, the spring washers have begun to play a role in improving the fastening force of the fastener. The ability of spring washers to increase the fastening force of fasteners is one of the most common applications for spring washers.

The material of the spring washer is a key factor in performance and longevity, and the appropriate material needs to be selected based on working conditions and usage requirements. Typically, common materials for spring washers include carbon steel, stainless steel, copper, aluminum, and titanium.

1. Spring washers have a wide range of applications in automotive and motorcycle production, such as in tires and suspension systems, brake systems, engines, and transmissions. In these applications, spring washers are usually used to improve the fastening force of fasteners, vibration and shock absorption, and water and dust resistance.

2. Spring washers also have important applications in aircraft and ship production, such as in engines, propellers, hydraulic systems, suspension systems, anchor chains, and ropes. In these applications, spring washers are usually used for vibration damping, sealing, and fastening.

If you are looking for high-quality fastener screws &all kinds of washers or technical support for structural design, please contact me. Thanks. Email: [email protected],

MyWhatsApp:+86-13660079809, Website:www.juxinfasteners.com

Facebook/ INS:[email protected]

0 notes

Text

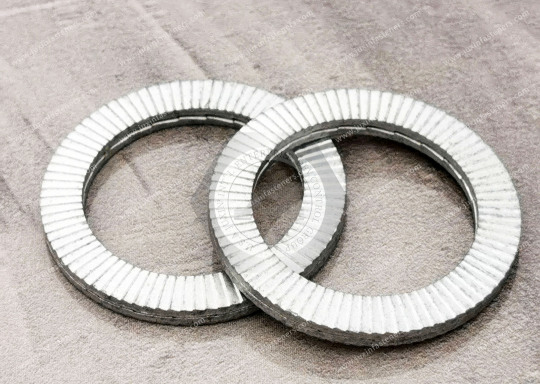

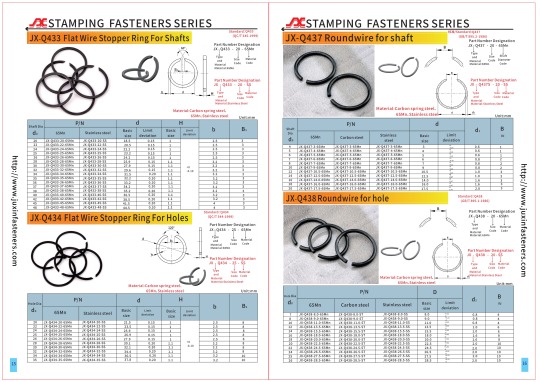

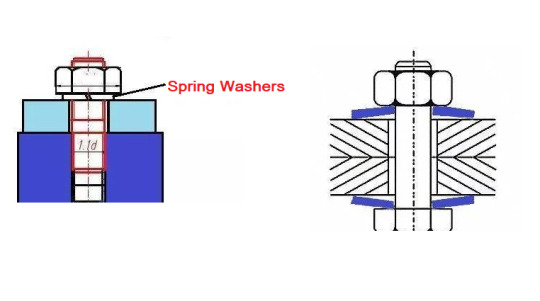

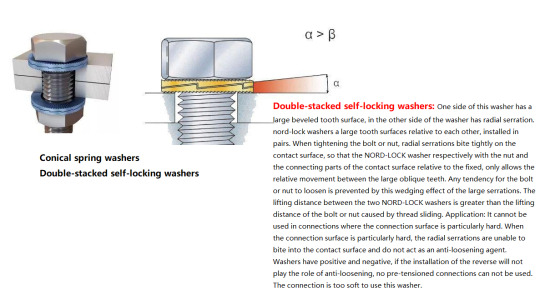

Spring Washers Anti-Loosening Principle, Conical Spring Washers, Double Stacked Self-Locking Washers Industrial Application Solutions

1. Spring washer anti-loosening: spring washer anti-loosening principle is in the spring washer flattened, the spring washer will produce a continuous elastic force so that the inner threads of the nut and the bolt between the external threads produce contact pressure, This pressure produces friction resistance moment, thus preventing the nut from loosening. At the same time, the edges of the openings of the spring washers are embedded in the surface of the nut and the connected part respectively, thus preventing the nut from rotating relative to the connected part. Use: can not be used in the connection of particularly hard connection, If the connection is harder than the washer, the edge of the washer can not be embedded in the surface of the connection, can not play a role in preventing the loosening, also can not be used for high preload requirements of the connection, which will cause the loss of preload accelerated.

