#electrolysis etching

Text

Did a thing with electrolysis. Tried to purify some platinum and (not that i thought it would work) iridium. It sorta worked. The iron on the precious metals is definitely worn down, but idk what's going on because there wasn't much iron to begin with and not much even degraded, but somehow the solution is now extremely dark green and it turns blue when diluted and the platinum looks etched which i definitely didn't expect to actually happen. Anyway, i'm super confused. Also, this was done in a two-cell system with the anode with the precious metals and the cathode in some salt water (so much salt that it didn't actually dissolve, lol) with a thin bridge built between them and like, somehow the cathode didn't do its job or something because all of the color was near the anode and i couldn't see even any metal hydroxides or metal plated onto the cathode. The cathode side is very basic now, and makes my skin feel pretty slick, so obviously the division did something, but i'm very surprised not even the slightest bit of whatever metals were dissolved in the anode cell was able to get through.

(also, to be clear, it's not like i have a ton of platinum and iridium sitting around in my massive wealth pile, i just have a dozen spark plugs that the local auto shop was throwing away, and they're all platinum/iridium)

#chemistry#electrolysis#experiment#platinum#iridium#metal refining???#due to “bad safety practices” my hand is now stained blue and yellow#yay science

2 notes

·

View notes

Photo

Sikh Kara Two Tone Gold Silver Plated Singh Khalsa Kada Kaur Bangle 5k Kakar BBB

Sikh Kara Two Tone Gold Silver Plated Singh Khalsa Kada Kaur Bangle 5k Kakar

Kara Ref: BBB

Gold and Silver plated Kara with Khanda etched/engraved design available in various sizes. Please choose from Variation list.

Kara size are inner diameter of kara measured in centimetres.

Width of this Kara is approx. 7.5mm and has only Khanda legends etched in the middle edge line in gold colour.

BRAND NEW

Please note there may be some silver/gold plating marks on inner side of kara, this happens in the electrolysis tub and is inevitable and not considered as defect because these always stay in inner side. Attention is paid to keep immaculate look of kara from outside.

P.S. Colour of item may slightly vary due to camera flash and light conditions. Some karas may have negligible small black grinding mark on the kara joint. This is always seen on all karas as most of the Kara making/shaping work is done by hands. However, this do not affect the quality/look of karas.

Please note size may vary plus minus 2mm due to measurement variability between digital calliper and standard ruler. Please note there will be an additional postage charges payable by buyer incase of swap or exchange due to size. Therefore, we request buyer to measure their old kara diameter before choosing size from variations.

Return postage will be paid by the buyer. Any P&p charges paid will be non-refundable.

0 notes

Text

aluminium sheet dealers in Chennai

Aluminum Sheet, Grades and Features

Aluminium sheet or aluminum plate is the result of the process of basic raw aluminum being pressed and rolled into sheets under high pressure. The main reason for using aluminum panels is the combination of lightweight and high strength. Although the strength of aluminum alloys is lower than that of steel, the lightness of the material allows the use of thicker gauges that can compensate for the reduced strength.

There is a process called electrolysis which uses a carbon cathode and anode, alumina is then converted to a liquid state and produces CO2. This liquid aluminum is then cast into various forms to create ingots or sheet plates, which are then used to create aluminum plates and sheets. If you need high standard aluminum sheets, then purchase them from aluminium sheet dealers in Chennai.

Aluminum Sheet Grades and Features

Aluminum foil is widely used in the production of metal insulation jackets. Aluminum is light, flexible, easy to produce on-site, and has good corrosion resistance. In addition, aluminum has many properties so it is often used as an insulating metal. Aluminum sheet types 5052, 6061, and 7075 are used for production. sheet or plate application.

Aluminum sheets or panels can be shaped and welded into simple shapes using the same technology as steel panels. Aluminum has excellent thermal conductivity but is much softer and less strong than stainless steel. Therefore, aluminum pans tend to have thicker walls than carbon or stainless-steel pans. Aluminum is easily machined and can be textured relatively easily by sandblasting and chemical etching.

Why Metal & Alloy Industries

Metal &Alloy Industries is one of the best aluminium sheet dealers in Chennai providing a qualityrange of aluminium sheets or plates of different specifications. Our expertise lies in providing quality aluminum sheets made of quality raw materials.

They are known for their durability, corrosion resistance, rugged construction, and load-carrying properties. Its range is sourced from trusted and certified sources who design these panels and panels according to industry standards and regulations.The company specializes in providing customers with a wide range of Aluminum Sheets in various shapes such as hexagonal, wire, rectangular, flange, valve, coupling, nipple, block, and angle.

0 notes

Text

Elemental Fluorine Market Global Growth and Size Analysis

The elemental fluorine market refers to the industry involved in the production, distribution, and consumption of elemental fluorine, a highly reactive and corrosive chemical element. Elemental fluorine (F2) is a pale yellow, diatomic gas that belongs to the halogen group on the periodic table. It is the most electronegative and reactive of all elements, readily forming compounds with almost all other elements.

Here is some full information about the elemental fluorine market:

Production: Elemental fluorine is primarily produced through the electrolysis of hydrogen fluoride (HF) in a process known as the fluorine production method. HF is reacted with anhydrous hydrogen fluoride to generate fluorine gas. The production process requires specialized equipment and careful handling due to the hazardous nature of fluorine.

