#laser prints

Text

{2024} Geschichte

#gif#animation#anna malina#art#artists on tumblr#black and white#paper collage#collage animation#found footage#soviet cinema#2024#landscapes#houses#laser prints

487 notes

·

View notes

Photo

©Philomena Famulok

2022

#Philomena Famulok#personal#mixed media#mixed techniques#Instant Film#instant camera#double exposure#analog photography#laser prints#scanner#Forest#trees#emotion#my photography

2K notes

·

View notes

Text

So I’ve held this close to my chest in case it went horribly wrong, but I love working in a place full of scientists, engineers and general tech enthusiasts because it means when I came across someone’s open source 3D printed and laser cut design for a 4-shaft loom, there were plenty of enthusiasts ready to help make it a reality.

I’ve had great fun over my birthday weekend putting together the bits I’ve gotten so far (only missing the dowling that I’ve ordered and the flexible tpu parts -the heddles)

She also glows in the dark and folds!! you can see the back two arms in the folded position and all the 3D printed parts were made of glowwy filament, which is my favourite thing ever, as an added treat 🌖

There’s still some hiccups to address, such as no assembly instructions, everything (including the screw paths) being mirrored from one side to the next (plus ratchets on BOTH sides??) and I definitely have not quite worked out the how the folding mechanism/lock functions (and I’ve put my reeds on back to front 🤦🏻) but those are all problems for when I’ve got the rods and cut them to size and it starts to feel like a functioning object!!!

#cotton khaleesi#cottonkhaleesi#loom weaving#weaving#4-shaft weaving loom#3d printing#laser cutting#open source

59 notes

·

View notes

Text

1996 Pioneer Anime Magazine Ad featuring Tenchi Muyo! Ryo-Ohki

#pioneer#pioneer lcd#anime#90s#1990s#90s anime#tenchi muyo#tenchi muyo!#tenchi muyo ryo ohki#laser disc#vhs#1996#el-hazard#the hakkenden#armitage iii#print ads#magazine ads