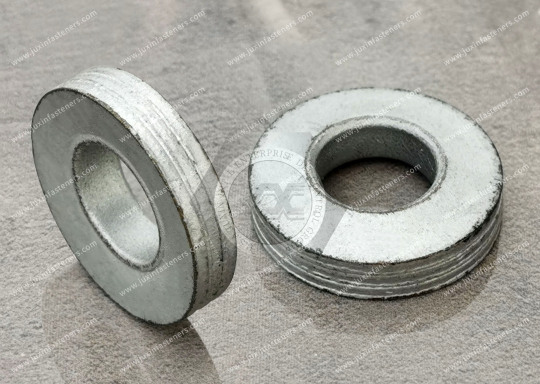

2. Conical spring washers: conical spring washers of the anti-loosening principle in the spring washer flattened, the spring washer will produce a sustained elasticity so that the inner threads of the nut and the bolt between the external threads produce contact pressure, This pressure produces friction resistance moment, thus preventing the nut from loosening. Conical spring washers have a higher stiffness than open-ended elastic washers, which means that the pressure generated by the same amount of compression is greater, and the anti-loosening effect is better. Application: Not applicable to connections with high preload requirements.

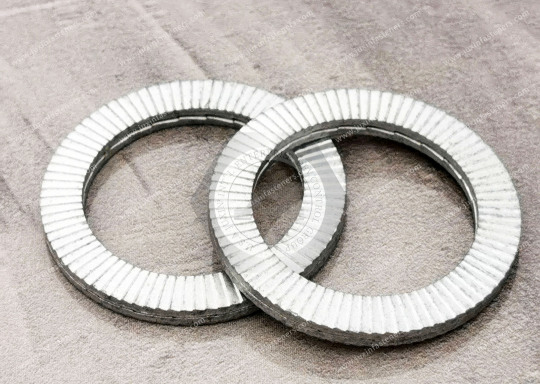

3. Double-stacked self-locking washers: One side of this washer has a large beveled tooth surface, in the other side of the washer has radial serration. nord-lock washers a large tooth surfaces relative to each other, installed in pairs. When tightening the bolt or nut, radial serrations bite tightly on the contact surface, so that the NORD-LOCK washer respectively with the nut and the connecting parts of the contact surface relative to the fixed, only allows the relative movement between the large oblique teeth. Any tendency for the bolt or nut to loosen is prevented by this wedging effect of the large serrations. The lifting distance between the two NORD-LOCK washers is greater than the lifting distance of the bolt or nut caused by thread sliding. Application: It cannot be used in connections where the connection surface is particularly hard. When the connection surface is particularly hard, the radial serrations are unable to bite into the contact surface and do not act as an anti-loosening agent. Washers have positive and negative, if the installation of the reverse will not play the role of anti-loosening, no pre-tensioned connections can not be used. The connection is too soft to use this washer.

If you are looking for high-quality fastener screws &all kinds of washers or technical support for structural design, please contact me. Thanks. Email: [email protected],

MyWhatsApp:+86-13660079809, Website:www.juxinfasteners.com

Facebook/ INS:[email protected]

#Spring Washers Anti-Loosening Principle#Conical Spring Washers#Double Stacked Self-Locking Washers Industrial Application Solutions

0 notes

Text

The usual fastening methods of the vehicle fasteners include bolts, screws, double-headed studs with nuts or threaded holes, self-tapping screws with prefabricated holes, clip pipe clamp embedded, and clamping ring hoop.

Its main application features are as follows:

The type of bolt, screw, double stud, and nut or thread hole matching is mainly used for high-strength connection pair with large loads, which has the characteristics of simple structure and stability.

self-tapping screw and prefabricated hole matching types are generally used for lightweight objects, such as the interior and small electrical parts fixed on the metal sheet.

buckle, pipe clamp type plastic fasteners are generally used to wire harnesses and other small diameter pipes fixed into the sheet metal class.

