#High Quality Effect Pigments for Plastic

Text

UV Masterbatches: Importance and benefits

In this business-centric blog, we are going to highlight UV Stabilizer masterbatch, and why, and how it has become an integral part of the plastic industry. Also, our focus will remain on UV master batch manufacturer.

Before we take deep dive into the subject, it makes sense to learn about masterbatches.

What is a masterbatch?

Masterbatch is a solid additive engineered for plastic. It is designed for adding color to plastic-made items. At the same time, the product imparts a wide range of properties to plastics. The latter is called additive masterbatches. It is a concentrated mixture of pigments or additives. Which is encapsulated during a heat process into a carrier resin. This mixture is then cooled and cut into a granular shape.

For in-depth knowledge about the product, you can connect with a leading masterbatch manufacturer in India, Ahmedabad.

Unique features of masterbatch

Plenty of unique features make this product suitable for the plastic industry. Here are a few important qualities of masterbatches that make them ideal for various items made using plastic:

High jets

No Issues of bleed or bloom

Easy to process

UV stability

Uniform dispersion

Resistant to high-temperature

Learning about the UV Stabilizer masterbatch

Exposure to sunlight and some artificial lights can have adverse effects on the useful life of plastic products. UV radiation can break down the chemical bonds in a polymer. This process is called photodegradation. It ultimately causes cracking, chalking, color changes, and the loss of physical properties. To counteract the damaging effect of UV light, UV stabilizers masterbatch are used to solve the degradation problems associated with exposure to sunlight. In case, you have any doubt, regarding the product, you can connect with a prominent UV master batch manufacturer, UV master batch supplier, like Sumiran Masterbatches.

Properties of a quality-driven UV Stabilizer masterbatch

1% to 5% loading with polymers for better result

High resistance to extraction

Long-Term UV Resistance

Excellent surface characteristic

Applications

UV Stabilizer masterbatch has found usages in numerous applications, given its properties and salient features. These include:

Agricultural greenhouse film, FIBC bags, moulded crates, drums, garbage cans, garden furniture, outdoor articles etc…

Tarpualin, Roto moulded Water Tank

Shaded Net

Woven sacks, HDPE/PP raffia tapes, LDPE/LLDPE/PP lamination.

All types of PP/PE made products.

Industries drawing benefits from the brilliant additive

Over the years, masterbatch technology has evolved a lot, enabling UV master batch manufacturer and UV master batch supplier to manufacture quality-driven products. Numerous industries are drawing benefits from the product. These include:

Agriculture

Lamination

Packaging

FMCG (Fast Moving Consumer Goods)

Custom-made masterbatches

Prominent UV masterbatch manufacturer in India holds the expertise to deliver custom-designed solutions. Their team of engineers and technicians has the rich professional experience to manufacture masterbatches and additive masterbatches according to the requirements of clients.

About Sumiran Masterbatch

We are a professionally managed company with more than 25 years of experience as a leading manufacturer and supplier of a wide range of masterbatches and additives, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others. Our product range is known for optimized performance and efficiency.

Are you searching for masterbatches for your plastic industry? End your search with Sumiran Masterbatch. Why go further?

8 notes

·

View notes

Text

White Masterbatch Manufacturer in India

White masterbatch is a highly sought-after type of plastic additive that is used to impart a bright and consistent white color to various plastic products. It is typically used in the production of plastic goods that require a white base, such as packaging materials, consumer goods, and automotive parts.

So, what exactly is a white masterbatch? Simply put, it is a concentrated mixture of titanium dioxide (TiO2) and a carrier resin, such as polyethylene (PE) or polypropylene (PP). The TiO2 pigment is added to the carrier resin in high concentrations, resulting in a masterbatch that can be added to plastic products during the manufacturing process to achieve a uniform and opaque white color.

There are several benefits to using white masterbatch in plastic production. For one, it offers a cost-effective alternative to producing white plastic products, as it eliminates the need for manufacturers to purchase expensive pre-colored resins. Additionally, it allows for greater flexibility and control in the manufacturing process, as it can be added to plastic products in varying concentrations to achieve the desired shade of white.

White masterbatch is also highly customizable, as it can be formulated with other additives to achieve specific properties, such as UV resistance, flame retardancy, and antistatic properties. This makes it an ideal additive for a wide range of plastic applications, from food packaging to automotive parts.

However, it is important to note that not all white masterbatch products are created equal. The quality of the masterbatch can vary greatly depending on the manufacturing process and the quality of the raw materials used. For this reason, it is important to work with a reputable supplier who can provide high-quality white masterbatch products that are tailored to the specific needs of your application.

In conclusion, white masterbatch is a valuable additive in the plastic industry that offers a cost-effective and customizable solution for achieving a bright and consistent white color in plastic products. By working with a trusted supplier, manufacturers can ensure that they are using high-quality white masterbatch products that meet their specific requirements and standards.

3 notes

·

View notes

Text

Best Home Interior ideas: How to Choose Paint Finishes For Your Home

Essential Guide to Paint

Paint is your passport to color and arguably the easiest, least costly and most immediate way to transform a home. It can be as simple as brilliant white, but that would exclude all the other drop-dead gorgeous colors. Paradoxically, it’s the vast choice that often poses a problem — there are just so many brands, types and shades on the market.

Choose from historical hues for period homes; sleek chalky finishes that stand up to the rigors of modern life; or new formulas designed to suit all surfaces. By understanding the product you can unleash all the design possibilities of paint that make it such a tempting medium.

Types of Paint

Water-based paints are usually referred to as emulsions and were traditionally used only for interior walls and ceilings. But recently tremendous advances in paint technology mean that water-based formulas, especially the high-performing acrylics, are available for all surfaces, from woodwork to metal, and for interior and exterior use. The advantages of these paints over oil-based ones are that they are cleaner, have fewer odors and are more environmentally sound. Brushes can be rinsed clean with water.

Solvent or oil-based paints are used where a tough, durable finish is required for interior and exterior timber, masonry and furniture — although, as mentioned above, the new generation of acrylics and multi-surface paints offers viable alternatives. In general, brushes need to be cleaned with turpentine or white spirit.

Make-up and quality all paints are made of four key ingredients: pigments, binders, liquids and additives. Generally speaking, the more pigment used to make the paint, the better the quality it will be: a ratio of 30 to 45 per cent binder and pigments by volume indicates a paint that will be durable and provide good coverage and lasting color. Consider the following when you are faced with a wall of paint pots and are struggling with what to buy.

Pick a brand you can trust Companies with their own high-street shops, such as Fired Earth and Farrow & Ball, and those that sell through the DIY giants are the most accessible. However, buying paint online is increasingly popular and can bring you a wider choice, especially if you live outside major towns and cities.

