#electricpressbrakes

Text

Best Different Sheet metal Machines at an affordable price in India

Hytek Is a solution for all requirements of Machine Tools. We Offer High Technology Solutions for the Sheet Metal and Tube Industry.

For more details: visit

https://www.hytekmarketing.biz/products/product-detail/press-brakes

0 notes

Text

Should I buy a Hydraulic, Electric, or Hybrid Press Brake?

Found yourself in the market for a new press brake? The best (and easiest) first step is to contact your Sales Engineer. Set up a virtual or in-person appointment to review machine options and how they would fit into your production flow. Your Sales Engineer can walk you through options for controls, backgauges, material support, and automation; as well as brainstorm machine capabilities which would assist in growth and increased productivity.

In addition to reviewing options your Sales Engineer can help you decide what tonnage and bed length would suit your needs. They spend their days solving problems for metal fabricators and can offer helpful recommendations from past experiences.

Key factors when asking yourself – “should I buy a Hydraulic, Hybrid, or Electric Press Brake?”

Advantages of a Hydraulic Press Brake

When considering a new hydraulic brake look for a machine with a solid foundation, energy-saving technology, and options that automate the bending process. A well-built hydraulic press brake will have:

· Widest variety of options and configurations

· Configurations from a simple machine to a highly sophisticated machine, with a wide variety in between

· Wide range of budget options

· Potential for significantly higher tonnages and lengths

· Wider variety of tooling options from planer tooling to precision

Heavy-Duty Options

Keep in mind, if you are bending BIG and need 650 to 3000+ ton capability to do it, the High-Tonnage Hydraulic Press Brakes are your answer. These machines are built with oversized components, powerful gauging devices, and increased open heights/stroke lengths. When considering high tonnage, you want a press brake that is tough, durable and will stand up to any forming challenge.

Advantages of an Electric Press Brake

These brakes run on electric motors that turn on during the bending sequence and shut off automatically when not in use. The ram descends quickly, stops at a preset position, creeps downward to make the bend, then moves quickly upward to start the process again. The short list of perks for electric brakes includes:

· High speed and productivity

· Designs (check out the SafanDarley models) require minimal crowning

· Impressively high forming tolerances

· Extremely quiet and clean – make for a nice working environment

· Saving in electricity

Advantages of a Hybrid Press Brake

A hybrid press brake uses both hydraulic cylinder technology and a servo-drive motor – combining the best of both the hydraulic brake and electric brake. They are built with hydraulics to assist the bending process, but without gear pumps. Like an electric press brake, the hybrids shut off to conserve energy when not performing bending functions. A hybrid brake can be 20-30% more energy efficient than a hydraulic press brake.

· Close to the productivity of electric with more size options

· Less drive system maintenance then a hydraulic brake

· Same high tolerances as an electric brake

Which Press Brake Machine Is Best?

Purchasing a new press brake should be like ordering at a restaurant: choosing options based on your preferences and needs, with the goal of ordering a machine built to help achieve your production goals.

Take advantage of your Sales Engineer’s expertise - call to discuss the best choice for your shop!

0 notes

Text

Should I buy a Hydraulic, Electric, or Hybrid Press Brake?

Found yourself in the market for a new press brake? The best (and easiest) first step is to contact your Sales Engineer. Set up a virtual or in-person appointment to review machine options and how they would fit into your production flow. Your Sales Engineer can walk you through options for controls, backgauges, material support, and automation; as well as brainstorm machine capabilities which would assist in growth and increased productivity.

In addition to reviewing options your Sales Engineer can help you decide what tonnage and bed length would suit your needs. They spend their days solving problems for metal fabricators and can offer helpful recommendations from past experiences.

Key factors when asking yourself – “should I buy a Hydraulic, Hybrid, or Electric Press Brake?”