Applications: Elemental fluorine finds application in various industries due to its unique properties. Some of the key applications include:

Fluorinated chemicals: Fluorine is used as a reactant in the production of numerous fluorinated compounds, such as fluorocarbons, fluoropolymers, and fluorinated pharmaceuticals.

Electronics and semiconductors: Fluorine-based gases are used in plasma etching processes for semiconductor fabrication.

Pharmaceuticals: Fluorine is often incorporated into drug molecules to enhance their stability, bioavailability, and metabolic resistance.

Uranium enrichment: Elemental fluorine is employed in the isotopic separation of uranium in the nuclear industry.

Rocket propellants: Fluorine-based compounds, such as a mixture of liquid oxygen and fluorine (LOX/F), have been investigated as potential rocket propellants due to their high energy release.

Market Size and Trends: The elemental fluorine market size is influenced by factors such as industrial growth, demand for fluorinated products, and technological advancements. While precise market data may not be available, the global fluorine market was valued at around USD 430 million in 2019, with an anticipated compound annual growth rate (CAGR) of over 5% from 2020 to 2027. The market is expected to witness growth due to the increasing demand for fluorine-based chemicals in various industries, such as automotive, electronics, and pharmaceuticals.

Key Players: Several companies are involved in the production and distribution of elemental fluorine. Some prominent players in the market include:

The Linde Group

Air Products and Chemicals, Inc.

Solvay SA

Navin Fluorine International Ltd.

Kanto Denka Kogyo Co., Ltd.

Pelchem SOC Ltd.

Dongyue Group Ltd.

Safety and Environmental Considerations: Elemental fluorine is highly reactive and poses significant safety challenges. It is toxic, corrosive, and can cause severe burns upon contact with organic materials. Therefore, strict safety measures are necessary during production, transportation, and handling of fluorine gas. Additionally, the environmental impact of elemental fluorine and its derivatives is a concern due to their potential contribution to ozone depletion and global warming. Efforts are being made to develop environmentally friendly alternatives and improve the sustainability of fluorine-related processes.

Please note that market information and trends may vary over time, and it is advisable to consult updated sources and industry reports for the most recent data on the elemental fluorine market.

0 notes

Text

Sulphur Hexafluoride Market Growth, COVID Impact, Trends Analysis Report Forecast to 2033

The market for sulphur hexafluoride is valued at US$ 288.37 million in 2023 and is expected to climb to US$ 487.93 million by 2033. During the projection period, the market will rise at a substantial CAGR of 5.4%. Favorable chemical properties and variegated end-use applications particularly electronic devices continue to supplement the growth of sulphur hexafluoride market.

Sulphur Hexafluoride (SF6) Calibration Gas is manufactured by reaction of fluorine with sulphur through electrolysis. Sulphur hexafluoride has excellent thermal, electrical, and chemical properties which make it suitable for various applications. It is used in industries such as power, medical, electronics, glass, metal, etc.

Sulphur hexafluoride has excellent properties which are compatible with electrical applications. Thermal stability and high dielectric strength of Sulphur hexafluoride provide outstanding cooling and insulating properties. Being an ideal quench, it is used in switchgear and electric circuit breakers.

Sulphur hexafluoride is compatible for high-voltage and medium-high voltage power circuit breakers, electricity sub stations, transformers, high-voltage cables, linear accelerators, electron microscopes, and so on. Use of Sulphur hexafluoride over traditional dielectrics provides certain advantages such as space saving, low weight, and operational safety of the equipment.

In electronics industry, Sulphur hexafluoride is used as an etching gas in the manufacturing of photovoltaic panels, flat panels, and semiconductor devices. Large molecule size and high density of Sulphur hexafluoride make it a preferred etching gas in various electronic production processes.

Get a Sample Copy of the Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-2371

Sustainable Practices Remain Key Agenda of Industry Leaders

Some of the key players featured in this FMI study include, but are not limited to, Advanced Specialty Gases, Air Liquide, Electronic Fluorocarbons, LLC, Axcel Gases, American Gas Products, Solvay S.A., Praxair Technology, Inc., Honeywell International, Fujian Shaowu Yongfei Chemical Co. Ltd., Air Products and Chemicals, Inc., Chengdu Kemeite, Concorde Specialty Gases Inc., and Liming Research Institute.

The global sulphur hexafluoride market is fragmented in nature. Reusing sulphur hexafluoride and incorporating latest technology is the key forte of market leaders. For instance, Solvay reclaims and reuses sulphur hexafluoride gas worldwide to comply with stringent environmental norms. Other players opt for collaborations to strengthen their market presence.

Before Buying, Visit for Customization @ https://www.futuremarketinsights.com/customization-available/rep-gb-2371

Sulphur Hexafluoride Market: Segmentation

The global sulphur hexafluoride market is segmented in detail to cover every aspect of the market and present a complete market intelligence approach to readers.

By Grade

Technical

Electronic

By Application

Electrical Transmission and Distribution

Semiconductor Manufacturing

More about the Report

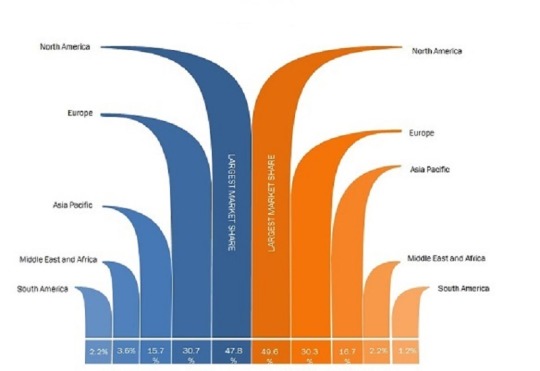

FMI’s study offers an in-depth market forecast and analysis on the global sulphur hexafluoride market. The major categories encompassed by the report include grade, application across five regions (North America, Latin America, Europe, Middle East & Africa, Asia Pacific).