Clamp ring hoop for low-pressure hydraulic system or pressure system, cooling pipe, and so on. The strength and friction coefficient of each bolt is clearly defined, and the preload it can provide varies according to different torque strategies, but under a certain torque strategy, its minimum preload can be determined. After obtaining the minimum preload required by the connection point, and comparing which specifications of bolts can provide a minimum preload greater than it, you can choose the most economical specifications and performance levels. The following are the general steps for selection:

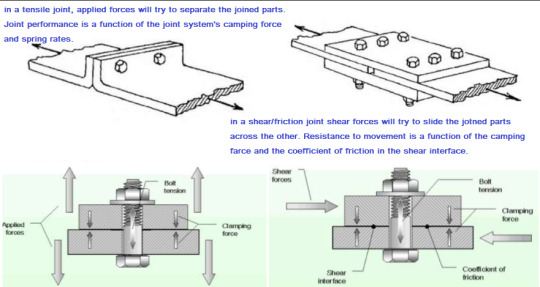

Determine the connection: tensile load, shear load, or composite load.

According to the connection mode to determine the connection sub-working load;

Calculate the axial load and tangential load borne by the bolt;

Determine the minimum clamping force;

Check the surface pressure of the clamping part to prevent crushing;

Determine the appropriate specifications and performance levels.

If you are looking for high-quality screws and fasteners or technical support for structural design, welcome to contact me. Thanks.Email:[email protected]