Go for good coverage Look at the figures per liter not for the whole can; 12sq m per liter is average. Cover ability varies between brands, making the difference between needing two or three coats. You will generally find more pigment in premium paints, giving a greater depth of color.

Select the right product. There is a dedicated paint for practically every surface, including tiles and appliances, such as fridges. For high-traffic areas consider scuff-resistant multi-surface paints that can be used on both wood and walls. Kitchens and bathrooms benefit from specialist formulas designed to cope with humidity without flaking.

Try before you buy Color cards are fine for making an initial selection but you will want to see a true paint sample in situ before committing. Tester pots vary in price from £1 to £4. Paint onto a sheet of paper that you can move around the room to enable you to see the color in different light conditions. The effect varies greatly. The window wall can seem dark while the wall opposite will be flooded with light. And of course there is a dramatic difference between natural and artificial light. Finally paint a patch directly onto the wall to gauge the color, coverage and the final finish.

Specialist wall, floor and furniture paints

These days, there are paints to decorate every surface in the home, from melamine to ceramic tiles. Many of these formulas require no specialist preparation — Crown’s Cupboard Makeover Paint is available in 12 colors and does not need a primer.

There are also multi-surface paints, such as B&Q Colors Everywhere for walls, ceilings, woodwork and radiators, and Bedec MSP Multi Surface Paint, which can be used on everything from plastic to masonry. Areas such as bathrooms and kitchens benefit from durable, mildew-resistant coverings, which are available in premixed colors.

However, for the more discerning, Deluxe Kitchen & Bathroom paint can be mixed in any one of its 1,200 colors, and Farrow & Ball is launching Modern Emulsion. Designed to complement its original Estate Emulsion, the paint has a slightly higher sheen, is fully washable and available in the full color range.

Specialist paints also include some exciting new finishes, such as suede effects, metallic’s and high-sheen lacquers. Judy Smith, color consultant at Crown, suggests an accent wall in one of these to lift a neutral scheme. Crown’s Feature Wall range, which includes eight metallic finishes, nine bright colors and a highly reflective Pure Brilliant White, comes in convenient 1.25 liter tins.

If you have a timber floor that’s not particularly attractive or is made from a patchwork of old and new wood, paint makes the perfect disguise. There are plenty of choices — all the colors from Farrow & Ball are available as floor paint and Nordic decor Style offers an elegant selection, too.

Alternatively, a timber floor in good condition can be treated to a natural or tinted stain, which allows the grain to show through. Eve Johnson’s Scandinavian wood care oils will take the yellow edge off pine.

If you are grappling with the problem of choosing a woodwork color to go with neutral walls, check out Architectural Colors by David Oliver, the founder of Paint & Paper Library. He arranged his off-whites for ceilings, cornices, walls and woodwork in chromatically groups and the concept has been so well received that chromatically arranged colors, such as soft grays, greens and pinks, have been introduced.

Exterior Masonry and Woodwork Paints

Specialist masonry and exterior woodwork paints are now available in many of the sophisticated colors offered for interiors. For example, the new Weather shield range of satin and gloss exterior paints from deluxe features innovative shades such as Wild Berries and Wild Roses.

When choosing colors for exterior surfaces, consider the style of the brickwork or masonry of your home along with the colors used on nearby buildings, so as to pick colors that are sympathetic to these surroundings. Colors for fences and sheds should be selected with the same criteria in mind.

Technical advancements are constantly being made to improve the life span, durability, wear and performance of exterior paints. Masonry paints come in a wide variety of finishes, from textured to ultra-smooth. Opt for a texture if you need to disguise fine surface cracks. If you favor traditional finishes, then consider lime wash, which is available from specialists such as Francesca’s LimeWash. The beauty of this paint is that it will mellow and weather with time. However, do check with the supplier first to ensure that the surface is suitable for this finish.

Traditional Paints

Available from specialists such as Farrow & Ball and The Real Paint & Varnish Company, lime wash and distemper paints can be useful for restoration projects, although some of the contents are potentially hazardous and can irritate eyes and skin. Use the modern equivalents where possible, as these are usually safer and more effective.

Cutting Down on Paint Chemicals

Everyone knows the nasty smell of paint drying — worse with oil-based paints, but also noticeable with vinyl emulsions. This is caused by paint solvents containing VOCs. They are proven health risks, and can cause allergies, headaches and breathing problems and irritate eyes, nose and throat. They are also an environmental hazard.

Following a European directive, the British paint industry has reduced VOCs in two stages, the second of which came into force in January last year.

Five categories are used to describe VOC content. For guidance, a minimal VOC content is up to 0.29 per cent, whereas a very high VOC content is above 50 per cent. All brands have, where necessary, reformulated their ranges to give minimal VOC content.

There is still no standard labeling scheme for paint. The blue globe label, pioneered by B&Q, led to VOC reduction on the mass market and has been adopted by other brands, while the European Ecolabel, recognised in 15 EU member states, looks like a flower and appears on brands such as Earthborn. Germany also has a Blue Angel label and there is a green Nordic style interior design Swan as well. You will find more detailed information on most of the paint company’s websites, as well as a wealth of practical and design advice.

Ecological Paint

The “organic” paint brands, such as Ecos, which emerged in the late 1980s, heralded a new era of odorless paints, free of solvents and VOCs (volatile organic compounds) and paved the way for other companies’ environmentally safe formulas. Following European legislation, the first stage in lowering the solvent content in paints and varnishes is set to come into force in 2007.

Traditionally, the solvents or VOCs and other chemicals used to make paints easier to apply give off toxic fumes that seep into the atmosphere for years after application. Paints with reduced or no VOCs are healthier for decorators and the people whose homes are painted with them.

The leading brands now flag up paints with lower VOCs and produce paints that are virtually odor-free — the Breatheasy range by Crown is one example. Most leading brands now produce high-quality water-based acrylic paints which outperform the older technologies of vinyl and oils.

Today, it is increasingly easy to source ecologically sound paints, as most specialist ranges, such as Ecos, Earthborn, Georgina Barrow and Auro are available via mail order. There is a wealth of color options in these pre-mixed ranges that include lush shades and muted palettes, reflecting their natural ingredients. Ecos continues to lead the field. It has recently developed Atmosphere Purifying Paint, which absorbs and neutralizes volatile chemicals, solvents and VOCs from the atmosphere in a home.

Get Expert Paint Colour Advice

Thousands of shades may offer unparalleled choice, but of course it can be harder to pinpoint the right one for you. Dulux has responded with the Tailor Made range, which offers an easy-to-use color-scheming chart that works with the 1,200 shades available to mix in-store.

