#washers

Photo

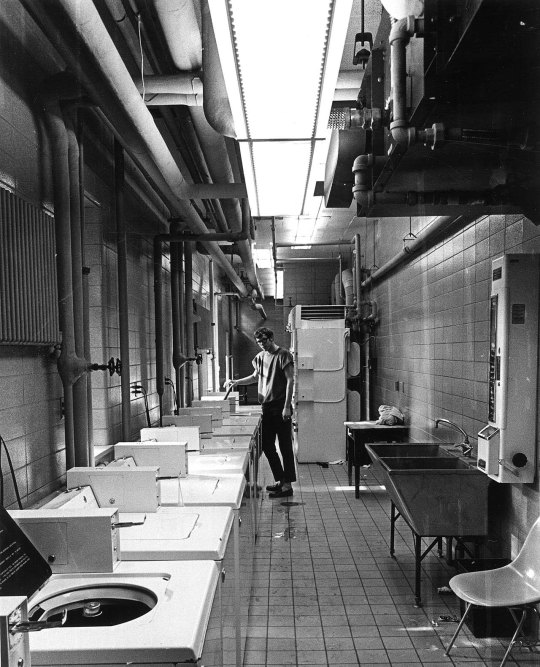

Laundry room in Hillcrest Hall, The University of Iowa, 1965

Creator: Kent, Frederick W.

https://digital.lib.uiowa.edu/islandora/object/ui%3Aictcs_14956

#Residence Halls#Dormitories#Hillcrest Hall#Laundry Rooms#Sinks#Vending Machines#Washers#Dryers#Doing Laundry#Radiators#Lights

16 notes

·

View notes

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Text

Premium Quality Washers Manufacturer in India - Ananka Group

Ananka Group is one of the top Washers Manufacturer in India. Washers are important hardware components used in a variety of applications to disperse the load of a threaded fastener, such as a bolt or nut. These flat disk-shaped gadgets are usually composed of metal, plastic, or rubber. They have various vital roles in mechanical assembling and construction.

The primary aim of washers is to protect the surface of the material being secured while also ensuring a secure and uniform distribution of the applied weight. Friction is decreased by inserting a washer between the nut and the surface, helping to avoid loosening and ensuring a more solid connection over time. This is especially important in cases where vibrations or movements may occur. Also, we are a leading SS Fasteners Manufacturer in India & Bolt Manufacturer in India

Washers are often utilised in construction, automotive, manufacturing, and other sectors that require dependable and secure fastening. Their basic but critical role in load distribution and damage prevention makes them important in a wide range of mechanical and structural applications.We are also a Best Leading and Selling Fastener Supplier in India

For more details:

Product Source:

Washers Supplier in India

0 notes

Text

Carbon Steel Large Plain Washers

Split, Wedge, Internal Tooth, External Tooth, countersunk, Bonded, countersunk, button head/ socket head/flat head

0 notes

Text

Screws: Uses and Applications

Fasteners like stainless metal screws are essential for fitting two pieces together. These fasteners find applications from everyday things to advanced machines. Screws are available in multiple types depending on their design, functionality, and applications. The following article explains the use of screws and their applications in different industrial sectors.

Uses of screws

Screws are one of the common fastener types, like stainless steel bolts and nuts, with extensive application in the construction sector. Screws are versatile and have excellent resistance. Following are some of the uses of screws:

Connecting the materials: Screws are essential for joining multiple materials safely and effectively, like assembly of metal structures, electronics, and furniture, as they offer a solid and lasting connection.

Connecting wooden elements: Stainless metal screws find extensive application in carpentry, construction, and assembly of furniture. The threads on the screws allow ease of insertion in the material and a stronghold.

Equipment and machinery assembly: Stainless steel screws are essential for assembling multiple machine pieces. These Stainless Steel 304 fasteners offer resistance to vibrations. The rotational torque on these screws makes it a top fastener choice for holding together machine parts.

