Text

The Ooho

According to consulting firm Euromonitor, in every minute of 2017, one million bottles were purchased and 91% were not recycled. As consequences of humanities endless consumption start to charge the planet, more and more solutions towards diminishing the use of packaging have grown.

The product to be analyzed today is The Ooho. In the lack of better words, as the own company also presents it, it is a blob of water. It was founded by Rodrigo García Gonzalez and Pierre-Yves Paslier. They both have engineering backgrounds with focus is design and had many interactions with innovative and developing projects. They started to think towards a solution after watching a marathon race and observed the enormous amount of bottles runners left on the floor - a common action that is consequence of the high pressure the athletes are in. Through the kilometers, there are water stands that distribute water for the athletes; who get the bottle, open them while running, drink them and leave on the floor. The final scenario is beyond horrifying but acceptable since it has just happen to function in that manner.

And even though the founders of Ooho had their inspiration through a marathon environment, the question itself is not new for those who strive to solution the increasing pollution of plastic on our planet. How can we drink liquids without bottles? There are brands that make them of paper, and there is a great movement towards encouraging people to always carry their personal not disposable bottle but still, the bottle consumption is enormous.

Inspired by this situation, the developers came up with the product Ooho - meant to revolutionize marathons and even the whole beverage market. It consists in a bubble made of seaweed extracts with any liquid you wish inside. Almost like a small edible balloon. The idea was, you are running, you grab a blob of water as you would do with a bottle and just eat/drink it.

youtube

If not consumed, the blob can hold for four to five weeks before disintegrating without leaving any footprint and currently can be manufactured up to 2,000 per day.

It is an exciting invention that really solves the bottle problem. All that is needed now is to change our culture of consuming beverages and maybe we can improve our impact on this planet.

Sources:

http://www.skippingrockslab.com/ooho!.html

https://www.earthday.org/2018/03/29/fact-sheet-single-use-plastics/

0 notes

Text

The Hoverglide Backpack

For my first entry in this journal I chose to analyze the Hoverglide Backpack. The backpack in question is produced by the brand Lightning Packs LLC, founded by Dr. Lawrence Rome. He is a biology professor in the University of Pennsylvania and an expert in muscle physiology. This project comes a long way since 2002, when the Office of Naval Research contacted the professor requesting a technology that would capture energy through movement since Special Forces in Afghanistan were carrying 100lbs in their backpacks being 20lbs just the batteries.

youtube

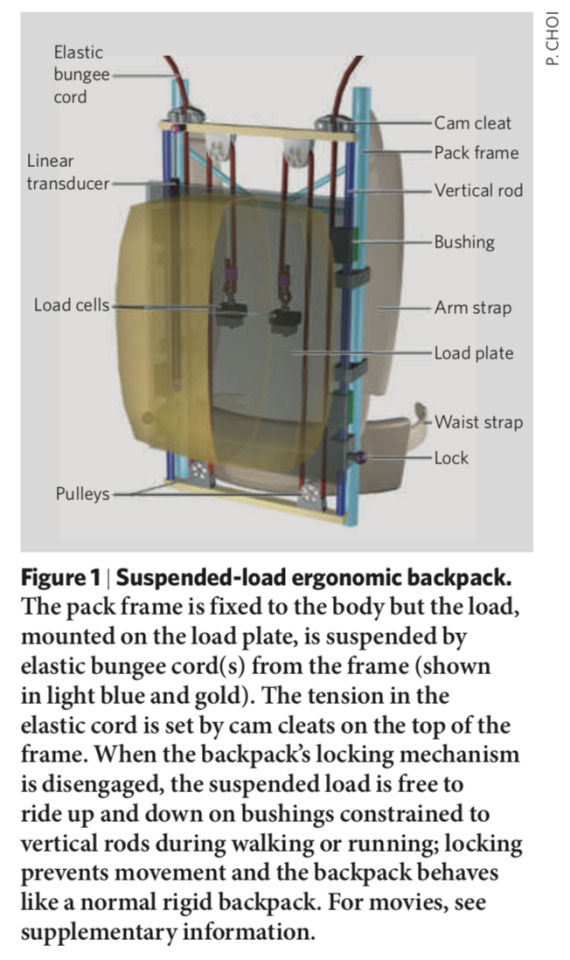

By 2004 he filed for patents for the SLT (Suspended Load Technology) and published his findings of how he and his team developed the technology that converts mechanical energy from vertical movement of carried loads to electricity (Rome, Flynn, Goldman & Yoo, 2005). While experimenting with the SLT technology he observed that the testing subjects preferred walking and running using the SLT backpacks, so he developed a backpack without the energy generator to what became the first Hoverglide backpack. Through studies he realized that the backpack reduced impact of load carrying, relieving joints and sparing the user’s energy.

