#Industrial Paper Shredder manufacture

Text

Shredding Machine in Chennai - Shredding Machine Manufacturers

Avanti Shredding Machine in Chennai is offering industrial shredder which Shredding Machine is used to break down materials for various applications such as recycling, paper, volume reduction, and other product destruction. Shredding Machine Manufacturers are offering many different sizes and design variations based on what particle size is needed for final shredded product. Contact Electronic Waste Shredders Manufacturers in Tamil Nadu o buy Shredding Machine in Hyderabad. Web Link:- https://www.avanti-ltd.com/

0 notes

Text

What Are the New Innovations in the Market for Plastic Lump Shredder Machine Technology?

The plastic lump shredder machine technology has seen significant advancements, responding to the increasing demand for efficient recycling solutions. Innovations in this field aim to enhance performance, sustainability, and the quality of the output material. Here, we delve into some of the latest innovations that are setting new standards in the recycling industry.

Enhanced Shredding Efficiency

Why is efficiency paramount in plastic shredding? In the bustling world of recycling, the ability to process materials quickly and effectively isn’t just a bonus—it’s a necessity. Machines like the WLK 4 and WLK 1500 from WEIMA don’t just meet these expectations; they redefine them. These models, known for their compact yet powerful designs, have set a new benchmark for what we consider efficient shredding,

Compact Design, Big Impact: The WLK series is a testament to the ingenuity of modern engineering. Despite their small footprint, these machines pack a punch, capable of handling small to medium throughput rates without breaking a sweat.

Robustness and Versatility: Don’t let their size fool you. These machines are built to last, with a design that emphasizes durability and a wide range of applications. Whether it’s integrating seamlessly into production lines or offering a variety of cutting geometries, the WLK series stands out as a versatile solution in the plastic recycling industry.

Dual Shaft Shredders: Versatility in Action

When it comes to shredding, one size doesn’t fit all. The needs of the recycling industry are as varied as the materials it processes. CM Shredders’ lineup, including models from the CM H-10 to the CM H-250L, showcases the importance of having the right tool for the job. From light-duty tasks like shredding paper and plastics to heavy-duty challenges involving general refuse and metal alloys, these machines offer a tailored approach to material reduction.

Light to Heavy-Duty Applications: Whether you’re dealing with everyday items or tackling tougher materials, there’s a CM shredder that’s up to the task.

A Model for Every Need: The diversity in CM’s range means that no matter your specific requirements, there’s a shredder designed to meet them, ensuring efficiency and effectiveness in your recycling process.

Innovative Shredder Designs: PURE LOOP’s Revolution

Innovation is the heartbeat of progress, and PURE LOOP’s shredding technology exemplifies this principle. The introduction of a single shaft shredder equipped with a double feed ram system and a conical transition isn’t just an advancement; it’s a revolution. This system caters to a variety of materials with different bulk densities, ensuring continuous, uniform extrusion filling.

Double Feed Ram System: A groundbreaking feature that propels the shredding process into a new era of efficiency. By facilitating the movement of shredded material through the conical transition and into the extruder, it easily accommodates materials of varying bulk densities.

Conical Transition: The unsung hero of the shredding process. This component is crucial for compacting material and reducing oxygen, guaranteeing a gentle processing method that’s both efficient and effective.

Comprehensive Shredding Solutions: The Genox Edge

What sets Genox Recycling Technology apart in the plastic shredding industry? It’s their commitment to offering comprehensive, cost-effective solutions tailored to the specific needs of recycling operations. Genox’s systems are optimized for various materials, ensuring that each shredding task, from plastic pipes and purgings to films and bottles, is executed with precision and minimal maintenance requirements.

Key Features:

Optimized Cutting Speed and Size Reduction: By tailoring their machines to the material type and application, Genox ensures efficient processing and high-quality output.

In-House Manufactured Components: Accuracy and reliability are guaranteed with components machined using modern CNC equipment, reflecting Genox’s dedication to quality.

Advanced Material Processing: Beyond Shredding

In the quest for innovation, the focus isn’t solely on the machines and the materials they process. The ability to handle a variety of complex materials efficiently is what differentiates the latest plastic lump shredder machines. This adaptability is crucial for recycling facilities aiming to expand their capabilities and improve the quality of their output material.

Considerations for Advanced Material Processing:

Diverse Material Types: From heavy, bulky items to lightweight, highly tear-resistant plastics, the range of materials that modern shredders can process is impressive.