Structural support: One of the top applications of stainless steel screws is building and bridge construction. These accessories are also useful for fixing columns, beams, and more. Screws offer a reliable and strong connection, ensuring the structure remains safe and sturdy.

Maintenance and repair: S.S. screws are perfect for applications requiring frequent maintenance and repair of the different system parts. Hence, they are used for repairing appliances, screws, and more.

Automotive sector: Fasteners like screws find applications in automobile manufacturing as they help assemble the automobile components like engines, body panels, suspension systems, etc. These accessories ensure safety and reliability.

Electronics: Screws are essential for the security of different elements in electronic devices like smartphones and laptops as they provide reliability and precision.

Construction sector: One of the top applications of S.S. screws is the construction industry. Screws are essential for operations like roofing, drywall installation, framing, and fixing fittings and fixtures.

Types of screws

Following are the type of screws available at a screw supplier

Wood Screws

Lag Bolts

Sheet Metal Screws

Hex Bolts

Hex Screws

Nylon Screws

Masonry Screws

Self-Tapping Screws

CSK Slotted Screws

Socket Head Cap Screws

Anchor Screws

Shoulder Screws

Fastener selection and installation

One must consider multiple factors during screw selection and installation. The fastener material, strength requirements, and applications are some considerations. Moreover, it is also crucial to seek consultation from experts at fastener manufacturers in India, like Fasteners & Fixtures LLP, regarding the right type and size of screw essential for your project. Following are some of the considerations for selecting and installing screws:

Material considerations: It is essential consider to the material on which the fastener is fastened. Choose a screw per the application.

Consider the thread type: The threads on the screws are a prominent part of the stainless steel fasteners as they decide the fastening mechanism. Stainless self-tapping screws are perfect for hard materials.

Consider the screw size: It is essential to choose the perfect size of the screws to guarantee a tight fit.

Use the right tools during installation: Fitting screws in a material require the perfect tools like wrenches or screwdrivers, ensuring a tight fit.

Pre-drilling operation: Pre-drilling can be best for fragile materials like wood to prevent splitting.

Right force: It is vital to apply only essential force during screw installation as low force can lead to loosening, while excess force can overtighten the screws and lead to breakage.

Final thoughts

Stainless steel 304 fasteners like screws find extensive applications due to their durable and reliable fastening. By understanding the fastener types, sizes, materials, and other factors, you can choose the correct fasteners and ensure safe installation. One must choose a reputed fastener supplier, ensuring you get the best quality products. Fasteners And Fixtures LLP is a leading stainless steel screw manufacturer offering extensive product variety, top material quality, and functional products. For more information, contact them today!

1 note

·

View note

Photo

Hey, Washers! Jess from Futur... https://www.xtremeservers.com/blog/a-sneak-peek-at-the-cool-animations-of-the-back-to-the-future-special-pack-for-powerwash-simulator/?feed_id=117006&_unique_id=65ab78d816f47&A%20Sneak%20Peek%20at%20the%20Cool%20Animations%20of%20the%20Back%20to%20the%20Future%20Special%20Pack%20for%20PowerWash%20Simulator

0 notes

Text

Just like the kites in the sky, may your dreams soar high this Makar Sankranti! Happy Makar Sankranti 2024 !!!

#HappyMakarsakranti#makarsakranti2024#AvtarIndustries#RealmodeAutoTech#Ubolt#centrebolts#springpins#bellcrankwasher#jackrods#Centrebolt#eyebolts#cotterpins#hubboltwasher#springpinwashers#wheelspanners#springpin#washers#Rearubolts#TataAceUbolts#hangershackle

0 notes

Text

A Beginner’s Guide to Washers: Elevate Your Laundry Game

No one can deny the importance of a good washer in their laundry routine. And with so many options available in the market, choosing the right one can be a challenge. But don’t worry, this guide is here to help you. We have rounded up everything you need to know about washers, so you can make an informed decision and elevate your laundry game.