When observing the Lightning Packs LLC products, it is very clear that the main objective is to relief load carriage. They have four backpack models: one large 55l hiking backpack named The Trekker and three medium models that can hold from 28l -30l; The Tactical, that aims for first responders and military, The Hiker, focused for outdoor activities and The Commuter, focused in urban usage. In order of reducing impacts of load carriage, all of the models have the SLT frame (that don’t include the energy generator). In 2006, Dr. Rome published the mechanics behind the frame and basically it uses bungee cords to suspend the load and according to the user’s movement reduces the vertical force on the carrier (Rome, L., Flynn, L., & Yoo, 2006).

So when observing someone using a backpack with the Hoverglide technology, it seems that the user is moving and the load does not follow the body, remaining in the same height as when the user was still. All the backpacks are made with ripstop Nylon with DWR finishing and when comparing the models, the biggest differences are how they were designed to attend the necessities of each activity by having different compartments on the inside and pockets on the outside. Except for The Trekker backpack that has the biggest carriage capacity and The Tactical that has a MOLLE (Modular Lightweight Load-carrying Equipment) applied on the front, The Hiker and The Commuter are pretty much the same, maybe attending a market necessity with different designs aiming two different consumers.

Even though the product seems to have much science behind and heavy marketing with videos and citations, one can be suspicious of the product’s efficiency. The movement of the backpack produces quite an estrangement for observers because it does not seem natural. But, according to the company’s website, it already has military use since 2011, which may be a legitimate evidence that the product works. The only issue that is clearly stated is that if the user wishes or comes to the need of carrying a weight above the indicated (55lbs or 30lbs) the frame will not work and the pack must be locked; which makes sense because the bungee cord mechanics is thought to nullify a specific load.

All above being said, this product came to my interest foremost because of a well produced campaign video, with activities being filmed and the technology clearly demonstrated. I believe the product is entirely appropriate for human factors study since it presents a solution to a daily issue that in my opinion is experienced by almost everyone during lifetime and maybe can be a easily accessed technology for many brands. I specially see this technology in use for outdoors activities because they usually require the user to carry a great deal of weight for medium to long periods.

Sources:

Rome, L., Flynn, L., Goldman, E. & Yoo, T. (2005). Generating Electricity While Walking with Loads. Science. 309, 1725-1728.

Rome, L., Flynn, L., & Yoo(2006).Rubber bands reduce the cost of carrying loads. Nature. 444, 1023-1024.

https://www.indiegogo.com/projects/hoverglide-world-s-first-floating-backpack#/

0 notes

Text

Levi's® Commuter X Jacquard By Google

By this time being sold in Levi’s online stores, this piece of apparel generated quite an excitement in the smart technology market. And everything in technology seems to lead us to smarter gadgets. Incorporated in our glasses, shoes, watches, clothes. All want to provide a natural and individual service to each user. And the project that unites the north American brand Levi’s and Jacquard Project, arm of the Google ATAP (Advanced Technology And Projects) tried to offer exactly that, focusing in the biking commuter user.

The project has been around in talks since 2015 among the topic of smart fabrics. The goal was to make a jacket to serve as an assistive technology while you are riding your bike. The challenge at that time was that they wanted a jacket that looked and especially felt like a regular jacket, meaning by that, washable, flexible and no wires loosen around.

To achieve their goal they first had to come up with an realistic plan to make it manufacturable. The apparel industry is one of, if not the eldest in the world. We make most of our daily fabrics the same way we did a hundred years ago. Machines get faster, smaller, but the idea behind them continues the same. And to solve that they actually developed a thread that has copper inside and is touch responsive. Weaved within common yarns of jeans, the development team was able to introduce what seems like a circuit inside a fabric.

And through this fabric, that was precisely applied on the cuff area the user can answer their phone, play and pause music, initiate a route through GPS and do realize basic commands by moving your hand through the jacket.