My WhatsApp:+86-13660079809,

Website: https://www.juxinfasteners.com

0 notes

Text

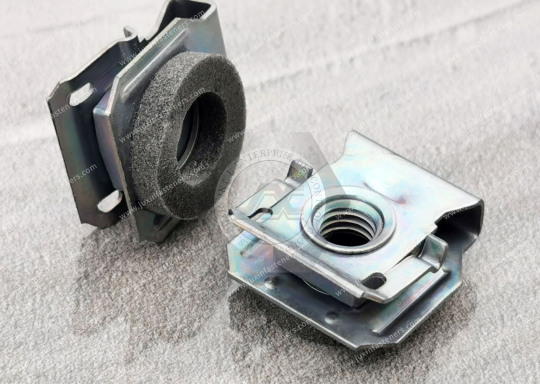

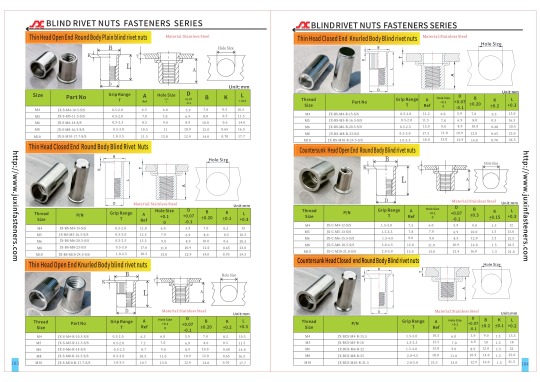

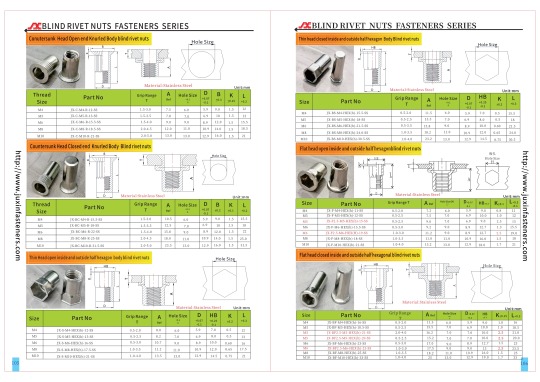

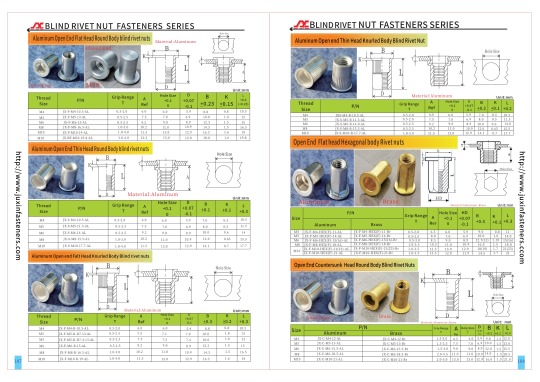

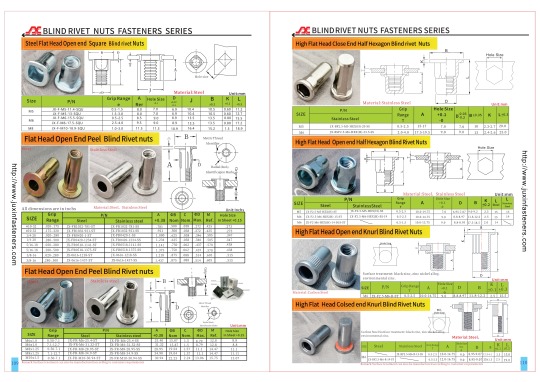

A blind rivet nut is a type of nut that is used to hold two or more thin plates in place, usually in automotive sheet metal fabrication.

1. M3 blind rivet Nut: M3 rivet nut is suitable for sheet metal processing, usually used for fixing automobile wheel arches, doors, roofs, and so on. It is characterized by a compact structure, easy installation, and stable quality, and can effectively strengthen the structural strength of sheet metal.

2. M4 blind rivet nut: M4 rivet nut is suitable for thicker sheet metal, especially for reinforcing automobile chassis and body structure. It is characterized by large bearing capacity, easy installation, not easy to loosen, and can effectively improve the overall stability of the car.

3. M5 blind rivet nut: M5 rivet nut is suitable for reinforcing the internal components of the car body, such as automobile dashboards, seats, and so on. It is characterized by a simple structure, reliable fastening, easy installation, and can effectively improve the overall safety of the car.Precautions:

1. The installation of blind rivet nuts should be carried out in accordance with the specified steps so as not to affect the firmness and safety of the threads.

2. When choosing the model of the blind rivet nut, it is necessary to choose according to different application scenarios and processing thickness, to avoid using too large or too small models, which will affect the performance and effect.

3. When using stainless steel blind rivet nuts, we need to pay attention to their quality stability and rust resistance to ensure their service life and stable performance. If you are looking for high-quality screws and fasteners, Technical support for riveting equipment or technical support for structural design, welcome to contact me. Thanks.Email:[email protected]

My WhatsApp:+86-13660079809,

Website: https://www.juxinfasteners.com

0 notes

Text

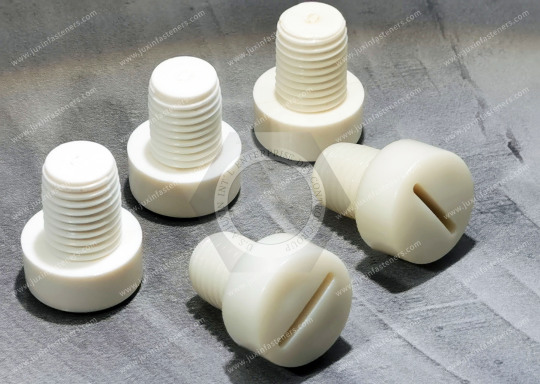

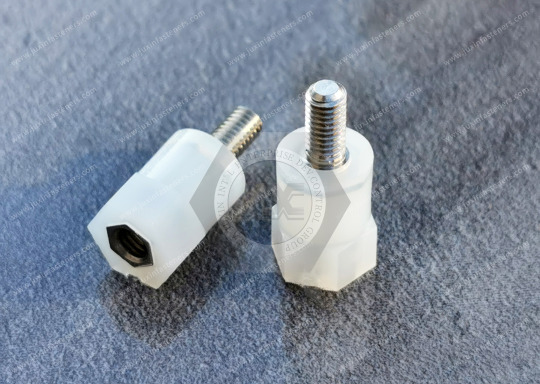

Polytetrafluoroethylene (Teflon or PTFE) Industrial Application Characteristics Structural Design Solutions

Polytetrafluoroethylene (Teflon or PTFE), commonly known as the "king of plastics", is a polymerized polymer compound made of tetrafluoroethylene. Used as engineering plastics, they can be made into PTFE pipes, rods, strips, plates, films, etc. It is generally used for corrosion-resistant pipes, containers, and other materials. Generally used in corrosion-resistant pipes, containers, pumps, valves, radar, high-frequency communication equipment, radio equipment, etc. It has excellent overall performance, high-temperature resistance, corrosion resistance, non-stick, self-lubricating, excellent dielectric properties, and a very low coefficient of friction.