Advantages of a Hydraulic Press Brake

When considering a new hydraulic brake look for a machine with a solid foundation, energy-saving technology, and options that automate the bending process. A well-built hydraulic press brake will have:

Widest variety of options and configurations

Configurations from a simple machine to a highly sophisticated machine, with a wide variety in between

Wide range of budget options

Potential for significantly higher tonnages and lengths

Wider variety of tooling options from planer tooling to precision

Heavy-Duty Options

Keep in mind, if you are bending BIG and need 650 to 3000+ ton capability to do it, the High-Tonnage Hydraulic Press Brakes are your answer. These machines are built with oversized components, powerful gauging devices, and increased open heights/stroke lengths. When considering high tonnage, you want a press brake that is tough, durable and will stand up to any forming challenge.

Advantages of an Electric Press Brake

These brakes run on electric motors that turn on during the bending sequence and shut off automatically when not in use. The ram descends quickly, stops at a preset position, creeps downward to make the bend, then moves quickly upward to start the process again. The short list of perks for electric brakes includes:

High speed and productivity

Designs (check out the SafanDarley models) require minimal crowning

Impressively high forming tolerances

Extremely quiet and clean – make for a nice working environment

Saving in electricity

Advantages of a Hybrid Press Brake

A hybrid press brake uses both hydraulic cylinder technology and a servo-drive motor – combining the best of both the hydraulic brake and electric brake. They are built with hydraulics to assist the bending process, but without gear pumps. Like an electric press brake, the hybrids shut off to conserve energy when not performing bending functions. A hybrid brake can be 20-30% more energy efficient than a hydraulic press brake.

Close to the productivity of electric with more size options

Less drive system maintenance then a hydraulic brake

Same high tolerances as an electric brake

Which Press Brake Machine Is Best?

Purchasing a new press brake should be like ordering at a restaurant: choosing options based on your preferences and needs, with the goal of ordering a machine built to help achieve your production goals.

Take advantage of your Sales Engineer’s expertise - call to discuss the best choice for your shop!

0 notes

Link

The Electric press brake with the new innovation we upgrade our tools and one among them is Electric press brake which is fully upgraded and one generation advanced.

0 notes

Text

4 Things You Need to Know About Electric Brake Technology

Double your bending productivity,increase accuracy, and save money

1. Well-Vetted Technology

Electric brakes have come of age. Hesitations about moving from hydraulic brakes to electric are disappearing as e-brakes become the chosen technology to increase bending capacity in high mix, low-volume shops, as well as large run production.

Draw 50% less power during idle time than a hydraulic brake

Uses less power than hydraulics with energy-efficient servo drives

2. High Accuracy with Less Effort: belt and pulley system

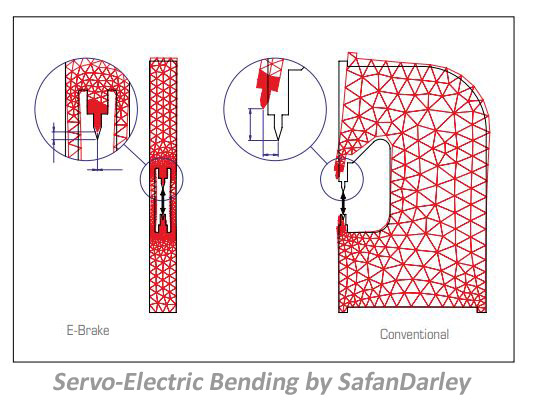

When using hydraulic cylinders an operator must compensate for limited tonnage in the center and correct with crowning. The belt and pulley system virtually eliminates crowning and self- adjusts for tonnage. This is the #1 difference between electric and hydraulic brakes, saving power and time.

"The pulleys are spaced across the length of the beam, allowing an equal distribution of the bending force, which eliminates the need for a crowning table in 95 percent of jobs," said Mauricio Matta from SafanDarley. "The 5% exception is when a user wants to bend with an extreme load, for example, when V-width is less than eight times the sheet thickness."

3. 30% Faster

Cycle times of the SafanDarley E-Brake are far shorter than conventional press brakes due to the active integrated safety system and the acceleration of the servo motors. The SafanDarley E-Brake only uses energy when the top beam is actually moving. This equals an energy saving of up to 50% compared with conventional hydraulic press brakes.

4. More Than a Safety Tool: SafanDarley Integrated Safety System

The integrated safety system can be programmed to allow the upper beam to move within 1mm above the sheet in milliseconds prior to bending allowing the E-Brake to be automatically ready for the next step.

0 notes