Paint & Paper Library arranges its colors in five shades from light to dark to help select coordinating colors for ceilings, cornices, walls, doors and woodwork. If you are decorating around bold furnishings, such as a sofa or curtains, look at paint colors from the same fabric house as they are most likely to be sympathetic.

Malabar and Designers Guild offer some striking brights while the new Shades of Sanderson comprises 120 colors tailored to Sanderson’s collections. If you are aiming for a more subtle backdrop that will flow through several rooms, it’s wise to stick to neutral shades including Nordic style living room. Kevin McCloud’s Elements of Color for Fired Earth works especially well with our cool, northern light.

Paint Glossary

Distemper — A traditional water-based paint made from animal and natural resins, which dries to a velvety matt finish. Primarily used on ceilings and plaster moldings, and to give furniture an aged effect, but not suitable for areas of high wear. Available to order from specialist companies.

Eggshell — Traditionally refers to an oil-based paint with a silky finish, suitable for interior walls and woodwork. Water-based alternatives are now available.

Flat or Dead-Flat Oil — Provides a completely flat, oil-based finish. Generally used on walls but not suitable for areas of high wear.

Gloss — These paints have a high sheen level and are usually used on woodwork.

Limewash — Made from slaked lime and water, this paint is good for porous surfaces such as brickwork, render and plaster and gives a chalky finish. It is available from specialist companies.

Matt — Describes paints that give a flat, non-reflective finish. It is ideal for walls and ceilings that are not perfectly smooth.

Satin or silk — Water-based vinyl or acrylic paint for walls in high-wear areas, such as hallways and kitchens. A satin finish will be slightly shinier than silk.

Satinwood or semi-gloss — These paints are commonly used on woodwork, such as skirting boards. This sheen level is between eggshell and gloss.

You can find more information on paint and paint finishes and interior design ideas at Home Interior ideas.

2 notes

·

View notes

Text

Chromatic Brilliance: BS Masterbatch Elevating Products with Color Masterbatches

In the world of plastics manufacturing, color masterbatches serve as the palette with which manufacturers create products that captivate, inspire, and differentiate. Among the leading providers of color masterbatches, BS Masterbatch shines as a beacon of excellence, offering a diverse array of solutions crafted with precision, innovation, and expertise. Let's embark on a journey to explore the artistry and ingenuity behind BS Masterbatch's color masterbatches and their transformative impact on the world of plastics.

The Art of Color: Color is more than just a visual attribute; it is a language that evokes emotion, communicates identity, and enhances functionality. Recognizing the power of color as a design element, BS Masterbatch approaches color masterbatch manufacturing as a form of art, blending science and creativity to produce hues that resonate with customers and consumers alike. Whether it's a bold, vibrant shade for packaging, a subtle, sophisticated tone for automotive interiors, or a custom color match for brand consistency, BS Masterbatch's color masterbatches are meticulously crafted to achieve the desired aesthetic impact.

Precision and Consistency: Consistency is key in color masterbatch manufacturing, and BS Masterbatch excels in delivering products that meet the highest standards of precision and reliability. Through rigorous quality control measures and advanced manufacturing techniques, BS Masterbatch ensures that every batch of color masterbatch maintains uniformity in color, dispersion, and performance. Whether it's a small-scale prototype or a large-scale production run, customers can trust that BS Masterbatch's color masterbatches will deliver consistent results, batch after batch.

Customization and Flexibility: BS Masterbatch understands that one size does not fit all when it comes to color masterbatches, and that's why the company offers a high degree of customization and flexibility to meet the unique needs of its customers. From adjusting color shades and opacity levels to incorporating special effects and finishes, BS Masterbatch collaborates closely with customers to develop bespoke color masterbatch formulations tailored to their specific requirements and objectives. This level of customization not only ensures that customers achieve their desired aesthetic vision but also fosters a collaborative partnership based on mutual trust and understanding.

Innovation and Technology: Innovation is at the heart of BS Masterbatch's approach to color masterbatch manufacturing, driving the company to explore new technologies, materials, and processes to push the boundaries of what is possible. Whether it's incorporating advanced pigments and dyes for enhanced color vibrancy, developing eco-friendly formulations with minimal environmental impact, or optimizing production techniques for greater efficiency and cost-effectiveness, BS Masterbatch's commitment to innovation ensures that its color masterbatches remain at the forefront of the industry.

Application Versatility: BS Masterbatch's color masterbatches find applications across a wide range of industries and products, from packaging and consumer goods to automotive and electronics. Whether customers require color masterbatches for injection molding, blow molding, or film extrusion applications, BS Masterbatch's formulations are engineered to excel in diverse manufacturing processes and environments. Moreover, BS Masterbatch's color masterbatches offer excellent heat stability, lightfastness, and weatherability, making them suitable for both indoor and outdoor applications where durability and performance are paramount.

Sustainability and Environmental Responsibility: As a responsible corporate citizen, BS Masterbatch is committed to sustainability and environmental stewardship in its color masterbatch manufacturing operations. The company actively seeks to minimize its environmental footprint by incorporating recycled materials, reducing waste generation, and optimizing energy usage in its production processes. Moreover, BS Masterbatch offers eco-friendly color masterbatch formulations that comply with regulatory standards and support customers' sustainability goals, helping to create a more sustainable future for the plastics industry.

In conclusion, BS Masterbatch's color masterbatches represent the perfect fusion of artistry, precision, innovation, and sustainability, empowering manufacturers to bring their creative visions to life with brilliance and clarity. With a commitment to quality, customization, and environmental responsibility, BS Masterbatch continues to redefine the standards of excellence in the color masterbatch industry, driving progress and innovation in the world of plastics. As the demand for vibrant, versatile color solutions continues to grow, BS Masterbatch remains poised to lead the way, inspiring creativity and transforming products across industries and markets.

0 notes

Text

Discover the Bold Brilliance of Dark Green Metal Flake Paint

Are you looking to give your car, motorcycle, or craft project a stunning new look that turns heads and stands out from the crowd? Look no further than the eye-catching allure of Dark Green Metal Flake Paint from Flake Hub. This dazzling paint option brings a unique combination of sophistication and sparkle that can transform any surface into a masterpiece.

Unleash the Power of Sparkle

Dark Green Metal Flake Paint is more than just a color; it’s an experience. The deep, rich green hue is infused with metallic flakes that catch the light and shimmer brilliantly, creating a dynamic, multi-dimensional effect. Whether you're cruising down the highway, showing off at a car meet, or adding flair to your DIY projects, this paint ensures you make a lasting impression.