Quality of Output: The innovations in shredder technology not only focus on the shredding process itself but also the quality of the material after processing. This is vital for ensuring the material is ready for the next stage of recycling.

These advancements in shredder technology and material processing illustrate the industry’s progress toward more efficient, versatile, and sustainable recycling solutions. By embracing these innovations, recycling operations can not only improve their efficiency but also contribute to a more sustainable future by ensuring high-quality recycling outputs.

Conclusion

EnvCure stands at the forefront of addressing environmental sustainability challenges, including the recycling of plastic waste. By leveraging the latest innovations in plastic shredder machine technology, EnvCure is well-positioned to offer cutting-edge solutions that not only meet the demands of waste management but also contribute significantly to environmental conservation. With a deep commitment to innovation and sustainability, we continue to develop products and solutions that support the global movement towards a more sustainable future.

By incorporating these advanced technologies, the recycling process becomes more efficient, contributing to a reduction in plastic waste and promoting a circular economy. The adaptability and efficiency of the latest plastic lump shredder machines are critical for industries seeking to enhance their sustainability practices while ensuring high-quality recycling outputs.

Source URL:

0 notes

Text

WANROOETECH Dual-motor Single Shaft Shredder is aslo popular as two-motor single rotor shredder or dual-motor one shaft shredder. It is a multi-purpose shredding machine which can be available for shredding a wide range of material including plastic, rubber, wood, paper and animal bone etc. Designed with a high-speed rotary cutter along with a hydraulic-driven movable press-plate of cutter, this industrial shredder makes the shredding job done in a super efficient and effective way. The rotary cutter is reversible and controlled by PLC system, which well protects the shredding equipment when some stubborn material gets stuck in the shredding chamber. Operation of this single shaft shredder for sale is straight-forward, just pressing the buttons on the control panel to control every movement. And “auto mode” can be available on the control panel for automatic operation to increase working efficiency and meanwhile save labor. Double-roller shredder of WANROOETECH are designed and manufactured for recycling wide range of waste materials, for example, plastic, rubber, paper, wood, etc. Espeicalaly, it has the higher working efficiency for films and woven bags than the double-shaft shredder. But It is different from the double-shaft shredder because it has the same rotor and blades as single-shaft shredder. By different requirements such as the input and output size of the material, capacity, etc, WANROOETECH can work out the best suitable proposal to meet our customer's request.

0 notes

Text

What Is the Modern Technology in Steel Mill Equipment?

According to historical reports, reinforcing the steel production process takes much time. Although making the useful and enough equipment is getting more complex, producers can reach the desired point to produce almost 200000 tons of steel every day, more than enough to rebuild the Golden Gate Bridge 2 times over these days. This short post will give you an overview of the process within a hot steel mill. These days, as everything is changing and improving positively, steel mill equipment is also getting better and more modern. In the first steps, modern technology will process the steel material plastically at very high temperatures. On the other side, the rotating roles will reduce the thickness of the usable material. In the following, they will produce long strips. It is good to know these long strips are functional and practical for manufacturing products like steel plates.

How Does Steel Mill Equipment Work?

According to a professional at GMB Heavy Industries, the steel mill process has various stages of the hot rolling process. This process also needs enough knowledge and experience to produce high-quality products. In this process, the coral comes in box style. Then, the production will finish in the final part of the mill.

Before the steel mill equipment processes the slab, it must get hot enough. The slab is continuously cast and has the dimensions essential for a correct weight, width, and thickness final product.

Knowing that this equipment feeds the material through modern technology is essential. The elements of the materials are the most important thing to consider. If materials are not sufficiently heated in the correct process, the final result will not be based on the desired expectations.

You may not believe or understand it, but one of the great deals of the production process relates to its recycling process. Based on the gathered information and reports, steel is the most recycled material on our planet, more than any other material:

Aluminum

Copper

Paper

Glass

Plastic

Why Do We Need Steel Mill Equipment?

With the development boom sweeping the nation, steel production is moving more than its fair share of that to keep up with demand. So, in this case, the equipment is helpful through the steel mill process.

Of course, using this modern equipment has its challenges. Based on the inspectors' opinions from their daily search for impurities, it is crucial to have enough steel equipment in this century because the production needs and rates are increasing.

Unfortunately, the big problem in this process is equipment usage. Sometimes, it stops working because they need the observation and check-up. Therefore, it is crucial to have enough experts in this field who are familiar with the modern technology in the steel mill process and know enough about the equipment.

Lack of knowledge may damage the shredder and cause a thousand-pound deduction to render safely. Modern equipment can help the steel mill process positively. It also can increase both quality and capacity based on standards.