125 notes

·

View notes

Text

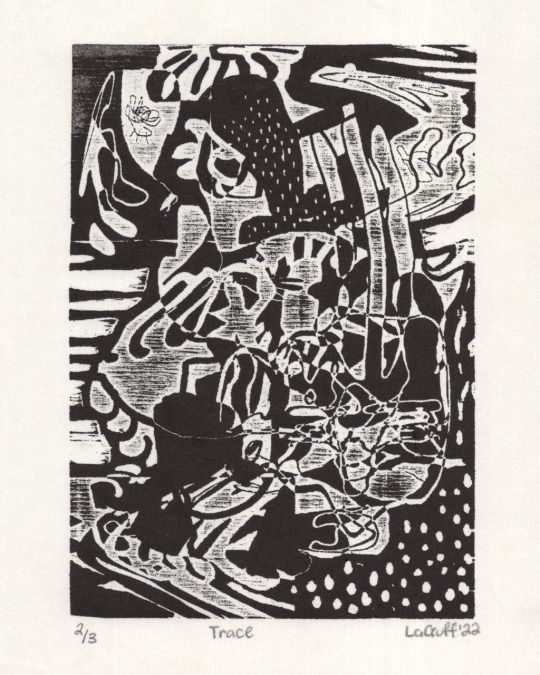

Trace

22.86 x 17.78 cm

Laser Engraved Woodcut

2022

12 notes

·

View notes

Text

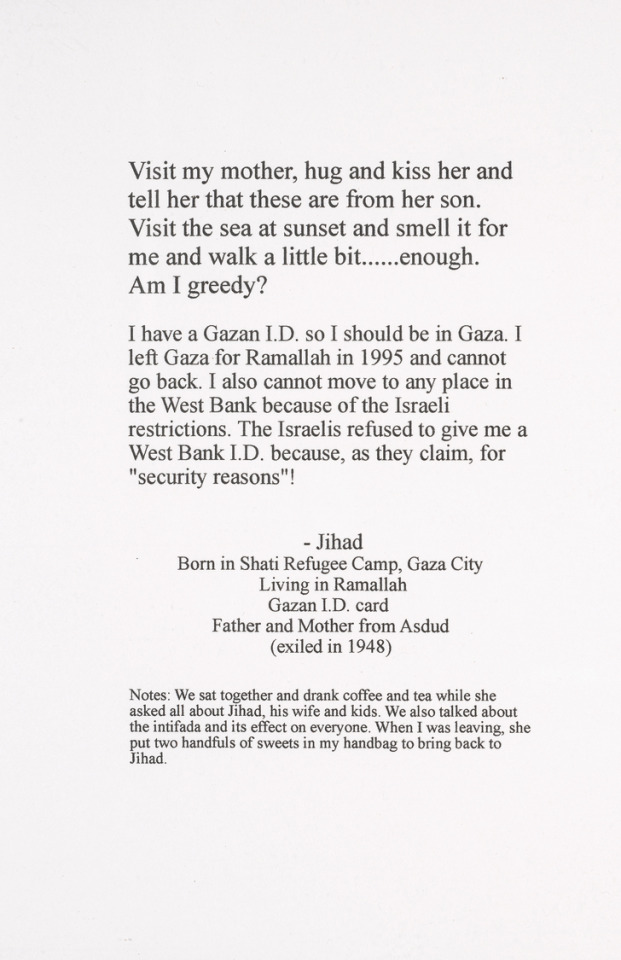

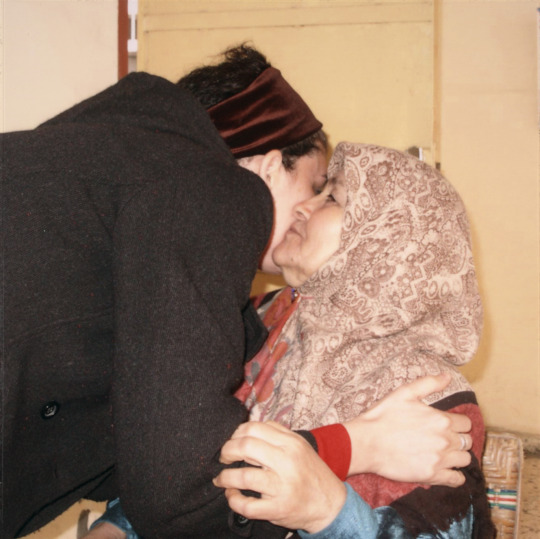

Emily Jacir, Where We Come From (Jihad), (chromogenic print and laser print mounted on board), 2001-2003 [SFMOMA, San Francisco, CA. © Emily Jacir]

14 notes

·

View notes

Text

Thank you for the email, Reddit.

Me too.

201 notes

·

View notes

Text

Researchers from EPFL have resolved a long-standing debate surrounding laser additive manufacturing processes with a pioneering approach to defect detection.

The progression of laser additive manufacturing -- which involves 3D printing of metallic objects using powders and lasers -- has often been hindered by unexpected defects. Traditional monitoring methods, such as thermal imaging and machine learning algorithms, have shown significant limitations. They often either overlook defects or misinterpret them, making precision manufacturing elusive and barring the technique from essential industries like aeronautics and automotive manufacturing. But what if it were possible to detect defects in real time based on the differences in the sound the printer makes during a flawless print and one with irregularities? Up until now, the prospect of detecting these defects this way was deemed unreliable. However, researchers at the Laboratory of Thermomechanical Metallurgy (LMTM) at EPFL's School of Engineering have successfully challenged this assumption.

Read more.

#Materials Science#Science#Additive manufacturing#Defects#Lasers#3D printing#Acoustics#Powder bed fusion