Perfect for Automotive Enthusiasts

For car enthusiasts, the exterior finish is a crucial element that speaks volumes about the vehicle’s personality. Dark Green Metal Flake Paint provides a perfect blend of elegance and boldness. The dark green base exudes a classic, refined vibe, while the metal flakes add a modern, high-energy twist. This paint is ideal for custom cars, muscle cars, motorcycles, and even bicycles, offering a show-stopping look that's both timeless and contemporary.

Quality You Can Trust

At Flake Hub, we understand that quality is paramount. Our Dark Green Metal Flake Paint is formulated using premium-grade pigments and resins to ensure long-lasting durability and a flawless finish. It’s resistant to fading, chipping, and weathering, meaning your vehicle or project will maintain its stunning appearance for years to come.

Versatile and Easy to Apply

Not only is this paint visually striking, but it’s also incredibly versatile. Suitable for metal, plastic, wood, and fiberglass surfaces, Dark Green Metal Flake Paint opens up a world of creative possibilities. Plus, with its easy application process, both professionals and hobbyists can achieve a smooth, even coat. Our detailed instructions and support resources make the painting process straightforward, ensuring you achieve professional results every time.

Elevate Your Projects

Beyond automotive uses, Dark Green Metal Flake Paint is perfect for a variety of creative projects. Whether you're customizing a guitar, crafting unique home decor, or working on model kits, this paint provides a bold, vibrant finish that enhances your creations. The metallic flakes catch the light beautifully, adding a touch of magic to whatever you’re working on.

Environmentally Conscious

We’re committed to offering products that are not only high-quality but also environmentally friendly. Our Dark Green Metal Flake Paint is formulated to minimize environmental impact without compromising on performance. It’s a choice you can feel good about, knowing you’re using a product that’s safer for you and the planet.

Join the Flake Hub Community

When you choose Flake Hub, you’re not just purchasing paint; you’re joining a community of passionate creators and enthusiasts. We offer a wealth of resources, including tutorials, tips, and inspiration to help you get the most out of your Dark Green Metal Flake Paint. Share your projects, get feedback, and connect with others who share your passion for creativity and craftsmanship.

Ready to Transform Your Project?

Don’t settle for ordinary when you can have extraordinary. Elevate your vehicle or craft project with the mesmerizing shine and depth of Dark Green Metal Flake Paint. Visit Flake Hub today to explore our full range of metal flake paints and get started on your next masterpiece.

Unleash your creativity. Embrace the sparkle. Choose Flake Hub.

#dark green metal flake paint#metal flake paint#fire red metal flake#gold metal flake#pink metal flake#metal flake gold#metal flake for sale#copper metal flake

0 notes

Text

The Versatile World of Polyethylene Wax

The Versatile World of Polyethylene Wax

In the realm of industrial applications, few materials boast the versatility and efficiency of Polyethylene Wax (PE Wax). This synthetic wax is derived from the polymerization of ethylene, a process that can be tailored to produce waxes with specific molecular weights and properties. The result is a material with a wide range of uses, from acting as a dispersant in coatings to serving as a slip agent in plastics.Get more news about Polyethylene Wax,you can vist our website!

Production and Properties

PE Wax is produced through several methods, including direct polymerization, thermal decomposition, and separation from high molecular weight polyethylene. Each method yields a wax with unique characteristics, but all share common traits such as high melting points and excellent thermal stability. These waxes are also known for their hardness and low solubility in various solvents, making them ideal for high-performance applications.

Applications Galore

The applications of PE Wax are as diverse as its production methods. In the plastics industry, it is used as a lubricant additive, particularly in the manufacturing of PVC pipes, where it enhances the flow of the material and extends the life of the processing equipment. Its role as a mold release agent cannot be overstated, ensuring that products come out clean and with the desired finish.

In the realm of coatings, PE Wax acts as a dispersant, aiding in the even distribution of pigments and fillers, thus improving the quality and durability of the final product. Its use in inks and adhesives is equally important, where it provides slip and resistance to scuffing.

A Safe Choice

One of the most significant advantages of PE Wax is its safety profile. As an oxidized product, it is authorized in the EU for the surface treatment of fruits, indicating its non-toxic nature. This makes it a preferred choice in applications where safety is a paramount concern.

Conclusion

Polyethylene Wax stands out as a material that combines performance with safety. Its myriad of applications across various industries is a testament to its adaptability and effectiveness. As industries continue to evolve, the demand for versatile and reliable materials like PE Wax is only set to increase, solidifying its place in the future of manufacturing and processing.

0 notes

Text

Chrome Effect Spray Paint

High-quality Nitro-Acrylic resin, unique metal pigments, additives, and organic solvents make up FUNGOM gold chrome paint. extensively utilized in glass, metal, ABS plastic, surface-treated wood, and other materials. However, the metallic clear spray paint's performance system and strong paint film adhesion can provide enhanced protection features like gloss and anti-corrosion.

CHROME EFFECT SPRAY PAINT ADVANTAGES & FEATURES

1. Indoor/outdoor use

2. Brilliant metallic finish

3. Durable, corrosion-resistant

4. High build, strong hiding power, fast drying

5. Fast drying, excellent hardness and flexibility.

6. Avoid scrubbing and clashing.

Physical & Chemical Properties of Chrome Spray Paint for Plastic

Item

Standard

Remark

Resin Type

Nitro-Acrylic resin.

Pigment Type

Varies with color

Appearance

Film flat and smooth, no mechanical impurities, accord with the confirmed sample.

Eye test

Drying condition

Touch dry ≤15 minutes,

Under the temperature of 20℃

finger press dry ≤ 1 hours

Recommended Thickness

18-25µ

Volume Solid

15-25%

Specific Gravity

0.90-1.15

Circle Testing

Adhesion

≤2

Circle Testing

Hardness

≥HB

Dry after 48 hours

(Room Temperature)

Gloss

Gloss ≥80; Matt accord with the confirmed sample

60℃ gloss level, relative moisture ≤ 75%

Flexibility

≤1mm

Spraying rate

≥98%

Practical Coverage at Recommended

0.5-1 m2

DFT (assumes 15% material loss)

/can)

Dry Heat Resistance

200°F (93°C)

Flash Point

156°F (69°C)

Shelf Life

Three Years

Packaging Specifications of Chrome Effect Spray Paint

ITEM NO.

Brand

Net weight

Packing

SP-003

FUNGOM®

10oz(283g)

400ml/can, 12pcs/ctn

Benefits of Chrome Effect Spray Paint

Easy to Use

The gold chrome spray paint for metal is is easy to operate and items can be dyed Chrome quickly.