Browse latest Market Reports@

https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

Persulfates Market Size Forecast to Reach $862.83 Million by 2025

Persulfates Market size is forecast to reach $862.83 million by 2025, after growing at a CAGR of 3.40% during 2020-2025. Persulfates are an inorganic compound with more oxygen than normal sulphates. It acts as an oxidizing agent and produced by the electrolysis of a sulfate solution. It is also known as peroxysulfate. It decomposes the material into harmless metal sulfates. Persulfates have many properties like current density, low temperature, strong oxidants with a temperate shelf life using acidic solution owing to oxidation of water. Increasing demand of persulfates in pulp, paper and textiles and the Cosmetics & personal care industry is expected to drive the persulfates market during the forecast period.

Persulfates Market Overview Segment Analysis - By Type

Sodium persulfate segment held a significant share in persulfates market in 2019. Sodium persulfate is a strong oxidizing agent and is used extensively in polymers. Moreover, it is used as an etchant and cleaning agent in PCB manufacturing. It is the second most expensive chemical after ammonium persulfate. The demand for sodium persulfate in cosmetics & personal care end-use industry is projected to grow at the highest rate during the forecast period. On the other hand, ammonium persulfate is a strong oxidizing agent with a slight acrid odor.

Request for Sample of the Report @ https://www.industryarc.com/pdfdownload.php?id=16549

Report Price: $ 4500 (Single User License)

Persulfates Market Overview Segment Analysis - By Application

Bleaching and sizing agent segment held a significant share in persulfates market in 2019. Persulfates are used as bleaching agents in cosmetic & personal care products and in the pulp & and paper and textile industries. Persulfates are used as initiators in the emulsion polymerization reactions for synthesizing polymers of neopropene, polystyrene, acrylics, and polyvinyl chlorides. They are also used as initiators in the production of latex polymers used in applications such as paints, coatings, carpet backing etc. Another most common use of persulfates in the polymer industry is in the manufacturing of synthetic rubbers such as styrene butadiene and isopropene.

Persulfates Market Overview Segment Analysis - By End User Industry

Electronics segment held a significant share in persulfates market in 2019 growing at a CAGR of 3.58% during the forecast period. A persulfate also known as peroxysulfate, is a compound containing the anions of sulfur in normal tetrahedral geometry typical for S(VI) oxidation state. The persulfate salts are strong oxidizers. The growing demand of persulfates in electronics industry owing to usage in cleaning and etching of printed circuit substrates is projected to propel the persulfates market during the forecast period. Persulfates are used for surface cleaning of metals like brass, copper, nickel, aluminum, zinc, and titanium prior to coating, plating and adhesive bonding on electronic components, which is expected to boost the persulfates demand and stimulate its market.

However, with the ongoing COVID-19 outbreak, the end-use industries will be slowing down, except from some applications such as the gloves where latex polymer is used for manufacturing, polymer in food packaging and tissue papers. These slowing down of end-use industries will have an impact on the persulfate demand until 2021. China being the epicenter of COVID-19 has also impacted the persulfates market as more the 70% of the persulfates production capacity is in China.

Persulfates Market Overview Segment Analysis - Geography

Asia Pacific dominated the persulfates market with a share of more than 39%, followed by North America and Europe. In countries like China, India and Japan owing to the increasing demand from various end-user industries such as polymer, electronics, and cosmetics & personal care, the demand for persulfates has been increasing in the region. Growing preference of polymers over metals and rising consumer appliances demand in the region is boosting the polymer initiator sector in the region which is stimulating the persulfates market in the region.

Persulfates Market Drivers

Increasing usage of persulfates in various end user industries

Ammonium persulfate is a strong oxidizing agent with a slight acrid odor. Under the cosmetics & personal care segment, ammonium, potassium, and sodium persulfates are used as oxidizing agents in hair colorants and lighteners. These persulfates are used as preservative agents in food and as initiators in polymerization reactions. They are also useful as boosters in the stimulation of oil & gas wells. In electronics, persulfates act as etching agents for zinc and Printed circuit boards. They are also used as bleaching agents in cosmetic & personal care products and in the pulp & and paper and textile industries. Ammonium persulfate is used as a component of paper and paperboard in contact with aqueous, fatty, and dry foods and in cellophane films. Persulfates are also used for oxidative degradation of toxic substances and chemicals in waste water, which makes the water treatment process easy. Due to this, there is surge in the demand of persulfates for water treatment application.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=16549

Persulfates Market Challenges

Health effects

Allergic reactions, irritations, and rhinitis associated with cosmetic products made from ammonium persulfate are anticipated to restrict the growth of ammonia persulfates to some extent. Precautionary measures are needed to be taken care of during the handling, storage, and disposal of persulfate compounds as they pose health hazards. Issues related to handling, storage, and transportation of persulfates is anticipated to hinder the growth of persulfates to some extent. Persulfates exposure in dust form might cause irritation in throat, lungs, nose eyes and skin. Prolonged exposure may lead to breathing issues leading to asthmatic effects.