Mainly has the following characteristics.

1. High-temperature resistance: working temperature up to 250℃.

2. Low-temperature resistance: good mechanical toughness; even if the temperature drops to -196℃, it can maintain 5% elongation.

3. Corrosion resistance: inert to most chemicals and solvents, resistant to strong acids and alkalis, water, and various organic solvents.

4. Weathering resistance: it has the best aging life among plastics.

5. High lubrication: the lowest coefficient of friction among solid materials.

6. Non-adhesion: It has the lowest surface tension among solid materials and does not adhere to any substance.

7. Non-toxic and harmful: physiologically inert, as artificial blood vessels and organs implanted in the body for a long time without adverse reactions. The surface of a medical catheter is smooth, non-toxic, odorless, and resistant to sterilization. Especially the medical catheter for internal use does not contain harmful soluble substances and has excellent organism substitutability, biocompatibility, and blood compatibility. It is widely used in aviation, aerospace, atomic energy, electronics, electrical appliances, chemical industry, machinery, construction, textile, medicine, and other industrial sectors and daily life. In particular, the industrial application of PTFE materials in anti-corrosion has greatly promoted the development of the chemical industry. If you are looking for high-quality PTFE fastener screws&all kinds of nuts or technical support for structural design service, please contact me.Thanks.Email:[email protected],

MyWhatsApp:+86-13660079809, Website:www.juxinfasteners.com

Facebook/ INS:[email protected]

0 notes

Text

Solutions for anti-theft Security screws

No matter whether in industry or in life, anti-theft screws are inevitable. It has both a fastening effect and an anti-theft effect.

Anti-dismantling, anti-theft screws protect objects connected to fasteners. Such objects are generally located outdoors for a long time, and most of the time they are left unattended, so the possibility of being disassembled and stolen by others is relatively high. And this kind of anti-theft screw is used for the performance of this disassembly. In simple terms, it needs a specific tool to remove a specific screw with good anti-theft performance.

Easy to use. Generally speaking, the stainless steel imitation screw and its wrench are equipped at the same time, so you don't have to worry about the characteristics of the screw making it impossible to use. Installing this kind of screw in an ordinary screw is no different. The overall difference is that the wrench used is different, and for most screws, this kind of screw is sometimes even easier to remove than ordinary screws.

Performance of anti-theft Security bolts:

They can be installed or uninstalled, including internal pentagonal anti-theft bolts, internal plum blossom anti-theft bolts, Y-type anti-theft bolts, external triangular anti-theft bolts, internal triangular anti-theft bolts, two-point anti-theft bolts, eccentric holes anti-theft bolts, and so on.

Installable and non-removable anti-theft bolts, including one-word anti-theft bolts (S-type anti-theft bolts), carriage anti-theft bolts, and so on. If you are looking for high-quality fastener screws&all kinds of nuts or technical support for structural design, please contact me.Thanks.Email:[email protected],

MyWhatsApp:+86-13660079809, Website:www.juxinfasteners.com

Facebook/ INS:[email protected]

0 notes

Text

Commonly used forms and principles of locking:

In fastener connections, there are four most commonly used forms of anti-loosening: friction anti-loosening, mechanical anti-loosening, destruction of threaded vice anti-loosening, and chemical bonding anti-loosening. Friction locking because of its simple use, ease of installation, and high degree of standardization, repeatable use, so it is the most widely used form.

1. Friction anti-loosening principle: by letting the threaded connection between the vice always have not with the external load and change the large enough positive pressure, in order to produce the friction to prevent the relative movement of the threaded vice, so as to achieve the role of anti-loosening.

Such as spring washers, self-locking nuts, and nylon self-locking nuts.

2. Mechanical anti-loosening: the use of stop elements, and direct locking, so as to limit the relative movement between the threaded vice. Due to the stop element and threaded fasteners acting surface, there is a certain gap, so when the stopping effect, the connection has occurred to a certain degree of loosening, so the effect on the tightening of the anti-loosening is almost no, only plays a role in preventing the fasteners from loosening.