Chrome Color Effective

The Chrome color is clear and gorgeous, and good reflective effect.

Strong Durable

The chrome look spray paint is durable, corrosion-resistant,high build, strong hiding power, fast drying.

0 notes

Text

Calcium Carbonate Market Analysis: Assessing Growth Opportunities

Calcium carbonate, a ubiquitous mineral compound with diverse industrial applications, plays a pivotal role in various sectors worldwide. This blog aims to explore the global calcium carbonate market, examining key drivers, applications across industries, emerging trends, and future growth opportunities.

Understanding the Calcium Carbonate Market:

Calcium carbonate (CaCO3) is a naturally occurring mineral found in rocks, shells, and minerals. It is widely used in industries such as paper, plastics, paints and coatings, construction, pharmaceuticals, and agriculture due to its properties as a filler, pigment, pH regulator, and dietary supplement.

Market Dynamics:

Paper and Pulp Industry: Calcium carbonate is extensively used as a filler and coating pigment in the production of paper and paperboard, enhancing brightness, opacity, and printability while reducing production costs.

Plastics and Polymers: In the plastics industry, calcium carbonate serves as a filler material in PVC, polyethylene, polypropylene, and other polymers, imparting stiffness, impact resistance, and cost-effectiveness to plastic products.

Paints and Coatings: Calcium carbonate acts as a pigment and extender in paints, coatings, and adhesives, providing opacity, durability, and coverage while reducing formulation costs.

Construction Sector: Calcium carbonate finds applications in the construction industry for manufacturing cement, concrete, mortar, and as a filler in architectural coatings and sealants.

Applications Across Industries:

Paper and Pulp: Filler, coating pigment in paper production.

Plastics and Polymers: Filler in PVC, polyethylene, polypropylene.

Paints and Coatings: Pigment, extender in paints, coatings, adhesives.

Construction: Cement, concrete, architectural coatings, sealants.

Market Trends:

Growing Demand for Precipitated Calcium Carbonate (PCC): The market is witnessing increased demand for PCC due to its fine particle size, high purity, and specialized applications in paper, plastics, and coatings industries.

Shift towards Sustainable Practices: Companies are focusing on sustainable sourcing, production methods, and recycling initiatives to reduce environmental impact and meet regulatory standards, driving demand for eco-friendly calcium carbonate products.

Technological Advancements: Innovations in processing techniques, surface modification technologies, and nanotechnology applications are enhancing calcium carbonate's properties and expanding its use in high-value applications.

Future Prospects:

The global calcium carbonate market is poised for significant growth, driven by expanding applications in key industries, technological advancements, and sustainability initiatives. Investments in R&D, product innovation, and eco-friendly solutions will shape the market's trajectory in the coming years.

Conclusion:

Calcium carbonate remains a versatile and indispensable mineral compound across diverse industries, contributing to product performance, cost-efficiency, and environmental sustainability. Navigating the calcium carbonate market requires awareness of industry trends, technological developments, and sustainability requirements. With a focus on innovation, quality, and sustainable practices, the calcium carbonate market presents promising opportunities for growth and advancement in various sectors globally.

0 notes

Text

Shining Light on Titanium Dioxide: Science behind its Manufacturing and Applications

Titanium Dioxide is everywhere you look! This wonder material is the most widely used white pigment on the planet, hiding in everything from the paint on your walls to the sunscreen on your nose. But what exactly is it, and how does it find its way into so many of our everyday products?

In this blog post, we'll delve into the fascinating world of Titanium Dioxide. We'll explore its unique properties, like its high refractive index that makes things bright and white and uncover its surprising applications in everything from food coloring to cosmetics. We well be also imparting the intricate details in the manufacturing process of Titanium Dioxide.

Introduction

Titanium Dioxide (TiO2) is a widely recognized bright white substance, primarily employed as a vivid colorant across various everyday items. Beyond its common usage, it possesses numerous lesser-known attributes that render it a highly valuable ingredient in our efforts to combat climate change and mitigate skin cancer risks. TiO2, an inorganic compound utilized for nearly a century, boasts non-toxic, non-reactive, and luminous properties crucial for enhancing the whiteness and brightness of diverse materials. Notably, it stands out as one of the brightest and whitest pigments, renowned for its reflective abilities and its capacity to both scatter and absorb UV rays.

Brilliant: TiO2 exhibits unparalleled brilliance, color strength, opacity, and pearlescence unmatched by any other substance. Its unique properties make it a sought-after choice for achieving vibrant and visually striking results in various applications.

Resistant: With exceptional resistance to heat, light, and weathering, TiO2 plays a vital role in preventing the degradation of paints and films, as well as the embrittlement of plastics. Its resilience ensures longevity and durability in a wide range of materials, even under harsh environmental conditions.

Protective: The ability of TiO2 to scatter and absorb UV radiation makes it an indispensable ingredient in sunscreen formulations. By effectively shielding the skin from harmful UV rays, TiO2 aids in the prevention of skin damage and reduces the risk of cancer, highlighting its crucial role in sun protection.

Powerful: TiO2 serves as a potent photocatalyst, particularly in solar panels, harnessing solar energy for various applications. Additionally, it exhibits the capability to reduce pollutants in the air, contributing to environmental remediation efforts and promoting cleaner air quality, showcasing its versatility and impact beyond traditional uses.