Persulfates are slightly irritating to the human skin at higher concentrations. They cause irritation to the human skin and the respiratory tract of occupationally exposed individuals. Therefore, their usage is regulated in developed countries such as the U.S. The toxicity of potassium persulfates is mild, but continuous exposure to them can cause negative effects on human health. The adverse effects caused by exposure to potassium persulfates include cancer, issues related to one’s reproductive systems, etc. Sodium sulfate is a well-known substitute for potassium persulfate in few analytical processes due to the similar qualities that are seen in both compounds.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the persulfates market. In 2019, the market of persulfates has been consolidated by the top five players accounting for xx% of the share. Major players in the persulfates market are PeroxyChem, United Initiators, Mitsubishi Gas Chemical Company, Ak-Kim Kimya, Adeka Corporation and Fujian Zhanhua Chemical Company among others.

Geographical Expansion/ Acquisition

In 2020, Evonik has acquired PeroxyChem, which is a manufacturer of hydrogen peroxide, peracetic acid and persulfates for USD 625 million.

In 2019, United Initiators opened a new plant with 10 KT annual production capacity of sodium persulfates in Huaibei, China.

In 2018, United Initiators entered into a joint venture with VR Persulfates from India for the manufacturing of persulfates.

In 2017, PeroxyChem launched the Klozur series of sodium persulfate, as it is expected to be advantageous for use in-situ chemical oxidation (ISCO).

Key Takeaways

Growing application of persulfates in cosmetics & personal care industry and rising demand of soil remediation techniques are expected to offer various lucrative opportunities for the growth of market.

By end user industry, electronics segment is expected to dominate the market owing to the increase in the usage of persulfates in printed circuit boards to remove moisture.

Asia Pacific dominated the persulfates market.

Related Reports :

A. Ammonium Sulfate Market

https://www.industryarc.com/Report/15396/ammonium-sulfate-market.html

B. Ferric Sulfate Market

https://www.industryarc.com/Report/15853/ferric-sulfate-market.html

About IndustryARC: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications market research. Our Custom Research Services are designed to provide insights on the constant flux in the global supply-demand gap of markets. Our strong team of analysts enables us to meet the client research needs at a rapid speed, with a variety of options for your business. Any other custom requirements can be discussed with our team, drop an e-mail to [email protected] to discuss more about our consulting services.

0 notes

Text

Caustic Soda Flakes Vs. Caustic Soda Granules (Pearls): Key Differences

You might be a bit confused with different forms of caustic soda. Which one is best suited for your use? There must be some reasons behind their different names and categories. So, learning about it from the caustic soda manufacturers is always a smart move from your side.

The caustic soda is noted to be sodium hydroxide, which is also called lye. All the different forms of it are the same exact thing, but with some different names to them.

The nature of the soda plays a great role while trying to unblock drains and make soap because the caustic will react well with the fat. It will change the composition and help in dissolving fats while making soap consistently.

It is vital for you to understand the reaction that caustic soda presents when it comes in touch with water. The soda is exothermic and will generate heat and let off hydrogen.

So, if you plan to add hot water over here, this process can be a bit dangerous and might cause an explosion. So, it is better to use cold water, even if the process takes a longer time to react.

The Difference in Terms of Physical Appearance and Manufacturing Process:

The physical shape or form of the caustic soda flakes and pearls will have a significant distinction to the theme. The pearls are available in granular form, and the flakes are lamellar. It means that the pearl version will be quite similar to that of fish eggs or caviar. On the other hand, the caustic soda flakes will look like smaller snowflakes.

Even the manufacturing process of the caustic soda flakes and granules will be pretty different.

The caustic soda is mainly produced by following the chloro-alkali technique. It will involve sodium chloride electrolysis in any three types, which are membrane, diaphragm, or mercury.

It can be quite possible to produce around 1.1 tons of caustic soda for every ton of produced chlorine.

On the other hand, you have the technical caustic soda flakes, which are procured by evaporating the liquid version of the caustic soda.

Checking out with the caustic soda suppliers will always be your prime goal whenever you are looking for the best options within flakes and pearls form. Depending on the final reason for which you need caustic soda, the version will vary. Catching up with expert suppliers will solve the purpose as they will get the items delivered right on time.

Uses of Caustic Soda Pearls:

These pearls are mostly used to produce petroleum, paint stripping, soap, and detergent production, to process cotton, and even in aluminum etching. You can even see the use of pearls in the paper industry.

Uses of Caustic Soda Flakes:

The caustic soda flakes are used in alcohol production, cotton making, and leather production, and in the paper production sector. You can even see some of its uses in the soap and detergent production sectors.

So, make sure to focus on the industrial sector first, and then choose the best version between pearls and flakes. Catch up with reputed suppliers for the best results.

0 notes

Text

Plating

There s no such thing as alchemy—magically changing common chemical elements into rare and valuable ones—but water plating is possibly the next best thing. The idea is to use electricity to coat a relatively mundane metal, such as copper, with a thin layer of another, more precious metal, such as gold or silver. Water plating has lots of other uses, besides making cheap metals look expensive. We can use it to make things rust-resistant, for example, to produce a variety of useful alloys like brass and bronze, and even to make plastic look like metal. How does this amazing process work? Let s take a closer look!

