#Super Absorbent Polymers industry

Text

Super Absorbent Polymers (SAP) Market Applications, Products, Share, Growth, Insights and Forecasts Report 2028

Industry Analysis

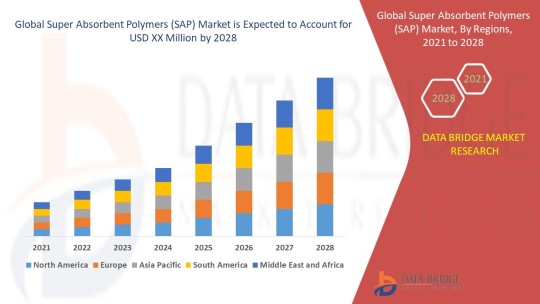

Data Bridge Market Research analyses that the super absorbent polymers (SAP) market will witness a CAGR of 6.63% for the forecast period of 2021-2028. Increase in the demand for super absorbent polymers (SAP) for a wide range of applications such as into personal hygiene, agriculture, medical, industrial and others, growing demand of bio- based super absorbent polymers, and surge in industrialization especially in the developing countries are the major factors attributable to the growth of the super absorbent polymers (SAP) market.

Additionally, the credible Super Absorbent Polymers (SAP) Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Chemical and Materials industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-super-absorbent-polymers-sap-market

Market Insights and Scope

The super absorbent polymers (SAP) are a result of partial bridging of soluble polymers. The super absorbent polymers (SAP) consist of a huge number of hydrophilic groups. The super absorbent polymers (SAP) have a 3- dimensional net structure thus making it suitable for a wide range of household and commercial applications. The super absorbent polymers (SAP) can absorb a huge quantity of water, amounting to various hundred times its weight.

The Super Absorbent Polymers (SAP) Market report encompasses various segments linked to Chemical and Materials industry and market with comprehensive research and analysis. These comprise industry outlook with respect to critical success factors (CSFs), industry dynamics that mainly covers drivers and restraints, market segmentation & value chain analysis, key opportunities, application and technology outlook, regional or geographical insight, country-level analysis, key company profiles, competitive landscape, and company market share analysis. All the data, figures and information are backed up by well recognized analysis tools which include SWOT analysis and Porter’s Five Forces analysis. So, take business to the peak level of growth with the all-inclusive Data Bridge Market research report.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-super-absorbent-polymers-sap-market

Industry Segmentation and Size

The super absorbent polymers (SAP) market is segmented on the basis of type and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

On the basis of type, the super absorbent polymers (SAP) market is segmented into sodium polyacrylate, polyacrylate/ polyacrylamide copolymer and others.

On the basis of application, the super absorbent polymers (SAP) market is segmented into personal hygiene, agriculture, medical, industrial and others.

Market Country Level Analysis

The countries covered in the super absorbent polymers (SAP) market report are

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

A reliable Super Absorbent Polymers (SAP) Market marketing report proves to be the finest and excellent market research report as it is formulated with the following critical factors. These consist of primary research, benchmarking studies, secondary research, company profiles, competitive intelligence & reporting, syndicated research, data collection, data processing and analysis, survey design, and survey programming. The report performs market study and analysis to provide market data by considering new product development from beginning to launch. The Chemical and Materials business report also provides evaluations based on the market type, organization size, availability on-premises, end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa.

Industry Share Analysis

The major players covered in the super absorbent polymers (SAP) market report are

BASF SE, NIPPON SHOKUBAI CO., LTD., Evonik Industries AG, SUMITOMO SEIKA CHEMICALS CO., LTD., LG Chem., SANYO CHEMICAL INDUSTRIES, LTD., Formosa Plastics Group., Kao Corporation., Yixing Danson Technology, Satellite Science & Technology Co.,Ltd., Chase Corp, SONGWON, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA), and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Browse Related Reports@

Global Whiskey Market

South Africa Battery Market

Global Plant-Based Egg Market

Global Nutritional Beverages market

MENA Tahini market

Global Dental Membrane and Bone Graft Substitute Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Super Absorbent Polymers (SAP) Market Growing Popularity#Super Absorbent Polymers (SAP) Market Global Leading Brands#Super Absorbent Polymers (SAP) Market drivers-advantages#Super Absorbent Polymers (SAP) Market Segmentation-CAGR rate#Super Absorbent Polymers (SAP) Market Demands-Size-Share-Top Trends#Super Absorbent Polymers (SAP) Market Industry-Competitors#Super Absorbent Polymers (SAP) Market Growth-Competition#Super Absorbent Polymers (SAP) Market 2028 by Types-Application#Super Absorbent Polymers (SAP) Market Chemical and Materials Industry