0 notes

Text

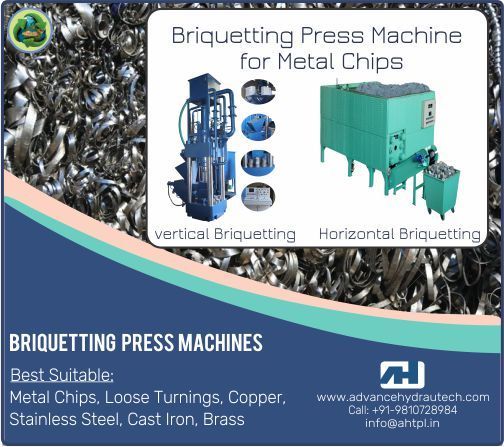

Aluminium Chips Briquetting Machine, Automatic Horizontal Metal Chip Briquetting Press

Our Metal Chip Briquetting machine is designed to turn fine or loose particles and residues into hard, dense briquettes or pucks. The briquetting machines manufacture by Advance Hydrau-Tech is the ideal solution for getting high-quality briquettes from a variety of metals such as steel, aluminium, cast iron, brass, copper, etc. We have vertical and horizontal briquetting machines compacts the metal dust or chips into highly dense and dry briquettes. We are India’s largest manufacturer of scrap processing machines dealing with wide range of recycling machines. Our scrap baler, shear, metal shredder, briquetting, paper baler, automatic balers are widely used and most reliable machines in recycling industries.

youtube

0 notes

Text

Scrap Grinder Supplier in Jammu

Scrap Grinder Supplier in Jammu:

Invoit Plast Machinery Pvt. Ltd.

Plastic processing machine manufacturer, supplier, and exporter Invoit Plast Machinery Pvt. Ltd.

A scrap grinder, also known as a plastic grinder or shredder, is a machine designed to reduce plastic and other materials into smaller, more manageable pieces. Its primary function is to process and recycle various forms of industrial scrap, post-consumer waste, or rejected products into reusable raw materials.

Applications of Scrap Grinders

Scrap grinders are versatile machines with a wide range of applications:

Plastic Recycling: Plastic recycling plants commonly use them to grind plastic waste into granules for manufacturing new plastic products.

Rubber Recycling: In the rubber industry, they use scrap grinders to recycle rubber waste into reusable materials.

Paper Shredding: They play a role in recycling paper products, reducing the need for cutting down more trees.

Electronic Waste: Scrap grinders can process electronic components to recover valuable metals and components.

Wood Recycling: In the woodworking industry, scrap grinders help convert wood waste into useful wood chips or sawdust.

Metal Recycling: Some scrap grinders are adapted to process metal scrap, aiding in the recovery of valuable metals.

Textile Recycling: In the textile industry, they shred textiles into fibers that can be used in new fabric production.

We Provide Scrap Grinder Supplier in Jammu Including Srinagar, Udhampur, Anantnag, Kathua, Rajouri, Baramulla, Pulwama, Doda, Ganderbal, Kupwara, Kishtwar, Kulgam, Leh, Akhnoor, Budgam, Gulmarg, Arnia, Khour, Katra, Sonamarg, Bijbehara, Ranbir Singh Pora, and Bhaderwah.

Read the full article

0 notes

Text

10 Types of Recycling Machines

Every day, our persistent production of waste products poses major environmental and health risks in all nations. Poor waste management practices and indiscriminate, improper residential litter disposal practices have made significant contributions to environmental degradation and ecological decline.

Recognising the potential harm caused by waste, nations and businesses urge appropriate rubbish recycling to reduce the amount of trash dumped in landfills and other locations that could contaminate the environment. A good waste management system also lowers carbon emissions since recycling requires less energy than producing new goods to replace what has been used and thrown away.

Additionally, recycling is a lucrative industry. People can find a lot of jobs thanks to it. You are creating jobs for people, whether you are constructing a sizable processing facility using labelling or decorating machines for recycling waste or a tiny cooperative enterprise in the neighbourhood to come up with innovative ways to reuse and recycle trash.

Recycling is the only alternative for these materials because the government also forbids the disposal of some wastes in landfills. Businesses and landfill sites must manage waste and trash on a continual basis; thus, they prefer to use waste recycling machines for their convenience.

Following are some types of recycling equipment and their intended uses:

1. Bag Opener

With the use of this device, bags can be opened without needing to be cut, preserving the contents. Due to this machine’s modular design, you can modify it to accommodate different bag types and sizes.