Types of Washers

Let’s look at the different types of washers, their benefits, and how they work.

Front Load Washers

Front-load washers are becoming increasingly popular due to their modern look, energy efficiency, and low water usage. They work by using gravity to tumble clothes through a small amount of water, which makes them gentler on clothes than top load washers. As a result, front load washers are also the preferred choice for people who have delicate clothing items.

Top Load Washers

Top load washers are the traditional washing machines that load clothes from the top. They are considered easy to use and can handle a large amount of laundry at once. They are a popular choice in many American households because of their affordability. Additionally, top load washers are faster and more efficient than front load washers. This is because of the convenient settings that allow you to customize your laundry needs.

What to Look for in a Washer?

Load Capacity - The first thing to look for in a washer is the load capacity. This will depend on the size of your household and your laundry needs. If you have a large family, you might want to consider a washer with a load capacity of 5 cubic feet or more. On the other hand, if you live alone or have a small family, a smaller washer with a load capacity of 3-4 cubic feet might suffice.

Energy Efficiency - A washer that is energy efficient is not only good for the environment, but it also helps you save money on your electricity and water bills. A washer with Energy Star certification is more efficient than others and may be the better choice.

Noise Level - If you live in an apartment or a small house, you might want to look out for a washer that is quieter. It can be annoying to hear the washer running in the background while you’re trying to get some work done. Look for a washer with a low decibel rating to minimize the noise.

Modern Features - Choose a model with some of the most sophisticated features like steam washing, multiple wash & temperature cycles, and smart technology. Such washing machines allow you to do multitasking, thereby letting you save your precious time.

Snag Top-Quality Washers

It always serves you well to pick washing machines that have a reputation of giving the best performance.

Consider these front load washers - LG Front Load Washer, Samsung Front Load Washer, GE Front Load Washer & Electrolux Front Load Washer

Consider these top load washers - LG Top Load Washer, Samsung Top Load Washer, & GE Top Load Washer

Top-Loading vs. Front-Loading Washers

Top-loading washers are more traditional and often less expensive. They’re also more convenient for those with mobility issues. Front-loading washers are more modern, energy-efficient, and work well in tight spaces. They are also gentle on clothes and require less water. Consider your laundry environment and choose a washer that suits your needs.

Investing in the right washer is essential for any household. Each type of washer comes with its advantages and disadvantages. Choose the one that meets your needs, budget, and preferences. Don’t forget to consider size, durability, and energy rating when shopping for washers. With the right washer, laundry day doesn’t have to be a chore. Instead, it can be a seamless and efficient experience.

0 notes

Text

Toothed Look Washers | Look Washer | DIC

#toothedlockwashers#lockwasher#washers#exporter#industrial#exporterinindia#topexporterof toothedlockwahers#bussiness#exportersoftoothedlockwashers#dic#dedicatedimpexcompany

0 notes

Text

Laundry regret? We've all been there! 😓 But fret not, because Appliance Medic is your go-to destination for Samsung dryer repair services in New City, New York. Our expert technicians will have your dryer up and running in no time!

Visit http://bit.ly/3LhHC3j to book an appointment!!

#dryerrepair#dryernotworking#appliancemedic#newcity#ny#newyork#dryer#samsungdryers#samsungappliance#repairs#repairservices#washers#washingmachine

0 notes

Text

Stainless Steel Industrial Fittings

Simplex Steels is an ISO 9001:2015 certified manufacturing unit located in Ahmedabad, Gujarat, India.