Plastic water plating involves passing an electric current through a solution called an electrolyte. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply. The electrodes and electrolyte are made from carefully chosen elements or compounds. When the electricity flows through the circuit they make, the electrolyte splits up and some of the metal atoms it contains are deposited in a thin layer on top of one of the electrodes—it becomes electroplated. All kinds of metals can be plated in this way, including gold, silver, tin, zinc, copper, cadmium, chromium, nickel, platinum, and lead.

Water plating is very similar to electrolysis (using electricity to split up a chemical solution), which is the reverse of the process by which batteries produce electric currents. All these things are examples of electrochemistry: chemical reactions caused by or producing electricity that give scientifically or industrially useful plastic water plating products.

How does water plating work?

First, you have to choose the right electrodes and electrolyte by figuring out the chemical reaction or reactions you want to happen when the electric current is switched on. The metal atoms that plate your object come from out of the electrolyte, so if you want to copper plate something you need an electrolyte made from a solution of a copper salt, while for gold plating you need a gold-based electrolyte—and so on.

Next, you have to ensure the electronic products shell plastic water plating you want to plate is completely clean. Otherwise, when metal atoms from the electrolyte are deposited onto it, they won t form a good bond and they may simply rub off again. Generally, cleaning is done by dipping the electrode into a strong acid or alkaline solution or by (briefly) connecting the Water plating circuit in reverse. If the electrode is really clean, atoms from the two-color material plating bond to it effectively by joining very strongly onto the outside edges of its crystalline structure.

Now we re ready for the main part of two-color material twice molding water plating. We need two electrodes made from different conducting materials, an electrolyte, and an electricity supply. Generally, one of the electrodes is made from the metal we re trying to plate and the electrolyte is a solution of a salt of the same metal. So, for example, if we re copper plating some brass, we need a copper electrode, a brass electrode, and a solution of a copper-based compound such as copper sulfate solution. Metals such as gold and silver don t easily dissolve so have to be made into solutions using strong and dangerously unpleasant cyanide-based chemicals. The electrode that will be plated is generally made from a cheaper metal or a nonmetal coated with a conducting material such as graphite. Either way, it has to conduct electricity or no electric current will flow and no plating will occur.

How are plastics electroplated?

If you know anything about plastic, you ll spot the obvious problem straightaway: plastic product molding generally don t conduct electricity. In theory, that should completely rule out electroplating; in practice, it simply means we have to give our plastic an extra treatment to make it electrically conducting before we start. There are several different steps involved. First, the plastic surface treatment has to be scrupulously cleaned to remove things like dust, dirt, grease, and surface marks. Next, it s etched with acid and treated with a catalyst (a chemical reaction accelerator) to make sure that a coating will stick to its surface. Then it s dipped in a bath of copper or nickel (copper is more common) to give it a very thin coating of electrically conducting metal (less than a micron, 1μm, or one thousandth of a millimeter thick). Once that s done, it can be electroplated just like a metal. Depending on how much wear and tear the plated part has to withstand, the coating can be anything from about 10–30 microns thick.

0 notes

Photo

Gurmukhi Alphabet Kara Silver Plated Sant Bhindranwale Words Sikh bangle N13 Sant Bhindranwale Kara Gurmukhi Kada Antique Silver Plated Sikh Singh Bangle Design No. N13BRAND NEW and in sealed bagsWidth: approx. 7mmThickness from Inner side to the edge/collar approx. 5mmWeight approx. 12-26gSizes of Kara are Inner diameter. Please choose correct size from Variation list.If you are not sure of size then please message us and we will send you guidance photos to help you find your Kara size.Sizes:

XXSmall 2/4 or 5.4cm

XSmall 2/6 or 5.7cm

Small 2/8 or 6.0cmMedium 2/10 or 6.3cmMedium 2/12 or 6.7cmLarge 2/14 or 7.0cmXLarge 2/16 or 7.3cm

One side of these kara are engraved/etched with Gurmukhi Alphabet (Punjabi Painiti)ੳ Ura ਅ Era ੲ Iri ਸ Sussa Sa ਹ Haha Ha ਕ Kukka Ka ਖ Khukha Kha ਗ Gugga Ga ਘ Ghugga Gha ਙ Ungga Nga ਚ Chucha Ca ਛ Chhuchha Cha ਜ Jujja Ja ਝ Jhujja Jha ਞ Yanza Nya ਟ Tainka Tta ਠ Thutha Ttha ਡ Dudda Dda ਢ Dhudda Ddha ਣ Nahnha Nna ਤ Tutta Ta ਥ Thutha Tha ਦ Duda Da ਧ Dhuda Dha ਨ Nunna Na ਪ Puppa Pa ਫ Phupha Pha ਬ Bubba Ba ਭ Bhubba Bha ਮ Mumma Ma ਯ Yaiyya Ya ਰ Rara Ra ਲ Lulla La ਵ Vava Va ੜ Rahrha R

Other side of this Kara there's wording of Sant Jarnail Singh Bhindranwale:ਮੈਂ ਸਰੀਰ ਦੇ ਮਰਨ ਨੂੰ ਮੌਤ ਨਹੀਂ ਗਿਣਦਾ, ਜ਼ਮੀਰ ਦੇ ਮਰਨ ਨੂੰ ਮੌਤ ਗਿਣਦਾ ਹਾਂ - ਸੰਤ ਜਰਨੈਲ ਸਿੰਘ ਜੀ ਖਾਲਸਾ ਭਿੰਡਰਾਂਵਾਲੇMeaning in English: ‘Physical Death I Do Not Fear, The Death Of Conscience Is A Sure Death.’ - Sant Jarnail Singh Ji Khalsa Bhindranwale

Please note there may be a slight scratch or a mark present on inner side of Kara. This is usual and it happens during the engraving of Kara on Machine or sometimes due to thread, with which these hang in electrolysis bucket during plating process.