The issue with smart gadgets today is that they come in pricey terms to the little they offer. The jacket today costs around 350 USD. And even though I personally believe this is more of a door of technology that is opening to come to develop many other solutions and inventions, there really is no reason to buy it.

youtube

youtube

Sources:

https://www.levi.com/US/en_US/clothing/men/outerwear/levis-commuter-x-jacquard-by-google/p/286600000

https://atap.google.com/jacquard/

https://www.youtube.com/watch?v=G9ADVeNpypk

0 notes

Text

Kingii Wearable

A product that is looking to introduce safety in watersports niche. The development of Kingii is due to a personal story regarding its creator, Tom Agapiades. According to him in the product’s website, he lost a dear friend in a lake, as he swam around fifteen yards into it and got in trouble. His friend was a skilled swimmer, the lake seemed to show no danger whatsoever but still a tragedy occurred. And it is not an exception story; in 2015 when the product was launched, according to the United States Center for Disease Control and Prevention, 530 people drowned and from those 100 were children, under the age of fourteen. Unfortunately signals that indicate that a person is drowning aren’t always clear. In most of the cases above, there was a lifeguard or supervisor in the scenario.

“When you drive a car, you put your seatbelt on. When you ride a bike, you put on a helmet. But how do you protect yourself in the water?” asked Tom Agapiades, inventor of the Kingii (pronounced KIN-jee). “No one swims around with a lifejacket on, and that’s when they get in trouble.” - Tom Agapiades. Especially athletes that usually don’t use lifejackets because it causes discomfort while practicing a sport.

Thinking on the scenario above Tom visualized a gear that would not cause much disrupting in the body movements, that should be easy to wear and lightweight. The final product resembles a bracelet (still bulky, but better than a lifejacket) that has a rectangle on top and a lever on the side. Inside the rectangular box, the inflation bag sits folded, which is activated when pulling the lever and a CO2 cartridge fills up the bag. It even is incremented with a small compass on the wristband and a whistle attached to the inflation bag. The product comes with two CO2 cartridges, one for training and one for real emergencies. When activated, the bag will inflate, popping out from the box and taking the user to the surface in seconds.

The only issue with the product is that it relies on the user being conscience. Many drowning situations happen because the person loses conscience under water. By that, in my opinion it seems to still be a better option for children to use floaters and lifejackets. But for athletes I think it is a quality product since in the current scenario they go into the water without any safety gear.

youtube

Sources:

https://www.kingii.com/index.html

https://www.cdc.gov/HomeandRecreationalSafety/Water-Safety/waterinjuries-factsheet.html

https://well.blogs.nytimes.com/2015/08/18/technology-to-keep-swimmers-safe/

0 notes

Text

Perfectfit Pointe

Perfectfit Pointe is a late resolution to one of ballet dancer’s biggest problems.

Ballet is a more than a century year old form of dance, and basically it is about performing movements on the tip of your toes. The dancers will jump, tip toe, make splits, pirouettes and land choreographies day and night. When the objective is to become a professional, dancers will submit to training almost every week, many hours per day. It requires muscle, strength, balance and resilience. Using specific shoes, the satin covered flats with a small block of plaster on the front, allow ballet dancers to create what they called “en pointe”. They were thought to make the dancers appear weightless, since balancing on the small pointed area shoe made it look like so.

Unfortunately, in order to master the art of Ballet, dancers will almost always sacrifice their feet. Most dancers loose toenails, have deformed feet and deal daily with blisters and purpling flesh. And beyond those, there are the impacts of putting so much force on the joints resulting in twisted ankles, knee displacement, hip displacement, broken bones… The culture of Ballet normalized suffering, and between stages, pain is part of the craft.

One of the main reasons dancer’s feet are so injured is because it takes a lot of pressure. When standing on the tip of your toes, all the weight of your body focuses in this small area. When training at this level, even having the feet’s index toe bigger than the big toe probably means you will lose it. The best feet format a ballet dancer can have is a squared one, where all the toes can take pressure equally. But since squared feet aren’t the most common, dancers will turn to every strategy possible to create this balance. Stuffing fabric around the shorter toes, using paper, wrapping them in tape, and even some extreme decisions such as simply eliminating problematic nails. And having your feet balanced inside the shoe not only means less injuries on the feet but also prevents the really serious injuries; when in “pointe”, since all the weight goes to one point of the body making it unbalanced, it is easier to twist an ankle, and hurt joints generally.

That is where the product Perfectfit Pointe comes to scene. It is a very simple product, but strangely there aren’t many improvements in ballet industry. All gear is practically the same since 1930, when the pointe shoes were invented.