2. Conveyor Belts

Conveyor belts are a permanent fixture in any manufacturing or processing facility of industrial calibre. This recycling machine is crucial for moving raw materials between processing units and for moving finished goods from the processing facility to the packing area. The conveyor belt will automatically and effectively move whatever is needed.

3. Separators

Its function is to separate various waste or garbage types; it is also known as a sorting machine. To distinguish the different waste types and separate them from the others, use a disc screener or filter. This machine may be altered to filter various kinds of trash, making it very adaptable. It can be used to sort wood from stones, get rid of liquids, or separate metals from other materials.

4. Universal Shredder

For recycling, shredders are very necessary. The device is in charge of shredding the waste into more manageable pieces. Before transferring waste to another processing recycling machines, whether it be plastic, paper, or another type of waste, it is crucial to cut it up first.

5. Baling Press

A baling press is a crucial piece of recycling machines. They compress trash into bundles or bales that are firmly packed. After initial processing, trash is frequently retained in storage or compressed into bales for shipment to another facility to finish the recycling process.

6. Paper Refiner

A paper refiner would be essential to a recycling facility that specialises in recycling paper in order to ensure that the completed product is of the highest calibre. By improving the fibres’ ability to bind with one another, a paper refiner improves the strength and smoothness of recycled paper.

7. Granulators

This device crushes or chops garbage into minute particles or granules. Waste products produced by labelling or decorating machines in granule form are simpler to move or store. Before moving on to the next procedure, it could also be essential to grind the components into granules.

8. Rotatory Shears

This recycling machines has a double-shaft crusher, a high torque motor, and a moderate rotational speed. It is perfect for shredding large amounts of wire, plastic, metal, and other debris into smaller bits.

9. Reel Splitters

Both a mechanical and a hydraulic version of this machine are available. It is employed to split the paper product from the core and cut troublesome or flawed paper reels. Following separation and cutting, the paper will go through another procedure to finish recycling. Some reel splitters can also be set up to cut aluminium reels in addition to paper. Additionally, it can be used to cut compressed bundles of raw materials in bales.

10. Centrifuge Separator

This machine is perfect for plastic-specific recycling processing facilities. It is employed to tidy up, dry, and sort various kinds of crushed plastic materials. The centrifuge separator’s rotor rotates at a speed of 1,500 revolutions per minute. On the other hand, the perforated trommel moves anticlockwise. While the lighter non-plastic items and water are separated through the perforated trommel and discarded, the heavy plastic will sink to the bottom.

To Conclude,

The broad range of recycling machines covered in this overview exemplifies waste management innovation and a dedication to sustainability. These machines, which include everything from plastic shredders to can crushers, are crucial to the recycling process because they reduce waste, conserve resources, and have little adverse environmental impact. They demonstrate a global effort to address the issues of waste management and climate change. They show an international initiative to deal with the problems of waste management and climate change. Industries and communities may promote responsible consumption and waste reduction, contribute to a cleaner, greener future, and invest in recycling equipment by embracing technology. This will ensure a more sustainable and environmentally friendly earth for future generations.

#blow moulding machine alphamac#inspection machine#injection moulding machines#blow moulding machines#moulding machine

0 notes

Text

Advancing Agriculture & Industry: A Comprehensive Guide to Modern Equipment

Introduction

In the fast-paced world of agriculture and industry, staying ahead of the curve is essential for success. Embracing modern technology and equipment is the key to boosting productivity, efficiency, and overall profitability. In this blog, we will explore the significance of agricultural and industrial equipment and how it is revolutionizing these sectors.

The Evolution of Agriculture and Industrial Equipment

Over the years, agriculture and industry have witnessed a remarkable transformation due to technological advancements. Gone are the days of manual labor and traditional tools; today, sophisticated equipment has taken center stage. From state-of-the-art crop shredders, power weeders, and chaff cutters in agriculture to high-end oil expeller machines and thermal fogging equipment in industry, innovation has revolutionized the way we work.

Advantages of Modern Equipment

The adoption of modern equipment offers numerous advantages. Improved efficiency and reduced labor costs are just the tip of the iceberg. Advanced equipment allows for precise control, minimizing wastage and maximizing output. It also ensures better quality end-products, increasing customer satisfaction and enhancing the brand's reputation.

Empowering Farmers for a Bountiful Harvest

Agricultural equipment like power weeders, brush cutters, and winnower machines have empowered farmers to take on challenges with confidence. Crop yield has significantly increased, and the time and effort required for various farming activities have reduced drastically. Additionally, access to essential raw materials like fertilizers and cattle feed machines further optimizes farming practices.