1 note

·

View note

Text

Daaaaaaaaaaaaaang wool purists are snooty! I'm watching a video on machine washable wool, and the video starts with a description of how wonderful wool is (water resistant but water absorbant, warm, etc etc), but unfortunately it tends to felt if you're not careful with it. After describing the superwash process (which involves a coating of polymer, I had no idea!), she says "So what do we gain by doing this? Well, the wool is now machine washable and softer." *stares blankly at the camera with cricket sounds*

Oh pardon me, fancy fiberwear lady who thinks unadulterated wool is incomprehensibly superior, some of us have been using acrylic yarn that we can get from the craft store for years and are only just starting to explore wool! The switch from completely plastic yarn to mostly natural and a little bit plastic yarn is so much less intimidating than going directly to something that you have to give so much care to. I've seen so many instances of people not buying something if it says hand wash/dry clean only because "Ain't nobody got time for that!" so the wool now "only" being machine washable is actually a huge deal for people. Plus most people don't spend hours in frigid, windy, wet environments, so all of the main reasons that wool was such a super-fiber back in the day when people were more exposed to the elements are really just not much of a concern anymore. ALSO there's the fact that a lot of people are sensitive to textures and knowing that they can make something that touches their skin without worrying that they have proper under-layers that extend past the edges is pretty great as well.

Don't get me wrong, I think the fact that superwash wool is partially plastic is pretty important information that should be more widely known, but yikes. I will also concede the point that any industrial process is likely rife with all sorts of environmental concerns (the creator said she was an environmental chemist so it's not just "ooh, scary chemicals bad!).

She mentions that she does not judge people for their choices and points out that individual choice and systemic issues are very different things. I still think the video overall comes across as a bit disdainful.

15 notes

·

View notes

Text

Innovations and Opportunities in the Super Absorbent Polymers Market

Super Absorbent Polymers: Revolutionary Materials Absorbing Liquids

Introduction

Super absorbent polymers (SAPs), as the name suggests, are advanced materials with an extraordinarily strong ability to absorb and retain liquids. When immersed in water or other aqueous solutions, SAPs can soak up hundreds of times their own weight in liquid within seconds through a process called gel blocking. This unparalleled absorbency property stems from SAPs' porous, three-dimensional network structure at the molecular level.

Common Applications of SAPs

Despite being relatively new materials, SAPs have carved out an important place for themselves in several industries through their unique water retention qualities. Some of their most widespread applications include:

- Disposable Diapers and Sanitary Pads: SAPs allow diapers and pads to absorb large amounts of urine and other fluids without leakage. They help keep babies and adults dry for longer.

- Agriculture: When mixed with soil, SAPs aid water retention for crops in arid environments. They reduce irrigation needs by absorbing and storing water in the root zone.

- Construction: Sealants, caulks, and other fillers containing SAPs don't crack in the presence of water. This protects buildings from moisture damage.

- Medicine: Wound dressings featuring SAP technology pull liquids away from injury sites. They also maintain a moist healing environment.

- Packaging: Absorbent pads and liners with SAPs soak up meat juices and other liquids in food packaging. This prevents leaks and increases shelf life.

How are SAPs Manufactured?

Most commercially available SAPs are produced through a process of crosslinking polyacrylate or polyacrylamide polymers. These watersoluble polymers are mixed with a crosslinking agent, usually an acrylate or multifunctional monomer. Upon addition of the crosslinker and initiation via heat or radiation, covalent bonds form between the polymer chains.

This crosslinking process transforms the disorganized linear or branched starting polymers into an interconnected three-dimensional network structure with countless pores and interstitial spaces. The surface chemical groups along the polymeric network readily interact with water molecules through hydrogen bonding. Capillary forces then draw liquid into the porous matrix where it gets trapped and retained without draining away.

Properties and Performance

Some key properties of SAPs that impart their super absorbency include:

- Absorption Capacity: Modern SAPs can absorb 100-1000 times their own weight in aqueous solutions within a short time. Laboratory samples have touched absorption ratios of over 2000.

- Gel Strength: The crosslinked network structure provides SAP hydrogels with high gel strength even when fully swollen with liquid. This prevents leakage.

- Swelling Speed: SAPs take only seconds to absorb fluid through their porous morphology. The rapid gel blocking prevents fluids from emerging.

- Return Flow Pressure: Absorbed liquids remain immobilized against external pressures like gravity, movement, or compression during use.

- Salt Tolerance: Absorption is efficient even in solutions with dissolved salts and minerals, unlike many other absorbent materials.

Super Absorbent Polymers of the Future

0 notes

Text

Global Top 5 Companies Accounted for 80% of total Glucose Test Strip Packaging market (QYResearch, 2021)

This report mainly studies Packaging Solutions for Test Strips for Blood Glucose. Based on type, Blood Glucose Test Strip Packaging can be classified into Test Strip Vial Packaging and Single Foil Pouch Packaging.