Stainless steel industrial fittings manufactured by simplex steels are the most demanded fittings in the market.In an installation, people use them to connect the elements of an installation together and equip rigid pressure lines pipelines or flexible lines hoses.Clips, clamps, and crimping ferrules mount the fittings to the hoses.People use other types of assembly clips and clamps to attach the pipes and hoses to the base construction.Simplex Steels offers a wide range of industrial fitting products which are available in a variety of standard material.Manufacturers produce industrial fittings using stainless steel, making them dimensionally precise and equipping them with high functionality in any application area.Due to the optimum performance and impeccable design our, all the fittings are highly demanded industrial fittings in the market. Below is the list of our industrial fittings.Tube fittings

Pipes fittings

Washers

Flanges

Elbow fittings

Bend fittings

Reusable fittings

Banjo fittings

Reducers

Coupling

Hex nipple

Pipe nippleFeaturesCorrosion Resistant

High Tensile Strength

Very Durable

Temperature Resistant

Environmentally Friendly

Low-maintenance (long-lasting)

Attractive appearance

Long Durability

High Strength

Bend FittingsSimplex Steels is a prominent Supplier of Stainless Steel Industrial Fittings in Gujarat serving various locations including Ahmadabad, Amreli, Bharuch, Bhavnagar, Bhuj, Dwarka, Gandhinagar, Godhra, Jamnagar, Junagadh, Kandla, Khambhat, Kheda, Mahesana, Morbi, Nadiad, Navsari, Okha, Palanpur, Patan, Porbandar, Rajkot, Surat, Surendranagar, Valsad, Veraval and etc.We are engaged in manufacturing, supplying and exporting a wide range of industrial fittings. If you are interested in our products feel free to contact us via call or email.

Read the full article

#Ahmedabad#Amreli#Banjofittings#Bharuch#coupling#Elbowfittings#Gujarat#India#Patan#Pipenipple#Pipesfittings#Rajkot#Reducers#Reusablefittings#SimplexSteel#StainlessSteelIndustrialFittings#Tubefittings#Washers

0 notes

Text

Mastering the Art of Fixing a Dripping Faucet: Your Ultimate Guide

When it comes to dealing with the pesky nuisance of a dripping faucet, we understand your frustration. That incessant, rhythmic drip not only wastes precious water but can also disrupt your peace of mind. In this comprehensive guide, we, the experts in plumbing and household maintenance, will empower you with the knowledge and skills to fix that dripping faucet like a pro.

The Irritating Symphony of a Dripping Faucet

A dripping faucet is not just a minor annoyance; it's a hidden source of water wastage that can significantly impact your utility bills and the environment. According to the Environmental Protection Agency (EPA), a single faucet dripping at a rate of one drop per second can waste over 3,000 gallons of water in a year! Moreover, the incessant sound can lead to sleepless nights and frayed nerves.

Tools of the Trade

Before we delve into the step-by-step process of fixing your dripping faucet, let's gather the essential tools and materials you'll need for this DIY plumbing endeavor. Having the right equipment on hand will make the task smoother and more efficient.

1. Adjustable Wrench

An adjustable wrench is your trusty companion for loosening and tightening various faucet components.

2. Replacement Parts

Depending on your faucet type, you may need replacement parts such as O-rings, washers, or cartridges. Make sure to identify your faucet model and purchase the necessary components.

3. Screwdrivers

Both flathead and Phillips screwdrivers are essential for removing screws and accessing hidden parts within the faucet.

4. Plumber's Tape

Also known as Teflon tape, plumber's tape is crucial for preventing leaks in threaded connections.

5. Bucket and Towels

Be prepared for some water spillage by having a bucket and towels nearby to catch and clean up any mess.

Identifying the Culprit

Understanding the anatomy of your faucet is the first step in resolving the issue. While there are various faucet types, most dripping faucets can be attributed to one of the following common culprits:

1. Worn-Out O-Rings

O-rings are small rubber gaskets that create a watertight seal within the faucet. Over time, they can deteriorate, leading to leaks.

2. Damaged Washers

Washers, located in the faucet handles, can wear down or become damaged, resulting in a constant drip.

3. Faulty Cartridge

Cartridges control the flow of water in modern faucets. If the cartridge is defective, it can cause leakage.

4. Corroded Valve Seat

A valve seat is the connection between the faucet and the spout. Corrosion in this area can lead to leaks.