Driving Industrial Growth and Efficiency

In the industrial landscape, the significance of modern equipment cannot be overstated. Industries can now streamline their processes with oil expeller machines, agarbatti making machines, and paper plate machines, to name a few. These advancements lead to faster production cycles, reduced costs, and a more sustainable approach to resource consumption.

Sustainability and Environment-Friendly Practices

With the world becoming increasingly environmentally conscious, the integration of eco-friendly equipment is a major step forward. Water softeners and thermal fogging machines play crucial roles in conserving resources and controlling pollution levels. As industries strive for greener alternatives, the demand for environmentally friendly equipment continues to grow.

DASP Mart: Your One-Stop Solution

To embrace the full potential of modern equipment, look no further than DASP Mart. As a leading Agricultural and Industrial Equipment Manufacturer, DASP Mart offers an extensive range of top-quality products. From crop shredders and chaff cutters to oil expeller machines and cattle feed machines, we cater to the diverse needs of farmers and businesses alike.

Conclusion

In conclusion, the integration of cutting-edge agricultural and industrial equipment has ushered in a new era of progress and prosperity. With increased efficiency, improved productivity, and a focus on sustainability, these sectors are poised for a bright future. Embrace the power of modern equipment today and take your agriculture or industry venture to new heights with DASP Mart at your side. Let innovation lead the way as we shape a more advanced and promising tomorrow.

1 note

·

View note

Text

Custom Small Double Shaft Toy Waste Shredder Manufacturer & Supplier In China - OuKe

Toys turn into waste when they got broken, faded, distorted, and dirty or replaced by new toys. 90 percent of the toys are made of plastic, others are made of fabric, paper, metal, wood, rubber or clay. Hence, toy waste shredder machines should be able to deal with these materials.

OuKe Small Dual Shaft Toy Waste Shredder is an ideal equipment to do the shredding work.

If this small twin-shaft toy shredder machine is not perfect for your application, just tell us your specific information about the toys you deal with including the size and materials. OKMI dual shaft shredder experts will get back to you with the best shredding solution!

Or if you want a customized toy waste shredder, you are lucky to find OuKe. As we provide superior custom service!

Maanshan OuKe heavy industry machinery manufacturing co.,LTD, a collection of scientific and technological research and production company, specialize in shredder machine, import and export business, the professional manufacturer. Our main products: shredder machine, Double shaft shredder, kitchen waste shredder, small shredder, metal shredder, rubber and tire shredder, plastic shredder, wood shredder, cans shredder, cars shredder, woven bag shredder, film shredder, crusher etc.For more details about Double Shaft Toy Waste Shredder, https://www.okshredder.com/

0 notes

Text

Shredding Machine in Chennai India at Avanti-ltd

Electronic Waste Shredders Manufacturers in Tamil Nadu Avanti-ltd is offering high quality of shredding machines. If you are thinking to buy Shredding Machine in Chennai or Shredding Machine in Hyderabad contact us at Web: - https://www.avanti-ltd.com/

0 notes

Text

Types of Businesses That Use Shredding Services

Businesses and organizations of all sizes and sectors widely use on-site and off-site shredding services. Shredding helps dispose of their sensitive and confidential data securely.

If you are unsure whether or not you should try these professional services, here we quickly enlist the different types of businesses that commonly utilize paper shredding in Clearwater and around:

Accounting firms and financial services providers

Advertising and marketing agencies

Automotive dealerships and repair shops

Construction companies and contractors

Consulting firms and professional service providers

Educational institutions (schools, colleges, and universities)

Energy and utility companies

Financial institutions (banks, credit unions, and investment firms)

Government agencies and departments

Healthcare facilities (hospitals, clinics, and medical practices)

Hospitality industry (hotels, resorts, and restaurants)

Insurance companies

Law firms and legal professionals

Manufacturing and industrial businesses

Media and entertainment companies

Non-profit organizations

Real estate agencies and property management companies

Retailers and e-commerce companies

Technology firms and IT service providers

Transportation and logistics companies

These are just a few examples; many other industries and organizations can benefit from expert Sarasota, Clearwater, and St. Petersburg Paper Shredding services (essentially anywhere in Florida)to protect sensitive information and maintain data security.

However, when it comes to shredding confidential documents, there are several key factors to remember. Here are some important considerations:

Legal and Regulatory Requirements

Different industries may have specific legal and regulatory requirements for handling and destroying confidential data. Understand and comply with these rules to avoid any legal ramifications.