The packaging materials of Blood Glucose Test Strip mainly include tube / vial and composite aluminium film. The tube/vial body is made of polypropylene (PP), the cover of the cylinder is made of polyethylene (PE) as the main material, and the molecular sieve, silica gel and other adsorbents that absorb water vapor are used as the raw materials. The material of Single Foil Pouch Packaging is mainly composite aluminium film.

Due to the different specifications and parameters of packaging materials such as test strips from different manufacturers of blood glucose test strips, manufacturers of blood glucose test strips usually maintain long-term and stable cooperation with suppliers of fixed test strip packaging materials.

According to the new market research report “Global Glucose Test Strip Packaging Market Report 2023-2029”, published by QYResearch, the global Glucose Test Strip Packaging market size is projected to reach USD 0.03 billion by 2029, at a CAGR of 11.9% during the forecast period.

Figure. Global Glucose Test Strip Packaging Market Size (US$ Million), 2018-2029

Figure. Global Glucose Test Strip Packaging Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Glucose Test Strip Packaging include Sanner GmbH, Shijiazhuang Xinfuda Medical Packaging, Suzhou Super, Hebei Jingtiancheng Plastic Products, Wisesorbent, Airnov Healthcare Packaging, Shanghai Devron, etc. In 2021, the global top five players had a share approximately 80.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Super Absorbent Polymers Market Growing Strong, Current and Future Prospects 2032

According to the research report published by Polaris Market Research, the Global Super Absorbent Polymers Market Size Is Expected To Reach USD 14.67 Billion By 2028, at a CAGR of 6.1% during the forecast period.

Polaris Market Research has recently published its latest report on Super Absorbent Polymer (Sap) Market: By Size, Trends, Share, Growth, Segments, Industry Analysis and Forecast, 2032. It offers a thorough market outlook by providing authentic data to stakeholders, helping them in making strategic decisions. The report covers an analysis of Super Absorbent Polymer (Sap) Market share, size, regions, key segments, and all other important aspects related to the industry.

The study includes all the major developments and innovations in the market. All the major regions and sub-regions are covered to equip readers with an in-depth knowledge of the regional landscape. Besides, it offers crucial data about the obstacles while providing information on overcoming the upcoming challenges in the market.

Competitive Analysis

The study presents the current competitive landscape by analyzing all the Super Absorbent Polymer (Sap) Market key players. It estimates the sales, revenue, market share, as well as the industry ranking of the major players operating in the industry. Besides, this section of the report offers an exclusive understanding of the major growth strategies, such as the introduction of new products and the advent of new trends and developments. Furthermore, readers can find information on mergers, acquisitions, and collaborations in the industry.

The key players operating in the market are:

BASF (Germany)

Nippon Shokubai (Japan)

Evonik (Germany)

LG Chem (South Korea)

Sumitomo (Japan)

SDP Global (Japan)

Formosa (Taiwan)

Satellite Science & Technology Co. Ltd. (China)

Yixing Danson (China)

Kao Corporation (Japan).

Key Market Dynamics

The research study provides dependable insights into the changing market dynamics, covering the Super Absorbent Polymer (Sap) Market trends, challenges, and opportunities. An analysis of various factors that support the industry’s growth is incorporated into the study. It sheds light on the scope of various segments and applications that are anticipated to influence the market over the forecast period. By using these insights, companies can make more informed decisions associated with their business expansion in new regions. Additionally, a thorough examination of the industry drivers provides room for strategic planning.

Access the full report, here: https://www.polarismarketresearch.com/industry-analysis/global-super-absorbent-polymer-sap-market

0 notes

Text

Understanding Super Absorbent Polymers: Properties and Uses

Understanding Super Absorbent Polymers: Properties and Uses

Super absorbent polymers (SAPs) have revolutionized various industries with their remarkable ability to absorb and retain large amounts of liquid relative to their own mass. From personal care products to agriculture and beyond, SAPs play a crucial role in enhancing performance and efficiency. In this blog, we'll delve into the properties and uses of super absorbent polymers, shedding light on their widespread applications and benefits.

Properties of Super Absorbent Polymers

Super absorbent polymers are cross-linked polymer networks capable of absorbing and retaining water molecules through a process called osmosis. Some key properties of SAPs include:

High Absorbency: SAPs can absorb many times their weight in water, making them highly effective in moisture management applications.

Water Retention: Once absorbed, SAPs retain water under pressure, preventing leakage and maintaining their shape and structure.

Gel Formation: Upon absorption, SAPs undergo a gelatinous transformation, transforming into a gel-like substance that immobilizes water molecules.

Chemical Stability: SAPs exhibit chemical stability in various environments, resisting degradation and maintaining their absorbency over time.

Versatility: SAPs can be engineered to exhibit specific properties such as particle size, absorption rate, and gel strength, making them suitable for diverse applications.