The Fixing Process

Now that we've identified potential issues, it's time to roll up our sleeves and get to work. Follow these steps diligently to fix your dripping faucet:

Step 1: Turn Off the Water Supply

Before you begin, ensure that the water supply to the faucet is completely shut off. Look for shut-off valves under the sink or at the main water supply.

Step 2: Dismantle the Faucet

Using your adjustable wrench and screwdrivers, carefully dismantle the faucet. Be sure to keep track of the removed parts and their order to facilitate reassembly.

Step 3: Inspect and Replace Components

Examine the O-rings, washers, cartridge, and valve seat for signs of wear, damage, or corrosion. Replace any faulty components with the new ones you've gathered.

Step 4: Reassemble the Faucet

Reassemble the faucet in the reverse order of disassembly. Ensure that all parts fit snugly and securely.

Step 5: Turn On the Water Supply

Once the faucet is reassembled, slowly turn on the water supply to check for leaks. If there are no leaks, congratulations! You've successfully fixed your dripping faucet.

Preventative Maintenance

To avoid future faucet troubles, consider implementing regular preventative maintenance:

Periodically clean and lubricate the faucet to prevent mineral buildup.

Check for and address leaks promptly to prevent further damage.

Install water-saving aerators to reduce water wastage and save on utility bills.

By mastering these simple techniques, you can keep your faucets in optimal condition and enjoy a drip-free, peaceful home.

Conclusion

In this comprehensive guide, we've equipped you with the knowledge and skills to conquer the annoyance of a dripping faucet. By identifying the root causes and following our step-by-step fixing process, you can save water, money, and your sanity.

Looking for more tips on bathroom maintenance and fixtures? Check out these informative articles on BlissfulBathroom:

Easy Ways to Fix a Dripping Faucet: Dive deeper into faucet troubleshooting and repair techniques.

Is Your Bathroom Vanity High Quality?: Learn how to assess the quality of your bathroom vanity and make informed choices during renovations.

How to Clean Bathroom Taps: A Step-by-Step Guide: Discover a thorough guide to keeping your bathroom taps sparkling and functional.

Are Faucet Cartridges Universal?: Gain insights into faucet cartridges and whether they are interchangeable across different brands.

So, don't let that pesky drip continue to torment you. Take control and become a DIY plumbing pro. Fixing a dripping faucet is not just a household chore; it's a step towards a more sustainable and tranquil living environment.

A well-maintained faucet is a happy faucet.

#fix dripping faucet#how to fix dripping faucet#Dripping Faucet#Faucet Repair#Plumbing Tips#DIY Plumbing#Household Maintenance#Water Conservation#Faucet Components#O-Rings#Washers#Cartridge Replacement#Valve Seat#Preventative Maintenance#Bathroom Fixtures#Home Improvement#Sustainable Living#Water Efficiency#Home DIY#Plumbing Guide#Water Leak#Faucet Troubleshooting#Home Plumbing#Fixing Faucet Leaks#Faucet Maintenance#Plumbing DIY#Water-Saving Tips#Faucet Types#Home Repair#Water Waste

0 notes

Text

Top Quality Washers Manufacturer in India - Ananka Group

Ananka Group is the high-quality Washers Manufacturer in India. We stock a large variety of washers that are available for supply and export. Since we are India's leading manufacturer of specialised washers, we also accept orders tailored to the needs of our clients.

We are India's largest manufacturer of larger diameter washers, bolts, and fasteners made of high-tensile and stainless steel grades. Our clients are large contractors and consultants working on projects in the country's infrastructure, wind, and power sectors. We also specialise in stainless steel Bolts, Nuts, and other fasteners.