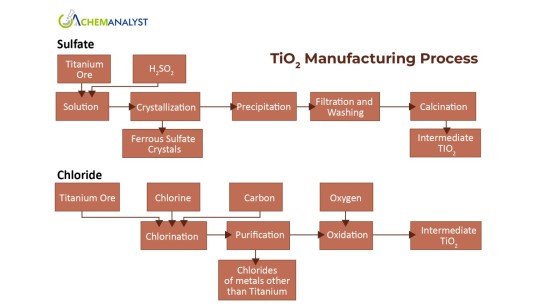

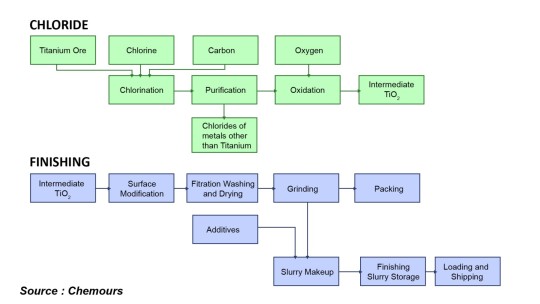

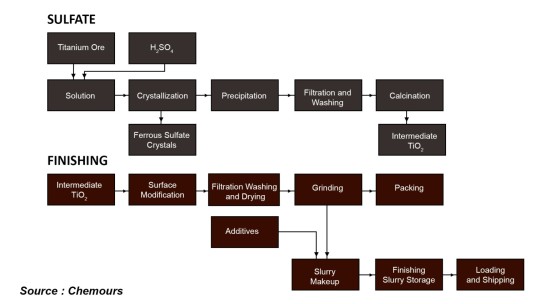

Manufacturing Process

Two primary methods, the Sulfate Process and the Chloride Process, utilize the principal ores ilmenite and rutile, respectively, for the manufacturing of Titanium Dioxide. Ilmenite typically contains 45-60% TiO2, while rutile can contain up to 99% TiO2. Although these ores are mined globally, the majority of production occurs in Australia and South Africa. Major Titanium Dioxide producers balance their production between these two processes, with both yielding the oxide in rutile crystal form. However, the Sulfate Process can also produce an alternative form, anatase, suited for specialized applications. While the Sulfate Process operates as a batch process, the Chloride Process runs continuously. Approximately 65% of the world's Titanium Dioxide production is estimated to be based on the Chloride Process.

The Chloride Process

The Chloride process commences by blending raw materials with gaseous chlorine within a fluidized bed reactor, operating at temperatures approximately between 900˚C to 1000˚C, with coke serving as a reducing agent. This process yields a gas stream comprising titanium tetrachloride (TiCl4), carbon oxides, and all impurity metals present in the feedstock in the form of metal chlorides. However, certain impurities like silica and zirconium may not undergo chlorination and consequently accumulate within the reactor.

The Chloride process for producing Titanium Dioxide involves several key steps:

Purification: The initial gas stream containing titanium tetrachloride (TiCl4) is cooled and treated to remove impurities like metal chlorides. These impurities solidify and are separated, leaving highly purified TiCl4.

Conversion: The purified TiCl4 is further cooled and condensed into a liquid state. This liquid is then fed into a high-temperature reactor (above 1500°C) where it reacts with oxygen. This reaction produces Titanium Dioxide (TiO2) and releases chlorine gas, which is recycled back to the beginning of the process.

Cleaning and Finishing: Residual chlorine clinging to the TiO2 particles is removed through a water-based process (hydrolysis). Finally, the pure TiO2 undergoes various surface treatments, milling, and drying to achieve the desired final product.

Waste Management: The chloride process generates waste products including unreacted coke and ore solids, as well as an acidic solution containing iron chloride (iron chloride waste acid). These metal chloride impurities can be harmful to the environment. Typically, they are neutralized with lime or limestone and then landfilled. In rare cases, some facilities may inject these waste salts into deep wells.

Chlorine Consumption: The amount of chlorine consumed in this process is directly tied to the iron oxide content in the raw material. More iron oxide requires more chlorine for conversion, with a portion being lost as hydrochloric acid during the process.

Reaction:

2TiO2 + 3C + 4Cl2 → 2TiCl4 + 2CO + CO2

TiCl4 (impure gas) → TiCl4 (pure liquit)

TiCl4 + O2 ➞ TiO2 + 2 Cl2

Sulfate Process

The sulphate process stands as the pioneering technology for producing Titanium Dioxide pigment commercially. In this method, ilmenite (containing 40% - 60% TiO2), titanium slag (with 72% - 85% TiO2), or a meticulously balanced mixture of both are treated with concentrated sulphuric acid (98%). The addition of carefully measured amounts of steam, water, and diluted sulphuric acid triggers a highly exothermic reaction. Lithopone, a white pigment consisting of a blend of barium sulfate (28% - 30%) and zinc sulfide (68% - 70%), alongside trace quantities of zinc oxide, is also produced through this process.

Reaction

FeTiO3 + 2H2SO4 → TiOSO4 + FeSO4 + H2O (Dissolution of the raw material)

TiOSO4 + H2O → TiO2n.H2O + H2SO4 (TiO2 precipitation)

TiO2n∙H2O → TiO2+ nH2O (TiO2 calcination and conditioning)

The resulting solution contains dissolved titanyl sulphate (TiOSO4) and iron sulphate (FeSO4) in sulphuric acid. If ilmenite is used as the feedstock, a reduction process is necessary to convert any ferric ions (Fe3+) to ferrous (Fe2+) ions, aiding in subsequent separation steps. To ensure complete iron dissolution, the solution is passed through scrap metal in an iron reduction step before clarification in a tank, allowing undissolved ore and solids to settle. The titanium solution is then concentrated and hydrolyzed to precipitate Titanium Dioxide hydrated. Filtration separates the hydrated Titanium Dioxide from ferrous sulphate and sulphuric acid. Iron sulphate is separated from the Titanium Dioxide production liquors through concentration and cooling. The hydrated Titanium Dioxide slurry undergoes calcination to grow crystals to their final size, removing residual water and H2SO4. The dried Titanium Dioxide proceeds to finishing, involving milling and potential chemical treatments like surface coating with silica or alumina. This finishing process, similar to the chloride method, includes coating, milling, and drying operations.

Major Applications of Titanium Dioxide

Cosmetics & Personal Care

In cosmetics, pigment-grade Titanium Dioxide is employed to conceal blemishes and enhance skin brightness. Its inclusion enables the application of thinner layers of makeup, achieving the desired effect with greater efficiency.

Pulp & Paper

Titanium Dioxide finds extensive use in coating paper, where its properties enhance its appearance and functionality. By incorporating Titanium Dioxide into paper coatings, manufacturers achieve a whiter, brighter, and more opaque finish. This not only enhances the visual appeal of the paper but also improves its overall quality. The Titanium Dioxide particles scatter light effectively, resulting in increased brightness and opacity. Additionally, the coating process allows for smoother printing and better ink adhesion, ensuring high-quality graphics and text. Overall, Titanium Dioxide plays a crucial role in enhancing the aesthetics and performance of paper products across various industries.

Paints & Coatings

Titanium Dioxide offers a dual benefit in paints, providing both opacity and durability. Its presence ensures that the paint effectively conceals underlying surfaces, imparting a solid, uniform appearance. Moreover, Titanium Dioxide enhances the paint's resistance to environmental factors such as UV radiation, moisture, and abrasion, thereby extending the lifespan of the painted surface. By shielding against degradation and wear, Titanium Dioxide contributes significantly to the longevity of painted structures and surfaces. This combination of opacity and durability makes Titanium Dioxide an indispensable ingredient in paint formulations, ensuring not only aesthetic appeal but also long-lasting protection for various applications.