Applications of Super Absorbent Polymers

Personal Care Products: SAPs are widely used in personal care products such as diapers, sanitary pads, and adult incontinence products to enhance absorbency and prevent leakage. They provide comfort and dryness for extended periods, improving user experience.

Agriculture: In agriculture, SAPs are employed as soil amendments and water-retaining agents to improve soil moisture retention and reduce water consumption. They help enhance crop yield, particularly in arid regions or during drought conditions.

Packaging: SAPs are used in packaging materials to absorb excess moisture and maintain product freshness during storage and transportation. They prevent spoilage and extend the shelf life of perishable goods such as food and pharmaceuticals.

Medical and Hygiene Products: SAPs are incorporated into wound dressings, surgical pads, and ostomy products to absorb exudate and maintain a moist wound healing environment. They also find applications in absorbent underpads and medical garments for incontinence management.

Hygiene Products: SAPs are used in air fresheners, deodorizers, and pet care products to absorb and neutralize odors, improving indoor air quality and hygiene.

Construction Materials: SAPs are added to construction materials such as cement, mortar, and grout to improve workability, reduce shrinkage, and enhance durability. They help mitigate cracks and enhance moisture resistance in building structures.

Benefits of Super Absorbent Polymers

Enhanced Absorbency: SAPs offer superior absorbency compared to traditional absorbent materials, reducing the frequency of changes and improving efficiency.

Improved Performance: SAPs enhance the performance and functionality of products across various industries, contributing to user comfort, product integrity, and overall satisfaction.

Resource Conservation: By reducing water consumption in agriculture and minimizing product wastage in personal care and packaging, SAPs contribute to resource conservation and sustainability efforts.

Cost-effectiveness: SAPs provide cost-effective solutions by reducing the need for frequent replacements, minimizing product losses, and optimizing resource utilization.

In conclusion, super absorbent polymers play a vital role in diverse industries, offering unmatched absorbency, versatility, and performance. From improving hygiene and comfort in personal care products to enhancing agricultural productivity and resource efficiency, SAPs continue to drive innovation and address evolving needs across global markets. As technology advances and sustainability becomes increasingly important, the applications and benefits of super absorbent polymers are expected to expand, further demonstrating their indispensable role in modern society.

Factory

Gata №34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected]

contact no 91–8800775462

0 notes

Text

Super Absorbent Polymers (SAP) Market Analysis: Assessing Growth Opportunities

Super Absorbent Polymers (SAP) have revolutionized various industries with their exceptional water-absorbing capacity and moisture retention properties. This blog delves into the dynamics of the SAP market, exploring key drivers, diverse applications, emerging trends, and future growth prospects.

Understanding Super Absorbent Polymers (SAP):

Super Absorbent Polymers (SAPs) are hydrophilic polymers capable of absorbing and retaining large amounts of water or aqueous solutions. These polymers are widely used in products requiring moisture management, such as diapers, feminine hygiene products, agriculture, packaging, and medical applications.

Market Dynamics:

Personal Care Industry: SAPs are a vital component in disposable hygiene products such as baby diapers, adult incontinence products, and feminine hygiene products, providing efficient liquid absorption and retention, thereby enhancing product performance.

Agricultural Applications: SAPs are used in agriculture for soil moisture management, water retention in crops, and improving soil structure, leading to water conservation, enhanced plant growth, and reduced irrigation frequency.

Packaging and Consumer Goods: SAPs find applications in packaging materials, food industry (shelf-life extension), and medical products (wound dressings, medical pads) due to their moisture absorption and retention capabilities.

Construction Industry: SAPs are utilized in construction materials such as concrete to improve workability, reduce cracking, and enhance durability by controlling moisture content.

Applications Across Industries:

Personal Care Products: Diapers, sanitary napkins, adult incontinence products.

Agriculture: Soil moisture management, crop protection, water-saving technologies.

Packaging: Food packaging, moisture-sensitive goods protection.

Construction: Concrete additives, moisture control in building materials.

Market Trends:

Biodegradable and Sustainable SAPs: Growing environmental concerns have led to the development of bio-based and biodegradable SAPs, aligning with sustainability goals and eco-friendly product demands.

Advanced Functionalities: Research and development efforts focus on enhancing SAP properties such as absorption rate, liquid retention under pressure, gel strength, and compatibility with various formulations and applications.

Smart SAPs: Integration of SAPs with smart technologies for moisture sensing, controlled release of substances, and responsive functionalities in diverse applications, catering to evolving market needs.

Future Prospects:

The global Super Absorbent Polymers market is poised for substantial growth, driven by increasing demand from key industries, technological advancements, and sustainability initiatives. As industries emphasize efficiency, sustainability, and product performance, SAPs play a pivotal role in meeting these requirements across diverse applications.