These Kara designs are launched recently and are very popular in market right now - very famous in youngsters and we are the only seller who has this exclusive for sale in UK

Please choose variation size while buying or mention it to us in your note:

Please read below more Information about Sikh Kara:A kara ਕੜਾ کڑا कड़ा KADA, is a steel or iron (sarb loh) Bracelet, worn by all initiated Sikhs. It is one of the five kakars or 5Ks — external articles of faith — that identify a Sikh as dedicated to their religious order. The kara was instituted by the tenth Sikh Guru Gobind singh at the Baisakhi Amrit Sanskarn in 1699. Guru Gobind Singh Ji explained:He does not recognise anyone else except me, not even the bestowal of charities, performance of merciful acts, austerities and restraint on pilgrim-stations; the perfect light of the Lord illuminates his heart, then consider him as the immaculate Khalsa.The kara is to constantly remind the Sikh disciple to do God's work, a constant reminder of the Sikh's mission on this earth and that he or she must carry out righteous and true deeds and actions, keeping with the advice given by the Guru. The Kara is a symbol of unbreakable attachment and commitment to God. It is in the shape of a circle which has no beginning and no end, like the eternal nature of God. It is also a symbol of the Sikh brotherhood. As the Sikhs' holy text, the Guru Granth Sahib Ji says, "In the tenth month, you were made into a human being, O my merchant friend, and you were given your allotted time to perform good deeds." Similarly, Bhagat Kabir reminds the Sikh to always keep one's consciousness with God: "With your hands and feet, do all your work, but let your consciousness remain with the Immaculate Lord."The basic kara is a simple unadorned steel bracelet, but other forms exist. It was historically used like a Knuckle-duster for hand-to-hand combat. Battlefield variations include kara with spikes or sharp edges. Sikh soldiers of the British Indian army would settle disputes by competing in a form of boxing known as loh-musti (lit. iron fist) with a kara on one hand.

Free Royal Mail Postage in UK.

Postage discounts will be given to International buyers for multi-buys.

Any questions please do not hesitate to contact us.

P.S. Colour of item may slightly vary due to camera flash and light conditions. Some kara may have negligible small black grinding mark on the kara joint. This is always seen on all kara as most of the Kara making/shaping work is done by hands. However, this do not affect the quality/look of kara.

https://www.ebay.co.uk/itm/Gurmukhi-Alphabet-Kara-Silver-Plated-Sant-Bhindranwale-Words-Sikh-bangle-N13-/285353708981

0 notes

Text

potassium hydroxide solution

What is Potassium hydroxide solution?

KOH aqueous (potassium hydroxide solution) is a colorless inorganic liquid that functions as a strong base (alkali). KOH solution, commonly known as caustic potash or potash lye, is used in a variety of ways. Chlorine and hydrogen are created as co-products of the KOH liquid manufacturing process.

Uses of Potassium Hydroxide solution

Potassium hydroxide solution is used in a variety of industries, including food, personal care, and pharmaceuticals, as well as agricultural and glass making. It's also utilized as an electrolyte in the creation of alkaline batteries, biodiesel, and runway deicers.

Caustic potash is also used in the production of liquid fertiliser combinations due to its low salt index and high solubility. KOH liquid has been shown to boost agricultural output and improve drought tolerance. KOH lye is also used as an intermediary in the production of personal care products such as liquid lotions, soaps, and shampoos. It reacts with grease and fats as a strong base, making it an effective ingredient in drain and oven cleansers as well as non-phosphate detergents.

It also contributes to human health. It is widely accepted in the wet mount preparation of various clinical specimens for microscopic visualization of fungi and fungal components in the skin, hair, nails, and other body tissues. Its efficacy and tolerability in the treatment of warts has recently been investigated. A topical KOH solution was discovered to be a safe and efficient treatment for plane warts.

How to get it?

Historically, KOH was made by adding potassium carbonate to a strong solution of calcium hydroxide (slaked lime) The salt metathesis reaction results in precipitation of solid calcium carbonate, leaving potassium hydroxide in solution:

Filtering off the precipitated calcium carbonate and boiling down the solution gives potassium hydroxide ("calcinated or caustic potash"). This method of producing potassium hydroxide remained dominant until the late 19th century, when it was largely replaced by the current method of electrolysis of potassium chloride solutions.The method is analogous to the manufacture of sodium hydroxide.

Hydrogen gas forms as a byproduct on the cathode; concurrently, an anodic oxidation of the chloride ion takes place, forming chlorine gas as a byproduct. Separation of the anodic and cathodic spaces in the electrolysis cell is essential for this process.

How to store potassium hydroxide?

Because potassium hydroxide absorbs a lot of moisture from the air, it needs to be kept in a cold, dry environment. To avoid inhalation difficulties, we recommend storing chemicals in a firmly closed chemical storage tank in a well-ventilated environment.

It should be stored potassium hydroxide solutions in plastic bottles (polyethylene or polypropylene). Glass may be etched using KOH solutions in just a few days. Caustic potash must be contained in a double-walled containment system due to its dangerous and highly corrosive nature. Another form of storage system is a "tank inside a tank," which provides additional safety by providing entirely enclosed secondary containment. The safe tank has the same footprint as a vertical storage tank and provides 110 percent containment, making it simple to store the chemical wherever it is most efficient and convenient.