Plastics & Rubber

Titanium Dioxide plays a crucial role in mitigating the adverse effects of light exposure on plastics and other materials. By incorporating Titanium Dioxide into their composition, manufacturers can effectively minimize brittleness, fading, and cracking caused by prolonged exposure to light. The presence of Titanium Dioxide acts as a shield, absorbing and scattering harmful UV radiation, thus reducing the degradation of the material. This protective mechanism helps preserve the structural integrity and aesthetic appearance of plastic products, prolonging their lifespan and ensuring their durability in various applications.

Market Outlook

The future growth of the Titanium Dioxide market is expected to be largely driven by the increasing demand for paints and coatings. This is because Titanium Dioxide makes paints brighter by scattering light. It also improves their hiding power (opacity) and gives them a nice shine. In fact, paints and coatings used about 40% of all Titanium Dioxide globally in 2023, and this number is expected to keep climbing. The growing need for paints and pigments in various industries, including construction, personal care, and pharmaceuticals, is another factor that will likely boost demand for Titanium Dioxide. The global Titanium Dioxide market and is expected to grow at a CAGR of 5.08% by the year 2034.

Titanium Dioxide Main Players

Major players in the Global Titanium Dioxide market are The Chemours Company, Tronox Holdings Plc, Lomon Billions Group, Venator Materials Plc, KRONOS, The Louisiana Pigment Company, LP (KRONOS-Huntsman/Tioxide JV), The Kerala Minerals & Metals Limited, Indian Rare Earths Limited (IREL), and Cochin Minerals & Rutile Ltd (CMRL), and Others.

Conclusion:

In conclusion, Titanium Dioxide (TiO2) is a versatile and valuable material with a wide range of applications beyond its well-known use as a white pigment in paints and coatings. Its light-scattering properties make it ideal for sunscreens and cosmetics, while its photocatalytic abilities offer eco-friendly solutions for pollution reduction and energy saving. From everyday products like toothpaste and food coloring to advanced applications in construction materials, TiO2 plays a significant role in our daily lives and contributes positively to both the economy and environmental well-being. Fueled by rapid urbanization, the demand for paints, coatings, and pigments is likely to rise. As a result, this surge is expected to propel the global Titanium Dioxide market forward, as its exceptional light-scattering properties (high refractive index) make it the go-to white pigment for paint and coating production.

0 notes

Text

Choosing the Right Color Measurement Device: Portable VS Benchtop Spectrophotometers (Benchtop Transmittance Spectrophotometer)

There are many different brands of color spectrophotometers on the market, and even within the same brand, there are multiple products available. The handheld and desktop types are the most popular categories, but what are the differences between these two types?

Portable Colorimeters – also known as Portable spectrophotometers

Can directly read data and connect to a computer through software: Small size, convenient to carry, high accuracy, and moderate price. Easy to operate, even ordinary personnel can easily handle it.

Desktop Colorimeters – also known as Benchtop Transmittance Spectrophotometer: Equipped with a reading window, used with color matching software when connected to a computer, has high accuracy color matching function, large size, stable function, and high price.

As we all know, Benchtop Transmittance Spectrophotometer are more accurate and consistent than portable devices. When using strict tolerances or setting color specifications, desktop devices are usually the preferred choice. Professionals working with brand colors or components of their products must match each other in the final assembly process, using desktop devices to set specifications, formulas, and quality control. On the other hand, portable colorimeters are more suitable for spot checking product quality as they are easy to carry around.

Portable VS Benchtop Spectrophotometers:

If you want to measure liquids such as orange juice, laundry detergent, or shampoo, please choose a Benchtop Transmittance Spectrophotometer; Benchtop Transmittance Spectrophotometer are also the preferred choice for setting color formulas. They are suitable for controlling fluorescence and fluorescent whitening agents in paper, textiles, plastics, pigments, and paints. Using automatic instrument settings eliminates the possibility of speculation and errors during instrument configuration.

Portable colorimeters are convenient to carry around and can be used for quality control in the laboratory. They are widely used in industries such as plastics, printing, and metal spraying for quality inspection and monitoring.

They are compact, handheld, simple, and inexpensive instruments, but still effective for specific purposes. In a Benchtop Transmittance Spectrophotometers, a specific light source (such as A or D65) illuminates the object. The reflected light passes through primary filters: red, green, and blue, which simulate the spectral sensitivity curve and reach the detector, where it provides a response proportional to the three-stimulus values. Therefore, colorimeters provide information about the amount of red, green, and blue light reflected by the object. This color information is useful for color evaluation that does not require complexity or accuracy. For example, colorimeters are very useful in production environments where measuring color differences between products and standards, or between production batches, is important. It can also be compared to color charts for evaluation purposes.

Benchtop Transmittance Spectrophotometers are more complex and accurate color evaluation devices than colorimeters. They are used for color quality control in processes that require higher accuracy, such as research labs, color formulas in paint and cosmetics companies, etc. Spectrophotometers can be handheld, with a compact and user-friendly design, suitable for industrial environments on the product line. Or they can be desktop spectrophotometers that require a more comprehensive understanding of the user, but offer greater versatility. Generally, handheld spectrophotometers or handheld measurements are used to measure opaque solid objects, while desktop spectrophotometers can be used to measure the color of opaque solids, semi-transparent solids, and liquids.

DSCD-910_Benchtop Spectrophotometer (Transmittance)

Benchtop Transmittance Spectrophotometers used for color evaluation measure the reflection or transmission radiation of the entire visible spectrum. To do this, a monochromatic radiation is used to illuminate the sample or object (spectrophotometers have monochromators, filters, or prisms that can distinguish wavelengths), and the amount of reflected or transmitted radiation is recorded.

Benchtop Transmittance Spectrophotometers are very common instruments used in color measurement. They are widely used in areas such as color evaluation, color control, color matching, and material composition analysis. As a precision instrument for color measurement, its working principle is to use a spectrophotometer to display the ratio of the spectral composition and diffraction curve of a graph and calculate the measured value accordingly. It automatically records the data measured by the spectrophotometer, and then calculates the measurement result automatically. In addition to the microprocessor and related circuits, the spectrophotometer has four main components: light source, integrating sphere, grating (monochromator), and photodetector. Different models of spectrophotometers have different components, which affect the accuracy of the measurement results.

Spectrophotometers, as precise measurement instruments, have a unique measurement method that is not complicated. It mainly consists of four steps:

1. Calibration

In actual use, calibration is required to ensure accuracy. There are two calibration methods: one is to use standard samples to calibrate, and the other is to use raw data from the light source for calibration. Calibration can ensure that the spectrophotometer has consistent standards under different test conditions.