Conclusion:

Super Absorbent Polymers have transformed industries by providing innovative solutions for moisture management and liquid retention. Navigating the SAP market requires a keen understanding of evolving trends, customer demands, and technological innovations. With a focus on sustainability, performance enhancement, and expanding application areas, SAPs are set to witness significant growth and adoption, contributing to enhanced product functionalities and environmental stewardship in various sectors worldwide.

0 notes

Text

What Makes Super Absorbent Polymer Exceptional? | Chemtex Speciality Limited

Dive into the Polymers (SAPs) and uncover how they master the art of water locking, revolutionizing moisture management across industries.

#superabsorbentpolymer#sodiumpolyacrylate#sappolymer#polymermanufacturer#artificialsnow#waterretaining#chemtex#chemicalmanufacturer

0 notes

Text

Super Absorbent Polymers Market: A Comprehensive Analysis

Super Absorbent Polymers: The Future of Absorbency

Super absorbent polymers (SAPs) are a type of polymer material that can absorb and retain extremely large amounts of liquid relative to their own mass. These polymers are playing an increasingly important role in everyday life through their use in absorbent hygiene products like diapers and feminine care products, as well as in agriculture and biomedical applications. In this article, we will explore the fascinating world of super absorbent polymers and how they are revolutionizing industries.

History and Development of SAPs

The development of super absorbent polymers can be traced back to the 1960s when researchers started investigating absorbent materials that could help address the growing demands for hygiene products. Early SAPs were based on starch-acrylonitrile graft copolymers. However, it wasn't until the early 1980s that highly absorbent acrylate-based polymers were developed which led to a rise in their commercial use.

Today, the most commonly used SAPs are based on crosslinked polyacrylate polymers. These polymers can absorb hundreds of times their own weight in aqueous liquids within seconds through a process called osmotic swelling. The absorption occurs through a mechanism where sodium ions in the liquid displace hydrogen ions in the polymer to form crosslinks that trap the liquid inside gel-like networks. Continuous research and development has led to SAPs with even higher absorption capabilities and faster swelling rates.

Uses and Applications of SAPs

The most prevalent use of super absorbent polymers is in hygiene products like baby diapers, adult incontinence pads, and feminine hygiene products. SAPs allow these products to absorb large volumes of fluid with minimal increase in product bulk. As a result, SAPs have helped revolutionize hygiene products by making them smaller, thinner and more comfortable to wear. It is estimated that over 90% of disposable diapers now contain SAPs.

Another major application is in agriculture and horticulture for water retention in soil. SAPs are increasingly being used as soil conditioners and additives in potting mixes to control moisture levels and reduce irrigation needs. The hydrogel structures formed by the polymers help retain water for plant use while also improving soil aeration and structure. Certain SAPs are also being developed to slowly release nutrients or fertilizers over time.

More recent areas of research involve using SAPs for biomedical applications like wound dressings, drug delivery carriers, and super absorbent wound care products. Their high moisture retention capacity makes them well suited for helping manage chronic wound exudates and promoting faster healing. In the future, intelligent SAPs could play a role in developing smart wound care dressings integrated with sensors and feedback mechanisms.

Environmental and Economic Impact

The rise of super absorbent polymers has brought both economic and environmental benefits. From an economic standpoint, even a small amount of SAP incorporated into hygiene products allows manufacturers to significantly reduce raw material costs by using less pulp fluff or cotton fibers. This has helped lower product costs for consumers.

On the environmental front, SAPs have diminished landfill waste volumes. Their high absorbency means smaller, lighter disposable products that take up less space in landfills. Agricultural uses of SAPs translate to significant water savings compared to conventional irrigation methods. Some studies estimate a 30-50% reduction in water needs for certain crops with SAP soil additives. Overall, the absorption capabilities of these materials are helping optimize resource usage across industries.

#Super Absorbent Polymers Market#Super Absorbent Polymers Market Trends#Super Absorbent Polymers Market Growth

0 notes

Text

Super Absorbent Polymers (SAP) Market Leading Brands and Business Opportunities

Industry Analysis

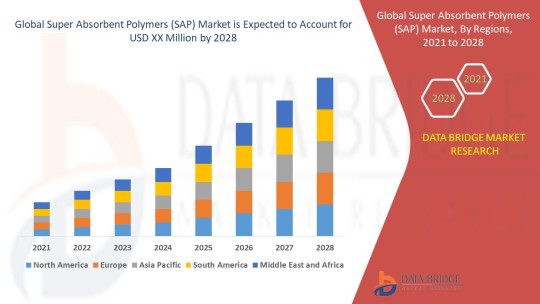

Data Bridge Market Research analyses that the super absorbent polymers (SAP) market will witness a CAGR of 6.63% for the forecast period of 2021-2028.