Perfectfit Point was invented by Kelly Schmutte, an engineer, designer and herself a ballet dancer. The product consists in a DIY (do it yourself) kit, where the user receives a mold and one mix of two-part silicone rubber that when mixed becomes a dough. After mixing it, the dancer will pour it inside the mold and let it dry around the feet’s form. When dried, the silicon-rubber will fill out the different heights of the toes, deliver an impact absorbent material and it is truly individual, solving all the problems listed above that are directly toe concerned.

youtube

Sources:

http://perfectfitpointe.com

https://www.nytimes.com/2018/01/12/jobs/change-ballet-toes-shoes.html

Smith, T., Davies, L., Medici., Hakim, A., Haddad, F. & Macgregor, A. (2016). Prevalence and profile of musculoskeletal injuries in ballet dancers: A systematic review and meta-analysis. Journal of Physical Therapy in Sport, 19, 50-56.

0 notes

Text

Moisture-responsive Clothing

The moisture-responsive workout suit is a MIT project that proposes clothing that self-ventilate. Using bacteria found in fermenting beans (Bacillus subtilis) and accounting for its response to moisture, they used the expansion/contraction capacity the bacteria has to create movement. The fast-growing bacteria was bred in bio reactors and gone through processes that enabled the scientists to infuse them inside a what looks like glue, that with a printer that resembles a 3D printer, can dispose lines of “bacteria glue” through fabric, predicting how they will move. The final fabric would look like a surface with scales that open and close, and they are safe for human to wear near the body and even consume.

To apply the technology, the team had to develop a program that analyzes the body heat map and sweat map to after develop a program that understands the directions the bacteria goes, creates a pattern of scales with the nano activated material. By placing the fabric with the scales in areas like top middle of the back and chest, when the user starts sweating the cells immediately open up, creating a mechanical ventilation for that body area. The experiment was received with much enthusiasm, because it has many areas of use such as the own experiment, the apparel industry, but also medicine, architecture and many others.

But as for apparel the only issue in my opinion is that for the mechanism to work, the fabric must be doubled; on top of the fabric with the bacteria, there must be a second fabric that apparently it is used to hold everything together, which may prejudice breathability of all the other parts of the garment that don’t have the opening scales. The second, is that the scales don’t close perfectly, indicating that the garment has two forms, ventilated and even more ventilated, since the scales closed don’t actually prevent air to come inside. That would make it difficult to use the technology in cold environments or activities that involve wind. And as for warm environments, a garment with a light open mesh would probably deliver the same result.

One part of the experiment that probably seems more exciting is the prototype the team made for a sneaker, that as mapping the sweat areas discovered that the part of the feet that sweats the most is the sole. By placing the scales under the feet, they can ventilate when the user is exercising, and since that part of the sneaker is rigid, there is a chance the scales can be more efficient and less impacted by movement or wind.

youtube

Source:

http://advances.sciencemag.org/content/3/5/e1601984

http://news.mit.edu/2017/moisture-responsive-workout-suit-0519

https://www.youtube.com/watch?v=eb6kbVPHHjE

2 notes

·

View notes

Text

The Shoe That Grows

The Shoe That Grows is pretty much… A shoe that grows.

Idealized by Kenton Lee from Nampa (Idaho, US) it all started when after finishing college Lee decided to explore the world through volunteer work. He ended up working and living in an orphanage in Nairobi, Kenya. While working there, according to himself, he spotted a child wearing shoes so small for its feet that the front was cut off so that the toes could fit. And from there he started observing that most of the kids did not have a shoe that fitted.

After making his way back to the US, he decided he would develop a product to fit the need of those children. He spent 5 years developing the product and raising the company and an interesting fact; he wore the same shoe for 5 years in a commitment that he wouldn’t change shoes until his project came out of the paper.

The shoe is made of leather and the sole is compressed rubber, thick materials that ensure the product lives the span of five years. In what could be compared to a sandal in form, using buckles, Velcro (older models had snaps on the sides) and pins the sandal expands in all side directions. In the front you have a pin, on the sides the Velcro and on the back a buckle. It comes in two sizes, the small one fitting children from four to nine years old and a large, for ages raging nine to fourteen years old. Regarding production, the company also targets countries that are located in more needed areas, the shoes are manufactured in Kenya, Ethiopia and Haiti.

By making this product accessible for kids in vulnerable areas, which are remotely located, poorly sanitized and have no medical service available, the shoe has a huge impact in an infant’s life. Protecting their feet against diseases that are transmitted through the feet’s sole and from rough terrain increases their quality of life. Healthy kids go more to school, have more dignity and are less vulnerable.