3. Destruction of the threaded sub-loosening: this is in the fastener after tightening, through the punch riveting, welding, and other forms, so that the threaded sub can not rotate loosening. This form of anti-loosening effect is good, but the assembly efficiency is low, with no reusability. Therefore, in the case of large-scale high-efficiency installation, rarely used.

4. Chemical bonding anti-loosening: this is through the form of pre-coated anaerobic adhesive or now coated with anti-loosening adhesive, in the threaded sub-installation screwed into the form of pre-coated capsules, the formation of a certain degree of strength and toughness of the thermosetting plastics, fully filled with threads engaging gap, thus playing a role in restricting the rotational movement of the threaded sub in order to achieve the locking anti-loosening effect. This form of anti-vibration anti-loosening effect is good, while there is a certain sealing effect, under certain conditions can be reused, but disassembly is more difficult. Design engineers in the selection of anti-loosening measures and anti-loosening fasteners, as a reference. If you are looking for high-quality fastener screws&all kinds of nuts or technical support for structural design, please contact me.Thanks.Email:[email protected], MyWhatsApp:+86-13660079809, Website:https://www.juxinfasteners.com/

Facebook/ INS:[email protected]

0 notes

Text

Stainless steel lamp hardware processing non-standard parts turning and milling composite CNC lathe processing.

Engaged in precision machinery core parts processing, and manufacturing, mainly including communication equipment, photoelectric equipment, ceramic machinery, woodworking machinery, medical machinery, packaging machinery processing manufacturing, and sales, processing aluminum precision parts, non-standard precision parts, stainless steel precision parts, automotive precision parts, communication equipment precision parts, medical equipment precision parts, etc. For high precision parts can be completed at one time turning and milling, without secondary processing, to ensure concentricity and precision. If you are looking for high-quality CNC machining parts or technical support for structural design, welcome to contact me. Thanks.Email:[email protected],

My WhatsApp:+86-13660079809,

Website: https://www.juxinfasteners.com/

Facebook / INS:[email protected]

0 notes

Text

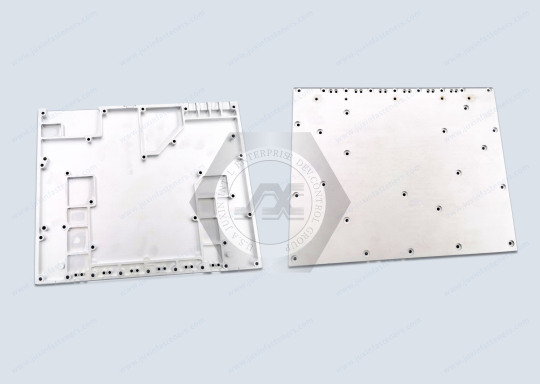

Stainless Steel Machined Parts Solutions for Industrial Electrical Cabinets in the Manufacturing Sector: Discover our comprehensive stainless steel machined parts solutions for industrial electrical cabinets, including PLC control cabinets, inverter control cabinets, push-button cabinets, MCC combination cabinets, outdoor waterproof cabinets, and more. Explore applying precision sheet metal design and stainless steel machining components for efficient and reliable control cabinet solutions. In the manufacturing sector, the industrial electrical industry relies on robust and reliable control cabinets to ensure seamless operations. Our company specializes in providing comprehensive solutions for industrial electrical cabinets, integrating precision sheet metal design and stainless steel machined parts. With a focus on quality and functionality, we deliver efficient control cabinet solutions that meet the diverse needs of the industry. For the industrial electrical industry, our comprehensive solutions for control cabinets, incorporating precision sheet metal design and stainless steel machined parts, offer reliable and efficient solutions. From PLC control cabinets to outdoor waterproof cabinets, our expertise in customizing stainless steel components ensures optimal performance and durability. Contact us today to explore how our precision machining capabilities can elevate your industrial electrical cabinet solutions, providing reliable, corrosion-resistant, and customized control cabinets for your specific applications. If you are looking for high-quality CNC machining parts or technical support for structural design, welcome to contact me. Thanks.Email:[email protected],

My WhatsApp:+86-13660079809,

Website: www.juxinfasteners.com

Facebook / INS:[email protected]

0 notes