Additionally, the credible Super Absorbent Polymers (SAP) Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Chemical and Materials industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-super-absorbent-polymers-sap-market

Market Insights and Scope

The super absorbent polymers (SAP) are a result of partial bridging of soluble polymers. The super absorbent polymers (SAP) consist of a huge number of hydrophilic groups. The super absorbent polymers (SAP) have a 3- dimensional net structure thus making it suitable for a wide range of household and commercial applications. The super absorbent polymers (SAP) can absorb a huge quantity of water, amounting to various hundred times its weight.

The wide-ranging Data Bridge market report covers an array of aspects of the market analysis which today’s businesses call for. This market document also defines a chapter on the global market and allied companies with their profiles, which provides important data pertaining to their insights in terms of finances, product portfolios, investment plans, and marketing and business strategies. This market research report is generated with a nice blend of industry insight, talent solutions, practical solutions and use of technology to advance user experience. An outstanding Data Bridge market report puts light on many aspects related to Chemical and Materials industry and market.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-super-absorbent-polymers-sap-market

Industry Segmentation

The super absorbent polymers (SAP) market is segmented on the basis of type and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

On the basis of type, the super absorbent polymers (SAP) market is segmented into sodium polyacrylate, polyacrylate/ polyacrylamide copolymer and others.

On the basis of application, the super absorbent polymers (SAP) market is segmented into personal hygiene, agriculture, medical, industrial and others.

Market Country Level Analysis

The countries covered in the super absorbent polymers (SAP) market report are

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

An influential Super Absorbent Polymers (SAP) Market research report displays an absolute outline of the market that considers various aspects such as product definition, customary vendor landscape, and market segmentation. Currently, businesses are relying on the diverse segments covered in the market research report to a great extent which gives them better insights to drive the business on the right track. The competitive analysis brings into light a clear insight about the market share analysis and actions of the key industry players. With this info, businesses can successfully make decisions about business strategies to accomplish maximum return on investment (ROI).

Industry Share Analysis

The major players covered in the super absorbent polymers (SAP) market report are

BASF SE, NIPPON SHOKUBAI CO., LTD., Evonik Industries AG, SUMITOMO SEIKA CHEMICALS CO.,LTD., LG Chem., SANYO CHEMICAL INDUSTRIES, LTD., Formosa Plastics Group., Kao Corporation., Yixing Danson Technology, Satellite Science & Technology Co.,Ltd., Chase Corp, SONGWON, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA), and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get TOC Details: https://www.databridgemarketresearch.com/toc/?dbmr=global-super-absorbent-polymers-sap-market

Browse Related Reports@

Global Nutritional Beverages market

Global Oral Care/Oral Hygiene Products Market

Global Warehouse Management Logistics Market

Global Carpets & Rugs Market

Global 1, 4-Cyclohexanedimethanol Dibenzoate Market

U.S. Tahini Market

Europe Customer Journey Analytics Market

West Africa Shisha Tobacco Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Super Absorbent Polymers (SAP) Market Growing Popularity and Traffic#Super Absorbent Polymers (SAP) Market Global Leading Brands and Businesses#Super Absorbent Polymers (SAP) Market drivers-advantages-restraints and challenges#Super Absorbent Polymers (SAP) Market Value-Segmentation-CAGR rate-Future Trends to 2028#Super Absorbent Polymers (SAP) Market Demands-Size-Share-Top Trends#Super Absorbent Polymers (SAP) Market Industry Insights-Country-Competitors Research#Super Absorbent Polymers (SAP) Market Growth-Competition-Scenario-Outlook#Super Absorbent Polymers (SAP) Market Global Opportunity Analysis#Super Absorbent Polymers (SAP) Market 2028 by Product-Types-Procedure-Application-End User#Super Absorbent Polymers (SAP) Market Chemical and Materials Industry

1 note

·

View note

Text

0 notes

Text

Revolutionizing Absorption: The Power of Super Absorbent Polymers in Modern Applications

Super Absorbent Polymers: The Role of Absorbent Polymers in Advanced Diapers, Sanitary Pads, and Wound Dressings

Introduction to SAP

Super absorbent polymers (SAPs) are advanced materials that can absorb and retain extremely large amounts of a liquid relative to their own mass. When dry, SAPs feel like normal plastic or powder but once they absorb liquid, they become a soft gel. This absorption occurs via osmotic pressure which draws the liquid into the SAP where it is trapped in the polymer matrix.

Chemistry and Structure of SAPs

The vast majority of commercial SAPs are either polyacrylate or polyacrylamide based. These polymers contain repeating units of acrylic acid or acrylamide monomers that provide carboxylate or amide functional groups. These functional groups are responsible for the swelling and absorption capabilities of SAPs. The backbone polymers chains allow for branching and crosslinking that maintains the absorbent three-dimensional network structure even when fully swollen with liquid. Without this crosslinking, the polymer would dissolve rather than form a gel upon swelling.