18 notes

·

View notes

Photo

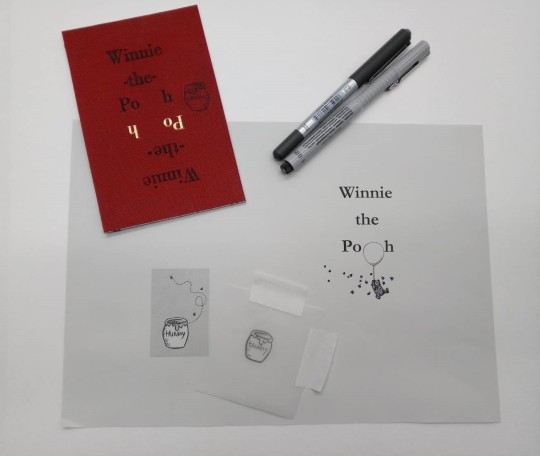

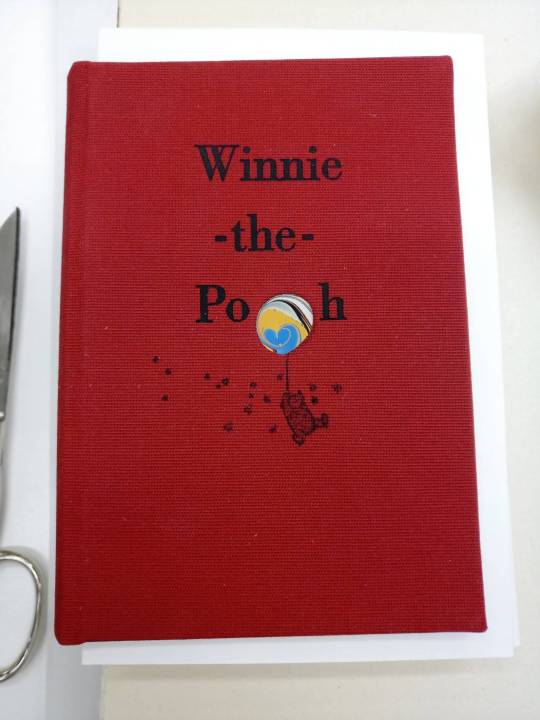

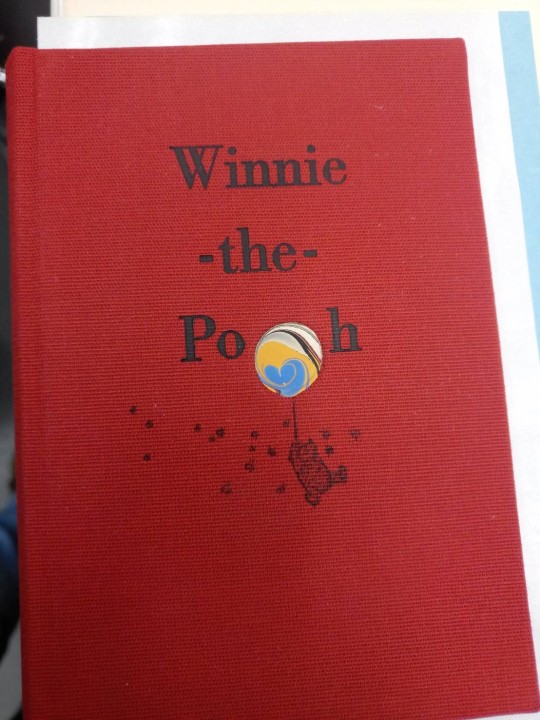

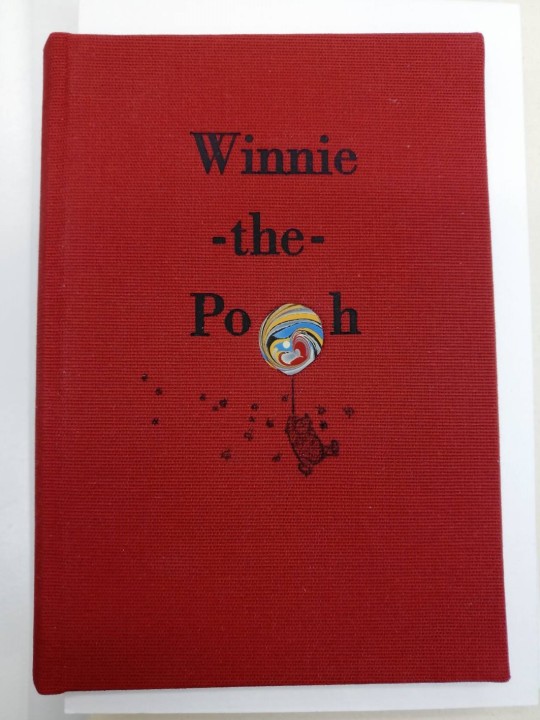

WIP Winnie-the-Pooh

Part VI

decorating and titling the case

This cover is a mess of different decoration techniques. There is the depression for an inlay, a laser printed picture of Winnie, the honey pot on the back side is painted on and finally the title was hot stamped.