Document Classification and Retention Policies

Establish a document classification system that determines which documents are considered confidential and need to be shredded. Additionally, implement retention policies that specify how long certain documents should be retained before shredding.

Secure Storage

Safely store confidential records until they can be shredded. It may involve using locked cabinets, off-site storage with authorized personnel, and restricting access.

Shredding Equipment

Choose a service provider using reliable shredding equipment that meets your specific needs. It must be of industrial-grade quality to ensure a hassle-free process.

Destruction Method

Determine the most appropriate shredding method for your documents. Cross-cut and micro-cut shredders offer the highest security, slicing documents into confetti-like pieces which are difficult to reconstruct. Alternatively, consider professional services for a safe and efficienton-site or off-site shredding job.

Employee Training

Educate employees about the importance of document security and proper shredding practices. Train them on effectively identifying confidential documents, handling them securely, and using in-house shredding equipment.

Chain of Custody

From collection to destruction, maintain a documented chain of custody for confidential documents. It can help track and verify that the documents were correctly handled and shredded.

Destruction Certificate

Request the Certificate of Destruction from your Clearwater or St. Petersburg Paper Shredding service provider as proof that your materials were properly destroyed.

Environmental Considerations

Look for services that have environmentally responsible practices. Eco-friendly document destruction and recycling must be your go-to consideration.

The Key Takeaway

Now that you know which businesses must shred and how to choose the best service provider, we hope it helps you make empowering and informed decisions for the safety of your sensitive data.

0 notes

Text

Industrial Shredders Market Global industry share, growth, drivers, emerging technologies, and forecast research report 2030

The latest market report published by Credence Research, Inc. “Global Industrial Shredders Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global industrial shredder market has witnessed steady growth in recent years and is expected to continue growing at a CAGR of 5.10% between 2023 and 2030. The market was valued at USD 1154.9 million in 2022 and is expected to reach USD 1635.9 million in 2030.

The global industrial shredder market is segmented by the number of shafts, position of shafts, application, price, distribution channel, and region. Single shaft shredders are the most popular type, while the vertical shaft shredder category dominates in terms of shaft position. The medium price segment holds the largest market share, and the direct distribution channel is the most common. Asia Pacific leads the market growth.

The industrial shredder market is highly competitive, with key players including Advance Hydrau-Tech Pvt. Ltd., ANDRITZ AG, BCA Industries, Brentwood Recycling Systems, ECO Green Equipment, LLC., EcoStan India Private Limited, Hammermills International, Metso Corporation, MOCO Maschinen- und Apparatebau GmbH & Co. KG, Rapid Granulator Inc., Servo International, SSI Shredding Systems, Inc., UNTHA Shredding Technology GmbH, Vecoplan AG, and WEIMA Maschinenbau GmbH. These companies focus on product innovation, expanding their distribution networks, and strategic partnerships to maintain a competitive edge.

The main drivers of the global industrial shredder market include the increasing amount of industrial waste generated by various industries and growing awareness of the financial and environmental benefits of recycling and resource recovery. However, challenges exist in the form of high initial investment costs and inadequate waste management infrastructure in some regions. Growth opportunities lie in the integration of loT technology, emerging markets, and advancements in waste management methods.

Industrial shredders market dynamics are constantly evolving due to the rise in demand for effective waste management solutions across various industries. The growth of the industrial shredders market can be attributed to several factors, including increasing awareness about environmental sustainability, stringent government regulations on waste disposal, and rising concerns over data security. Companies are investing heavily in R&D activities to develop advanced and efficient shredding technologies that cater to different applications such as paper, plastics, metals, e-waste among others. Furthermore, with an increase in automation across manufacturing and processing industries has led manufacturers of industrial shredders to integrate their equipment with smart technology for real-time monitoring and control. Moreover, the adoption of Industry 4.0 is driving the demand for intelligent shredding systems that can adapt autonomously according to changing process conditions resulting in increased productivity while reducing operating costs.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Industrial Shredders Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

In-depth analysis of the global market segmentation on the Route of Administration and Application

Major nations in each region with their import/export statistics

The global Industrial Shredders Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/industrial-shredders-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/shot-blasting-machine-market

Related Report: https://www.credenceresearch.com/report/hydrostatic-transmission-market

Browse Our Blog: https://www.linkedin.com/pulse/india-industrial-shredders-market-global-industry-share-singh

0 notes

Text

Bollegraaf Recycling Solutions

Bollegraaf Recycling Solutions is a leading global engineer and manufacturer of turnkey recycling solutions and recycling equipment. The company is renowned for its innovative and high-quality products, which are used by recycling companies all over the world.