There are different types of washers, ranging from split lock washers to flat washers and spring washers, each with a unique function. Split lock washers add a tension similar to a spring to keep the washer from loosening, while flat washers are simple and offer a smooth surface to distribute loads. Although they are made in a way that permits some flexibility, spring washers also provide tension. Also, we are a Leading Fasteners Manufacturer in India

For more details:

Product Source:

Washers Supplier in India

0 notes

Text

Carbon Steel Square Washers With Round Holes

Finish: ZINC

Style: Square washer

Material: Carbon steel

Application: General Industry

1 note

·

View note

Text

What Is the Manufacturing Method Of The Washer?

Washers are flat and small metal discs that have holes in their center. These accessories are essential for distributing load from the fasteners like bolts, screws, or threaded fasteners.

These fastening accessories find applications in manufacturing, construction, and more. These accessories provide better fastening. Washers available at reputed fastener manufacturers in India like Fasteners & Fixtures LLP utilize advanced manufacturing

processes, guaranteeing high quality. The following article explains washer manufacturing and the processes involved.

Washer: Definition

A washer is a perforated disc or plate made of metals of different types. These accessories are placed between the fastener surfaces like nuts and bolts. The washers are subject to rotary

force. One more example can be screw and bolt fitting. A washer is perfect to close the gap between the threaded fasteners.

Metal washer: Manufacturing processes

Washers undergo multiple manufacturing processes like stamping, cutting, machining, and more. They utilize metal sheets for manufacturing and have a hole punched in the middle. Washers are available in flat, spring, or lock washers. Each fastener provides features like lock ability, spring tension, or load distribution.

Washers utilize manufacturing techniques like stamping, waterjet cutting, machining, laser cutting, etc. Stamping is one of the common manufacturing processes of washers. It involves

passing a flat metal sheet in a stamping press, which can cut and shape the washers per their design requirements. Another process in washer manufacturing is machining, which requires a lathe machine or milling machine for material removal. The raw material in the form of a metal rod or bar is fitted in the lathe and undergoes material removal, offering it the desired shape and dimension. Washers can also be made using laser or waterjet cutting. These are advanced

manufacturing techniques utilizing laser beams or water pressure for cutting the metal in the desired shape of the washers.

Steps in washer manufacturing

Washers are available in multiple material options, like copper, aluminum, stainless steel, and carbon steel. The choice of the washer is dependent on its application. For instance, stamping is the top choice in washer manufacturing. This process utilizes a die made for designing washers and their thickness can be determined with gauge. Following are the steps involved in washer manufacturing using mental stamping:

Washer manufacturing using stamping requires a power press. It also involves using a

die that gives the washer its shape during stamping.

A metal disc is placed in the press, which undergoes punching in the die. The bolster

plate undergoes punching, giving the desirable shape using the downward motion from the ram, producing washers in desirable shapes, also called blanks.

The die used on these metals is a custom washer die for manufacturing a washer from a metal sheet. One sheet of metal can produce many washers as they are really small.

After punching the washers from the metal sheet, a gauge is utilized to determine the washer thickness, ultimately deciding its spacing.

Metals for manufacturing washers Washers can be manufactured from stainless steel, copper, brass, aluminum, and carbon steel.

Stainless steel is the top choice for manufacturing stainless steel 304 fasteners like washers as the material has high durability and strength. S.S. washers offer properties like corrosion resistance, making them perfect for corrosive environments. Copper and brass washers are another washer type suitable for applications like electrical and plumbing as they have high conductivity. Aluminum washers on the other hand have low weight and find applications requiring low system weight. The washer material choice is dependent on the desirable properties and application.

Final thoughts

Washers offer an extensive range of benefits. They are strong and durable and help distribute the load on fasteners. These fasteners also allow reuse, making them sustainable. If you are looking for a reputed fastener manufacturer for sourcing washers for your project, consult experts at the leading fastener manufacturer Fasteners and Fixtures LLP.

0 notes

Text

We are one of the leading company in the various fields in Maharashtra, Specialized in Operating & Maintaining Fire Fighting System, Plumbing System, Drip, Sprinkler Irrigation system work at Private & Government Establishments, and also engaged in Dewatering Pumps Providing on Rental Basis.

1 note

·

View note