0 notes

Text

Etching process enhances the extraction of hydrogen during water electrolysis

https://koliasa.com/etching-process-enhances-the-extraction-of-hydrogen-during-water-electrolysis/

Etching process enhances the extraction of hydrogen during water electrolysis - https://koliasa.com/etching-process-enhances-the-extraction-of-hydrogen-during-water-electrolysis/ ...

0 notes

Photo

What is a watering can rose gold? There are many styles of color plated rose gold watering cans on the market, the most commonly used is stainless steel plated rose gold with gold.

Stainless steel rose gold is an alloy of gold and copper, with a very stylish and beautiful rose red color sense. How is mirror rose gold a rose gold watering can make by master craftsmanship?

Stainless steel rose gold watering cans are commonly available in rose gold and red gold finishes in 201, 304, and 316 materials respectively.

Usually, 304 stainless steel can be used for high-carbonate rose gold watering cans. The thickness of the internal structure used for fabrication is usually 1.0mm and the thickness of the external structure is usually 1.2-5mm.

The general surface techniques for rose gold watering cans are brushed, mirror, satin, snowflake sand, 8k mirror, sandblasted, etc.

Multiple processes can also be processed in combination to form beautiful lines. The surface of stainless steel is easy to produce fingerprints, you can spray anti-fingerprint oil on the finished rose gold watering cans for more vivid color and superior corrosion resistance.

1. SURFACE TREATMENT

Before color plating, the watering can need to be treated with the polishing process. Then the rest of it is laser welded and polished, and finally vacuum plated and colored.

2. HOW MANY KINDS OF SURFACE TREATMENTS ARE AVAILABLE

While in the industry we also become the metal surface treatment, we have about the following common treatments.

Electroplating, etching, polishing, sandblasting, metal brushing, anodizing, electrophoresis, PVD vacuum plating, powder coating, micro-arc oxidation, etc.

And daily contact with suppliers, we hear the most when the plating process is none other than.

3. HOW ELECTROPLATING COLORING WORKS

Electroplating is the use of electrolysis to make the metal surface coated with a metal film process so as to prevent corrosion, improve wear resistance, electrical conductivity, reflectivity, and most importantly, increase the appearance.

We see daily on the stainless steel products rose gold, titanium gold, ruby blue, and so on various shades, theoretically, the plating can help you plating out the desired color.

RunSun Houseware design

As a global leader in Houseware, RunSun provides more than 2500 Houseware designs for Europe, America, and Australia.

Contact RunSun

Email: [email protected]

WeChat/Whatsapp: (+86)13246751686

Phone: +86 13246751686

Website:https://www.runsun-trans.com/

0 notes

Text

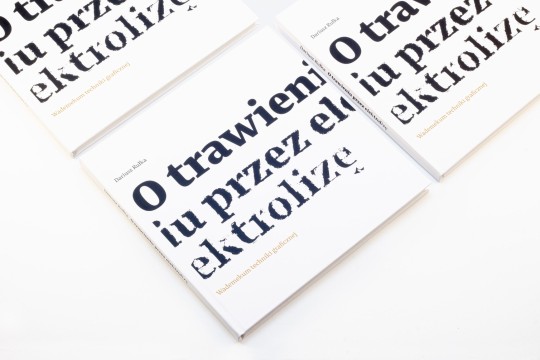

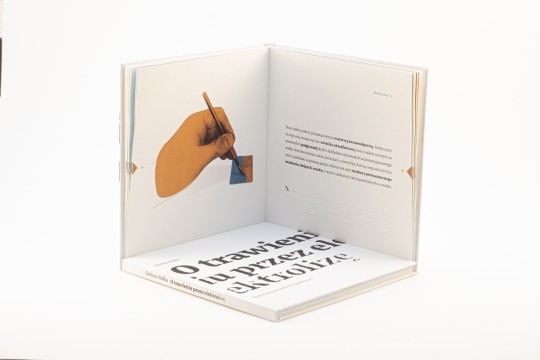

Etching by electrolysis

O trawieniu przez elektrolizę

0 notes

Photo

Trabajando en unas cosas ochenteras hoy, entre el trazado del emblema de Cobra Kai y algunos Pokemon, para nuevos encargos grabados en acero quirúrgico. Working on some eighties stuff today, between tracing the Cobra Kai emblem and some Pokemon, for new assignments etched into surgical steel. quirúrgico#concepts #wip #desing #diseño #vector #plate #placa #aceroinox #inoxsteel #surgicalsteel #aceroquirurgico #316steel #acero316 #orfebrería #metalwork #metalisteria #arte #art #handmade #hechoamano #electrolisis #electrolysis #cobrakai #pokemon #engrave #grabado #alvinoni #alvinoni77 #alvinoninstagram https://www.instagram.com/p/CHYflHIDDE0/?igshid=9goc7gei657c

#concepts#wip#desing#diseño#vector#plate#placa#aceroinox#inoxsteel#surgicalsteel#aceroquirurgico#316steel#acero316#orfebrería#metalwork#metalisteria#arte#art#handmade#hechoamano#electrolisis#electrolysis#cobrakai#pokemon#engrave#grabado#alvinoni#alvinoni77#alvinoninstagram

0 notes

Text

Ammonium hydrogen fluoride

NH4HF2 is the chemical components of Ammonium hydrogen fluoride. It is been used in metal surface treatment, aluminium anodization, manufacture of wood preservation, building protection, natural gas/ mineral oil drilling, glass processing, cleaning of industrial plants and electronic industry.