History

Bollegraaf Recycling Solutions was founded in 1968 in the Netherlands. The company began by manufacturing balers for the recycling industry, and quickly expanded into other areas of recycling equipment manufacturing. Today, Bollegraaf Recycling Solutions offers a wide range of products, including balers, shredders, and sorting systems.

Products

Bollegraaf Recycling Solutions offers a wide range of products for the recycling industry, including:

Balers: Bollegraaf Recycling Solutions offers a wide range of balers for the recycling industry. Balers are used to compress recyclable materials, such as paper, cardboard, and plastic, into compact bales. This makes it easier and more efficient to transport and recycle these materials.

Shredders: Bollegraaf Recycling Solutions also offers a range of shredders for the recycling industry. Shredders are used to shred recyclable materials, such as wood, metal, and plastic, into smaller pieces. This makes it easier to sort and recycle these materials.

Sorting Systems: Bollegraaf Recycling Solutions also offers a range of sorting systems for the recycling industry. Sorting systems are used to separate recyclable materials from non-recyclable materials. This is an essential step in the recycling process, as it helps to ensure that recyclable materials are not contaminated with non-recyclable materials.

Services

In addition to its product offerings, Bollegraaf Recycling Solutions also offers a range of services, including:

Engineering: Bollegraaf Recycling Solutions offers engineering services to help customers design and build custom recycling solutions.

Installation: Bollegraaf Recycling Solutions offers installation services to help customers install and commission its recycling equipment.

Training: Bollegraaf Recycling Solutions offers training services to help customers learn how to operate and maintain its recycling equipment.

Parts and Service: Bollegraaf Recycling Solutions offers a comprehensive parts and service program to help customers keep its recycling equipment running smoothly.

Sustainability

Bollegraaf Recycling Solutions is committed to sustainability. The company invests heavily in research and development, and is constantly looking for new ways to improve its products and processes. Bollegraaf Recycling Solutions is also committed to using sustainable materials and practices in its manufacturing processes.

Global Presence

Bollegraaf Recycling Solutions is a global company with operations in over 50 countries. The company has a strong customer focus, and is dedicated to providing its customers with the best possible products and services.

Awards and Recognition

Bollegraaf Recycling Solutions has been recognized for its innovation and sustainability. The company has won numerous awards, including:

The Recycling International Award for Innovation

The European Recycling Award for Sustainability

The World Recycling Award for Best Recycling Equipment Manufacturer

Conclusion

Bollegraaf Recycling Solutions is a leading global provider of recycling equipment and solutions. The company is committed to innovation and sustainability, and offers a wide range of products and services to meet the needs of its customers.

0 notes

Text

How to Start a Waste Management Recycling Models Business

Introduction

In today's world, waste management and recycling have become critical issues due to the increasing amount of waste generated and the impact it has on the environment. Starting a waste management recycling model business not only addresses this concern but also presents a lucrative opportunity to contribute to sustainability while making a profit. In this blog, we will explore the key steps involved in starting a waste management recycling business.

Research and Planning

The first step towards starting any business is conducting thorough research and planning. Familiarize yourself with the waste management and recycling industry, including the latest trends, regulations, and technologies. Identify the specific type of waste you want to focus on, such as plastic, paper, electronic waste, or organic waste. Determine your target market and understand the demand for recycling services in your area.

Develop a comprehensive business plan that outlines your goals, target market, competition analysis, marketing strategies, financial projections, and operational requirements. A well-structured plan will serve as a roadmap for your business and help attract potential investors or secure funding.

Legal and Regulatory Compliance

Waste management and recycling businesses must comply with various local, state, and federal regulations. Research and understand the legal requirements for waste handling, recycling, and disposal in your area. Obtain the necessary permits, licenses, and certifications required to operate legally. These may include environmental permits, waste disposal licenses, and recycling certifications.

Additionally, familiarize yourself with health and safety regulations to ensure a secure working environment for you and your employees. Establish proper protocols for waste collection, transportation, and processing to prevent any health hazards.

Infrastructure and Equipment

Invest in the necessary infrastructure and equipment to facilitate your waste management and recycling operations. This may include a sorting facility, storage area, transportation vehicles, shredders, compactors, balers, and recycling machinery specific to the type of waste you are handling. Consider both the initial investment and ongoing maintenance costs when selecting your equipment.