It is really interesting to see a product tackle some many problems at once. It is a great example of how a product can change the surroundings. From manufacturing processes that are directed to troubled areas, using a volunteer network to distribute the shoes, using durable materials that won’t be disposable in a short period leading to even bigger landfills and the whole five years shoe that will be actually useful and improve the user’s life.

youtube

Source:

https://theshoethatgrows.org

https://www.youtube.com/watch?v=NpFb7eGt-4g

0 notes

Text

Qube Basketball Ball

For this entry we will be analyzing the basketball ball Qube - a squared ball. Created in Louisville (Kentucky US) by one-time high school basketball star and today teacher/ coach in Saint Louis University, Charlie Wallace. During one of his training sessions, he observed the position of a student’s hand and pictured a perfectly square shape. From that exercise he realized that he could correct student’s position and improve their relationship with the sport as, according to him, “basketball is more fun when you score”. Facilitating the playability, he had more chances of having engaged students and maybe athletes.

The polyhedral shaped square ball is the same size and weight as an actual basketball ball. The main objective is to aid amateurs and even professionals in perfecting the movement one makes as aiming the ball into the net. Through muscle memory and practice, the cubic shaped ball forces the users to correct the positioning of hands, joints and limbs. While standing to aim the net, in order for the Qube not to fall, it must be perfectly straightened in the user’s hand and as directed to the net straightly, the wrist will also be positioned correctly. For e.g. imagine a person holding a tray with objects on top; for them to not fall the tray must be parallel to the ground. If the person wants to throw to objects in a straight direction it would need to rotate the wrist and position the elbow. By that, the user will be improving into a perfectly straight shot and since the position is correct, all one has to do is discover how much force is needed to conclude the trajectory of the ball into the net.

As a patented product already being used in different countries, as a sports training aid it seems very efficient. By training users with an objective, clear visual feedback and by forcing them into correct positioning the learning process becomes less frustrating and it eases the coach’s work when the user is not entirely conscious about its body movement and position. As the user utilizes the product, he alone can adjust his body and not throw various times hoping to get a right shot and then trying to copy it. It is related to human factors since it is a product developed thinking of the human nature that is capacitated by senses of touch, grip and balance.

youtube

Sources:

https://www.qubebasketball.com

https://patents.google.com/patent/US20160325166A1/en

http://www.wdrb.com/story/34732404/louisville-native-develops-device-to-achieve-perfect-shot-in-basketball

0 notes

Text

Sheerly Genius Pantyhose

For this analysis today, we will be looking into a start-up called Sheerly Genius, founded by Katherine Homuth, a serial entrepreneur. The product offered by Sheerly Genius is a rip proof pantyhose. According to the company’s website, the invention was driven by the dissatisfaction and frustration with regular pantyhose that easily rip within any surface friction. They can also be called stockings, tights, hosieries and even socks. It is a common piece of apparel for women and the contemporary version of it has been around since 1940 with the invention of Nylon by Dupont (Viswanathan, 2010).

By researching military and outdoor apparel, Katherine Homuth started to envision what would be the indestructible pantyhose. The first problem was that fibers strong enough to achieve the objective were too thick, had no elasticity, weren’t dyable and they were extremely expensive. Facing those, the company had to actually develop a fiber, and after around a year of research and development, they succeeded. They claim the fiber is 10x stronger than steel, lighter than water, bacteria resistant and solved the elasticity and dying problem. Unfortunately, the fiber is still pending patent, so there is no information on its composition whatsoever, but the results seem convincing.

With all those issues solved, Sheerly Genius was able to innovate the pantyhose for every woman. Even though the cost of the product is higher (99USD), they claim the product can handle up to 50 wears. Considering that, if you do the math that a regular pantyhose costs around 14 USD and can be worn (if lucky) around 2 times, it is a worthy product. Not only you can rely on the product like most of apparel offered in the market as how it is considerably more sustainable since the user will be consuming less products. And nylon recycling is not evolved enough to worth the high production we have for this product today.

This product is interesting because it shows that there are many daily products we use that can be bettered. Pantyhoses have been around forever and also been discarded forever, and many women have had issues with this product at some point. Just to spare them of buying a pantyhose and unluckily rip them in the first use because one might forget to take their rings off adds so much to the user experience. There is nothing worse than using a piece of apparel that surely will fail at some point.

youtube

Sources:

https://www.kickstarter.com/projects/sheerlygenius/indestructible-sheer-tights-made-with-bulletproof

https://www.indiegogo.com/projects/indestructible-sheer-tights--3#/

https://sheerlygenius.com/pages/order

Viswanathan (2010). Wallace Carothers: More than the inventor of Nylon and Neoprene. World Patent information. 32, 300-305.

0 notes