In the aluminium industry fluorine, inorganic compounds play a major role. They are not just used for the manufacturing process but during processing and finishing of aluminium.

Introduction of cryolite made the manufacturing of aluminium possible on a commercial scale. Cryolite use decreases the temperature of the smelting flux electrolysis. Cryolite is a major component of electrolyte.

Current commercial additions to electrolytes are used as aluminium fluoride, calcium fluoride and lithium fluoride. These improve the efficiency and increases the conductivity of electrolyte use of energy. Aluminium produced will have the purity of 99.5- 99.9%. Through cleaning and improvement of aluminium is carried out by the three-layer-fused-salt electrolysis. This process is the only commercial process for the production of pure aluminium.

Applications of Ammonium hydrogen fluoride:

• Glass processing:

for matt etching

• Metal surface treatment:

as an essential component of bright digo baths

for etching and cleaning of non-ferrous metal pieces

• Mineral oil / natural gas drilling:

as an aid for drilling through silicate rocks

• Cleaning of industrial plants:

as a component in cleaning and disinfecting solutions, e.g. in power stations

• Building protection:

• as a component in cleaning agents

For free sample report:

https://www.statzyreports.com/index.php

Phone Number

(IN) - +918484035727

(US) - +12094187979

Email Address

Email : [email protected]

Email : [email protected]

0 notes

Text

Persulfates Market Strategic Insights and key Business Influencing Factors | Major Players – MITSUBISHI GAS CHEMICAL COMPANY, INC., ADEKA CORPORATION, vrpersulfates.com.

Persulfates Market are an inorganic compound with more oxygen than normal sulphates. It acts as an oxidizing agent and produced by the electrolysis of a sulfate solution. It is also known as peroxysulfate. It decomposes the material into harmless metal sulfates. Persulfates have many properties like current density, low temperature, strong oxidants with a temperate shelf life using acidic solution owing to oxidation of water. It is used in initiating emulsion polymerization reactions, remediation, TOC analysis, hair bleaching, micro-etching of copper printed circuit boards and many more

The Global Persulfates Market is expected to reach USD 891.6 million by 2025, from USD 570.4 million in 2017 growing at a CAGR of 7.4% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2015 & 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.

Get Sample Report at :

https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-persulfates-market

Competitive Analysis: Global Persulfates Market

Few of the major competitors currently working in Global Persulfates Market are PeroxyChem, United Initiators, Ak-Kim Kimya, MITSUBISHI GAS CHEMICAL COMPANY, INC., ADEKA CORPORATION, vrpersulfates.com. , Hebei Jiheng (Group) Pharmaceutical Co.,Ltd , Fujian Zhanhua Chemical Company , TurkishExporter.Net , LANXESS, ABC Chemical, SHAANXI BAOHUA TECHNOLOGIES CO.,LTD. , Ansin Chemical, Hengshui Jiamu , Powder Pack Chem. and among others.

Key Pointers Covered in the Global Persulfates Market Trends and Forecast to 2026

Global Persulfates Market New Sales Volumes

Global Persulfates Market Replacement Sales Volumes

Global Persulfates Market Installed Base

Global Persulfates Market By Brands

Global Persulfates Market Size

Global Persulfates Market Procedure Volumes

Global Persulfates Market Product Price Analysis

Global Persulfates Market Healthcare Outcomes

Global Persulfates Market Cost of Care Analysis

Global Persulfates Market Regulatory Framework and Changes

Global Persulfates Market Prices and Reimbursement Analysis

Global Persulfates Market Shares in Different Regions

Recent Developments for Global Persulfates Market Competitors

Global Persulfates Market Upcoming Applications

Global Persulfates Market Innovators Study

Get Detailed TOC:

https://www.databridgemarketresearch.com/toc/?dbmr=global-persulfates-market

Market Segmentation: Global Persulfates Market

The global persulfates market is segmented into type, end user and by geography.

Based on type the global persulfates market is segmented into ammonium, sodium, & potassium and others.

On the basis of end user the global persulfates market is classified into polymers, electronics, cosmetics & personal care, pulp, paper & textiles, soil remediation, oil & gas and water treatment and others.

Based on geography the global persulfates market report covers data points for 28 countries across multiple geographies namely north America & south America, Europe, Asia-pacific and, middle east & Africa. Some of the major countries covered in this report are U.S., Canada, Germany, France, U.K., Netherlands, Switzerland, turkey, Russia, china, India, south Korea, japan, Australia, Singapore, Saudi Arabia, south Africa and, brazil among others.

Major Market Drivers and Restraints:

Increasing demand of persulfates in pulp, paper and textiles and the cosmetics & personal care industry.

Growing polymer industry.

Growing demand from the end-use industries.

Issues related to storage and transportation of persulfates.

Inquire Before Buying:

https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-persulfates-market

Key insights in the report:

Complete and distinct analysis of the market drivers and restraints

Key Market players involved in this industry

Detailed analysis of the Market Segmentation

Competitive analysis of the key players involved

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Report Here:

Mirror Coatings Market

Friction Modifiers Market

#Persulfates Market#Persulfates Market share#Persulfates Market size#Persulfates Market trends#Persulfates Market news#Persulfates Market report#Persulfates Market growth

0 notes