Applications in Hygiene Products

One of the largest applications of SAPs is in baby diapers, adult incontinence products, and feminine hygiene items. SAP particles are blended into these products to rapidly absorb urine and other body fluids away from the skin. This helps keep the wearer dry and comfortable. A single gram of SAP can absorb up to 100 mL of liquid. Modern ultra-thin diapers contain 20-30% SAP by weight which allows them to absorb multiple insults of liquid with a dry feel. Over 90% of disposable diapers worldwide contain SAP.

Use in Agriculture and Horticulture

SAPs are valuable for water retention in soil used for agriculture and gardening. When SAP particles are mixed into soil or soilless potting mixes, they absorb water from irrigation and release it slowly over time as the plants need it. This reduces the need for frequent watering. SAPs are also used for long-term water storage in seed coats to promote germination even in dry conditions. Some greenhouse growers add SAPs to hydroponic systems and floating raft technologies to maximize water and nutrient availability to plant roots.

Medical and Biomedical Applications

Due to their absorbency and biocompatibility, SAPs have promising applications in medicine. They can be used as carrier materials for controlled drug delivery, either absorbing drugs and releasing them gradually or swelling in response to stimuli like pH to trigger drug release. SAP hydrogels are also being developed as wound dressings to absorb drainage and keep wounds moist for healing. In biomedical areas, SAPs show potential for cell culture scaffolds, implants, and even artificial tissues due to their swelling abilities.

Other Uses of SAP Technology

Beyond hygiene and agriculture, SAPs have diverse industrial and commercial applications as well. To generate and store moisture, they can be used in products like detergents, clothes, shoes, and building materials. SAPs are integral to industrial processes like water treatment and purifications where they help absorb contaminants and concentrate desired components. Due to their swelling behavior, some super absorbent polymers formulations are being developed for emerging uses like actuator devices, artificial muscles, and sensors. Their absorbency also makes them valuable for spill/leak control and cleanup in oilfields, marine, and industrial settings. SAPs continue expanding into new applications as their unique material properties are applied in new technologies.

0 notes

Text

Swellable Water Bar: A Comprehensive Guide

Introduction

Waterproofing is a crucial aspect of construction, especially in areas prone to water infiltration. Swellable water bars, also known as hydrophilic water stops, are effective solutions for preventing water penetration in construction joints. These bars expand upon contact with water, creating a tight seal that prevents leaks and seepage.

What are Swellable Water Bars?

Swellable water bars are flexible strips made from super absorbent polymers that expand upon contact with water. They are typically installed along construction joints in concrete structures, such as basements, tunnels, and retaining walls. When water enters the joint, the bar swells, forming a watertight seal that prevents further water ingress.

Deesawala Rubber Industries: A Trusted Swellable Water Bar Manufacturer

Deesawala Rubber Industries is a leading manufacturer of swellable water bars, offering a range of products to suit various construction needs. Their swellable water bars are known for their high quality, durability, and effectiveness in preventing water penetration

Swellable Water Bar Manufacturers, Swellable Water Bar Dealers

#Swellable Water Bar#Swellable water bars#Swellable Water Bar Manufacturer#manufacturer of swellable water bars#Swellable Water Bar Manufacturers#Swellable Water Bar Dealers

0 notes

Text

Sanitary Napkin Raw Material Suppliers in Kolkata: What You Need to Know

When it comes to manufacturing sanitary napkins, sourcing high-quality raw materials is crucial to ensuring the efficacy and safety of the end product. In Kolkata, a bustling hub of industry and commerce, finding reliable suppliers for these materials is essential for businesses in the hygiene products sector. In this blog post, we'll explore what you need to know about sanitary napkin raw material suppliers in Kolkata.

Quality Standards: When selecting a supplier for sanitary napkin raw materials, it's imperative to prioritize quality. Look for suppliers who adhere to stringent quality standards and certifications. Materials such as absorbent cores, top sheets, and back sheets should meet industry benchmarks for hygiene and safety.

Product Range: Consider suppliers who offer a diverse range of raw materials to meet your specific requirements. Whether you need fluff pulp, SAP (Super Absorbent Polymer), non-woven fabrics, or adhesive materials, choose a supplier with a comprehensive product portfolio to fulfill all your needs under one roof.

Reliability and Consistency: Reliability is key when it comes to raw material suppliers. Opt for suppliers with a track record of consistency in product quality, delivery timelines, and customer service. A reliable supplier ensures uninterrupted production and minimizes the risk of delays or quality issues.

Customization Options: Every sanitary napkin manufacturer may have unique specifications or preferences for their products. Look for suppliers who offer customization options such as tailored absorbency levels, sizes, or packaging formats to align with your brand's requirements.