Furthermore, ensure that your facility meets the required safety and environmental standards. Implement appropriate waste segregation and storage systems to prevent contamination and maximize the efficiency of recycling processes.

Collaboration and Partnerships

Building strong collaborations and partnerships is vital for the success of your waste management and recycling business. Establish connections with local waste generators, such as households, businesses, schools, and industrial facilities. Offer them cost-effective and convenient waste collection and recycling services. Develop mutually beneficial relationships with suppliers of recycled materials, such as manufacturers or construction companies, who can utilize your products.

Collaborate with local authorities, environmental organizations, and recycling industry associations. These partnerships can provide you with valuable insights, resources, and networking opportunities. Stay updated on industry events, conferences, and trade shows to expand your knowledge and establish contacts within the waste management and recycling sector.

Marketing and Awareness

Effectively marketing your waste management recycling models business is crucial to attracting customers and creating awareness about your services. Develop a strong brand identity and create a professional website that showcases your company's mission, services, and environmental impact. Utilize social media platforms to engage with your target audience, share educational content about recycling, and promote your business.

Offer educational programs, workshops, and seminars to raise awareness about the importance of waste management and recycling within your community. Participate in local events, collaborate with schools, and engage in public outreach initiatives to foster a sense of environmental responsibility.

Conclusion

Starting a waste management recycling model business requires careful planning, compliance with regulations, infrastructure investment, collaborations, and effective marketing. By implementing these key steps, you can establish a successful and sustainable business that contributes to waste reduction, resource conservation, and environmental protection. Remember, waste management and recycling are essential components of a greener and more sustainable future.

0 notes

Text

Rotary Shear/Pre Shredder/Twin Shaft Shredder

The rotary shear also known as twin-shaft shredder designed for low-speed, high-torque operation. These dual-shaft shredders are well-suited to stand alone operation or can be used for pre-shredding for further downstream processing. This scrap processing machine mainly used to shred /shear large items like domestic, commercial, and bulky waste. The scrap like cable drums, building blocks, metal sheet, car body, car door, as well foils, paper, and textiles, transforming them into smaller pieces. Additionally, it efficiently handles high-volume input materials and heavy parts. The rotary shear consistently delivers outstanding shredding performance. Advance Hydrau-Tech known for manufacturing high quality scrap processing machines and India's leading manufacturer of balers, shears, shredders, and briquetting machines. Our Pre Shredder, Rotary Shear is widely acclaimed in the recycling industry for its exceptional performance.

0 notes

Text

What Are The Rules Of Paper Shredding?

The rules of paper shredding may vary depending on your specific situation. But here are some general guidelines for you to follow:

Determine What Needs To Be Shredded

Identify the types of business documents that require shredding. For example, you must shred any document containing personal or sensitive information, such as your social security number, credit card numbers, bank statements, medical records, insurance papers, employee pay stubs, visitor logs, or other identifying information.

Use a Shredder That Meets Your Needs

Choose an office shredder that meets your specific needs. The different types include strip-cut, cross-cut, and micro-cut shredders that offer varying levels of security. Pick the one that’s the safest, or go for professional services for better assistance. Google “shredding services near me” and get started with a certified company.

Prepare the Documents

Before shredding on-site with your office equipment, remove any staples, paperclips, or other fasteners from the documents. This will help prevent jams and extend the life of your shredder. But you can effectively eliminate this stress when you partner with pros. So choose your options wisely.

Feed the Documents into the Shredder

Feed the documents into the shredder in small batches, following the manufacturer’s instructions. Don’t overload the shredder, as this can cause jams. When you call in professionals, they collect your confidential waste and feed it to their industrial shredders, mixing materials with other loads for enhanced data safety.

As a general rule of thumb, you must destroy pay stubs, bank records, and medical papers within a year of payment. Shred tax records after seven years. Any identity records like birth certificates, driver’s licenses, or passports can be shredded after expiry. Any bills, warranty papers, junk mail, etc., can be shredded immediately.

Dispose Of Shredded Paper Properly

After shredding in-house, dispose of the shredded paper properly. You can recycle or dispose of the shredded paper in a secure trash bin. If you wish to avoid adding the stress of disposal, hiring experts is a good option as they can take over these tasks, and you can proceed with other essential business stuff.

Consider Shredding Services

If you have many documents that need to be shredded or don’t have access to a high-quality office shredder, consider using a professional shredding service. Look up “paper shredding near me” and understand your options.

Final Words

Remember, shredding sensitive documents is essential in protecting confidential information from falling into the wrong hands. Choose your options wisely!

0 notes