As a last touch I added the inlay for the balloon and immediately messed up because I cut the marbled paper too small and it looked more egg-like.

So I went fixing it...

Which gave me a differently shaped egg with paper running up the edge of the set back area -_-

So I kept fixing and now it looks pretty balloon-shaped.

If nothing else worked I was prepared to add another, better cut piece of paper. But I liked the little heart in the other cut out, so I really wanted that to work.

#bookbinding#wip winnie the pooh#decorating the cover#titling#paper inlay#laser printed cover#painted cover#hot stamping

31 notes

·

View notes

Text

Tested my screens they work very good excited to slap these on stuff and make more designs.

(Underglaze on rice paper)

#ladybug could be better but its still cute#i might also burn these on some wood bc i can use the laser printer too. next thing im going to be shown is 3d modeling#and the 3d printers#but i dont rlly have much need for 3d printing and like random plastic stuff so idk if id use it much but its fun to learn

17 notes

·

View notes

Text

{2023} Kollaps

#gif#anna malina#animation#art#artists on tumblr#black and white#paper collage#collage animation#multiple panels#laser prints#2023

1K notes

·

View notes

Photo

©Philomena Famulok

mixed media, 2022

#Philomena Famulok#personal#mixed media#analog collage#collage on paper#own photo snippets#scissor#scan#laser prints#my photography

1K notes

·

View notes

Text

Finally at a stage of actually trialling out this loom (despite all my weaving accoutrements being in storage and reverting to a slapdash cereal box shuttle)! It has a few niggles; namely that the designer clearly doesn’t weave herself, thus didn’t know the practical differences between a 4-shaft and rigid heddle loom, just the cosmetic ones. But unexpected side effect I do love: being able to balance my laptop on top of the whole thing because the shaft controls are on the sides! Wooo!

It works!! Look at that beautiful zigzag pattern.

#cotton khaleesi#cottonkhaleesi#weaving#4-shaft loom#4 shaft loom#the loom that sca built#3D printing#laser cutting

23 notes

·

View notes

Text

Guilty Gear

#textpost#Thinking about how excited I am for that 3D printer to come in#So I can go insane for a few months and put way too much money and effort into#printing a 4ft long 20lb? scifi-fantasy laser fire gun sword with a belt on it#I typed up a whole thing but deleted it because leaving it at Guilty Gear with the puppy pic is funnier

30 notes

·

View notes

Text

as an extension of the halloween costume redesign post i made Once Upon a Time ™️ (not that long ago): jeremy's cyborg eye thing being made of a partial face mask like the phantom of the opera. yes as a reference to his theatre geek side & once again alluding to his connection with christine. (as mentioned in the tags of my og post)

#the mask is made of a holographic sort of material with circuit prints painted on#and when you take a picture of him in the dark his eye flashes with the red-eye effect.#y'know. like the robot laser... whatever.#hm. actually i like this idea a lot it might be my favorite costume redesign i've come up with#bmc#be more chill#jeremy heere

14 notes

·

View notes

Text

Researchers at the Department of Energy's Oak Ridge National Laboratory have improved flaw detection to increase confidence in metal parts that are 3D-printed using laser powder bed fusion. This type of additive manufacturing offers the energy, aerospace, nuclear and defense industries the ability to create highly specialized parts with complex shapes from a broad range of materials. However, the technology isn't more widely used because it's challenging to check the product thoroughly and accurately; conventional inspection methods may not find flaws embedded deep in the layers of a printed part.

ORNL researchers developed a method that combines inspection of the printed part after it is built with information collected from sensors during the printing process. The combined data then teaches a machine-learning algorithm to identify flaws in the product. Even more significantly, this framework allows operators to know the probability of accurate flaw detection just as reliably as traditional evaluation methods that demand more time and labor.

"We can detect flaw sizes of about half a millimeter -- about the thickness of a business card -- 90% of the time," said ORNL researcher Luke Scime. "We're the first to put a number value on the level of confidence possible for in situ (in process) flaw detection." By extension, that reflects confidence in the product's safety and reliability.

Read more.

#Materials Science#Science#Defects#3D printing#Metals#Additive manufacturing#Powder bed fusion#Lasers#Materials Characterization

10 notes

·

View notes