Cost-effectiveness: While quality is paramount, cost-effectiveness also plays a significant role in supplier selection. Compare prices and evaluate the overall value proposition offered by different suppliers. Consider factors such as bulk discounts, payment terms, and logistics costs to optimize your procurement process.

Environmental Sustainability: In today's eco-conscious landscape, sustainability is increasingly becoming a priority for businesses across industries. Choose suppliers who prioritize eco-friendly practices and offer sustainable alternatives such as biodegradable or recycled materials, helping you reduce your environmental footprint.

Local Presence and Support: Opting for local suppliers in Kolkata can offer advantages such as shorter lead times, reduced transportation costs, and easier communication. Additionally, local suppliers may provide better support and responsiveness to address any issues or concerns promptly.

Industry Reputation and Reviews: Conduct thorough research on prospective suppliers by seeking out reviews, testimonials, or references from other businesses in the industry. A supplier's reputation and feedback from existing clients can provide valuable insights into their reliability, product quality, and customer service.

In conclusion, choosing the right sanitary napkin raw material supplier in Kolkata requires careful consideration of factors such as quality, reliability, customization options, cost-effectiveness, sustainability, and local presence. By partnering with reputable suppliers who meet your specific needs and standards, you can ensure the consistent production of high-quality sanitary napkins that meet the demands of your customers while contributing to your business's success.

Adress

Gata No. 34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected]

contact no 91-8800775462

1 note

·

View note

Text

Frequent vibration of industrial equipment, how to solve the traditional damping pad damping insufficient difficult pain point problem

Frequent shock absorption for industrial equipment, traditional rubber shock absorbers and shock pads, spring dampers shock absorption is not enough boss difficult, its pain points mainly include the following points:

Shock absorption effect is limited: for industrial equipment, the traditional rubber shock absorbers and shock pads, spring dampers are often not effective in absorbing and transforming the ineffective shock or kinetic energy generated during the operation of the equipment, resulting in high-frequency vibration and strong shaking of the equipment running, affecting the performance and service life of the equipment.

Difficult to adapt to complex working conditions: the operating environment and working conditions of industrial equipment are usually more complex, the traditional rubber shock absorbers and shock pads, spring dampers may be difficult to adapt to such complex environments, such as high temperature, low temperature, corrosion, etc., especially easy to age, thus affecting its damping effect.

Installation and maintenance difficulties: traditional rubber shock absorbers and shock pads, spring dampers installation and maintenance may require specialized technicians, and replacement is difficult, often do not get effective maintenance, which not only increases the cost of use, but also increases the risk of equipment damage.

In order to solve the above pain point problems, new vibration damping technologies and materials can be considered.

New vibration damping technologies and materials, such as polymer materials, composite materials, etc., have been widely used in the field of industrial equipment vibration damping in recent years. Among them, ACF artificial cartilage material synthesized shock absorbing pad shock absorbing sheet is a new type of material with excellent shock absorbing performance

ACF artificial cartilage material is a kind of polymer super-material, with similar natural cartilage elasticity and shock absorption performance, it has the highest can absorb 97.1% of the impact force, is the performance of other traditional materials shock absorber 3-5 times, at the same time has other traditional shock absorbing cushion shock absorber shock absorber bearing single or a small number of attributes, do not have a comprehensive multifunctional attributes: ACF material has a high resistance to deformation (ASTM) D3574-17 TEST J test), durable and reliable (ASTM D746-20 test), good resistance to hydrolysis, solvent resistance (GB/T 11547-2008 test), long life and environmental protection (QB/T 2881-2013 test) and other advantages.

By synthesizing this metamaterial, it is possible to create shims or shock absorbing sheets with excellent vibration damping properties. These shock absorbing pads and shocks have the following advantages:

Excellent shock absorbing effect: the elasticity and shock absorbing property of ACF artificial cartilage material makes the pads or shock absorbing sheets can effectively absorb and transform the ineffective shock or kinetic energy generated during the operation of the equipment, so as to effectively reduce the vibration and shaking of the equipment.

Strong adaptability: ACF artificial cartilage material is resistant to high temperature, low temperature, corrosion and other characteristics, can adapt to a variety of complex working conditions, to ensure the stability and durability of the shock absorbing pads and shocks.

Easy to install and maintain: the installation and maintenance of the new vibration damping pads usually do not require professional technicians, can be easily disassembled and replaced, reducing the cost of use and the risk of equipment damage.

By adopting these new vibration-damping technologies and new vibration-damping materials, we can effectively improve the vibration-damping effect and adaptability of production equipment, reduce the cost of use and the risk of equipment damage, and improve the safety and reliability of equipment. It can also effectively do the upgrading of industry. For China's manufacturing upgrading of China's smart manufacturing to add a strong impetus.

400-6543-699

www.acf.com

0 notes