2. Sampling

Before testing, a sample of the object needs to be taken. This step usually requires taking a small piece from the surface of the object while avoiding contamination and damage to the sample surface as much as possible.

3. Measurement

Before measuring, the sample needs to be fixed on the spectrophotometer according to the requirements. Then, using the instrument’s built-in operating interface, input the required measurement items and illuminate the sample with the light source. After a certain test time, the test data is recorded.

4. Analysis and Results

After obtaining the measurement data, it is necessary to perform analysis and statistics and further processing based on the analysis results. For example, by calculating the color difference value, the level of color difference from the standard sample can be determined, thereby determining the color accuracy.

As a highly precise color inspection device, spectrophotometers can detect the “reflectivity curve” of each color point, which cannot be achieved by many simple color difference meters. In addition, spectrophotometers can simulate multiple light sources, allowing you to perform color difference calibration work in the designated light source box specified by the inspection company.

Read the full article

0 notes

Text

How and why of masterbatches

Over the years, masterbatches’ production has gained momentum, riding on the increased demand for plastic-made items and rapid industrialization.Masterbatch manufacturers in India haven’t been left behind in terms of growth from their global counterparts.

In this blog, we are going to highlight masterbatch, why, and how it has become an integral part of the plastic industry.

Before we take deep dive into the subject, it makes sense to learn about the product.

What is a masterbatch?

Masterbatch is a solid additive engineered for plastic. It is designed for adding color to plastic-made items. At the same time, the product imparts a wide range of properties to plastics. Latter is called additive masterbatches. It is a concentrated mixture of pigments or additives. Which is encapsulated during a heat process into a carrier resin. This mixture is then cooled and cut into a granular shape.

For in-depth knowledge about the product, you can connect with a leading masterbatch manufacturer in India, Ahmedabad.

Unique features of masterbatch

Plenty of unique features make this product suitable for the plastic industry. Here are a few important qualities of masterbatches that make them ideal for various items made using plastic:

High jets

No Issues of bleed or bloom

Easy to process

UV stability

Uniform dispersion

Resistant to high-temperature

Types of masterbatches

According to a reputed masterbatch manufacturer, there are five major types of masterbatches. These are:

White Masterbatch

Black Masterbatch

Colour Masterbatch

Additive Masterbatch

Special Effect Masterbatch

Additive masterbatches

Additive masterbatches are designed to prevent deterioration that occurs due to heat and shear during processing. At the same time, protects the end product from the harmful impact of radiation and oxidation. Furthermore, the product by a reputed masterbatch supplier limits fire and resist reaction and further spread.

Packaging

Consumer goods

Automotive

Building & construction

Agriculture

Industries drawing benefits from masterbatches and additives

Over the years, masterbatch technology has evolved a lot, enabling masterbatch manufacturers in India to manufacture quality-driven products. Numerous industries are drawing benefits from the product. These include:

Agriculture

Lamination

Packaging

FMCG (Fast Moving Consumer Goods)

Custom-made masterbatches

Prominent masterbatch manufacturers in India hold the expertise to deliver custom-designed solutions. Their team of engineers and technicians has the rich professional experience to manufacture masterbatches and additive masterbatches according to the requirements of clients.

How to use technology to choose a Masterbatch supplier

If you are looking for a specific kind of masterbatch for your plastic-based industry, you can connect with an established masterbatch manufacturer. Never compromise the quality of the product. In this era of technology, finding a reputed manufacturer isn’t a big challenge. Go the Google, and enter a relevant keyword like masterbatch manufacturer in Ahmedabad. The search engine will come up with result pages with links. Click the first few links. Browse their website completely, before taking the final decision. You can also connect with their sales and customer support team. Always remember, unless the quality of the product matches your requirement, never buy it.

About Sumiran Masterbatch

We are a professionally managed company with more than 25 years of experience as a leading manufacturer and supplier of a wide range of masterbatches and additives, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others. Our product range is known for optimized performance and efficiency.

Are you searching for masterbatches for your plastic industry? End your search with Sumiran Masterbatch. Why go further?

9 notes

·

View notes

Text

Your Premier Calcium Carbonate Powder Manufacturer

In the world of industrial applications, Calcium Carbonate Powder Manufacturer holds immense significance. It's a versatile compound utilized across various sectors, from pharmaceuticals to plastics, and from paints to paper. Among the leading players in this domain, Sudarshan Group shines bright as a premier calcium carbonate powder manufacturer.

With a commitment to quality, innovation, and sustainability, Calcium carbonate powder, a vital ingredient in numerous industries, requires meticulous manufacturing processes to ensure its quality and purity. we understands this necessity and employs cutting-edge technology coupled with rigorous quality control measures to produce calcium carbonate powder that meets and exceeds industry standards. Through continuous research and development initiatives, we ensures that its products are tailored to meet the evolving needs of its diverse clientele.

The applications of calcium carbonate powder are as diverse as the industries it serves. In the pharmaceutical sector, it finds usage as an essential component in antacids and calcium supplements. Its high purity and fine particle size make it ideal for pharmaceutical formulations, ensuring efficacy and safety. In the plastics industry, calcium carbonate powder acts as a cost-effective filler, enhancing the mechanical properties of polymers while reducing production costs. Moreover, its presence in paints and coatings improves durability, opacity, and weather resistance, making it indispensable in architectural and automotive coatings.

The paper industry also relies heavily on calcium carbonate powder as a coating pigment and filler. we ensure the critical role played by calcium carbonate in improving paper quality, enhancing printability, and reducing production costs. By offering tailored solutions to meet specific requirements,we had established a preferred partner for leading paper manufacturers.

Sustainability is a core value at Sudarshan Group, and it reflects in every aspect of its operations. From responsibly sourced raw materials to eco-friendly manufacturing processes, we ensures minimal environmental impact. By prioritizing energy efficiency and waste reduction, we strives to contribute positively to the planet while meeting the growing demands of its customers.

In addition to its commitment to quality and sustainability, we places immense emphasis on customer satisfaction. With a dedicated team of experts and a customer-centric approach, we provides unparalleled support to its clients, ensuring seamless collaboration and mutual growth. By understanding the unique requirements of each customer and offering customized solutions, we fosters long-term partnerships built on trust and reliability.

In conclusion, we stands as a beacon of excellence in the realm of calcium carbonate powder manufacturing. With its unwavering commitment to quality, innovation, and sustainability, we continues to set new benchmarks in the industry. Whether it's catering to the pharmaceutical, plastics, paints, or paper sector, Sudarshan Group remains at the forefront, delivering superior products and services. Choose us as your trusted partner for all your calcium carbonate powder needs and experience the difference firsthand.

0 notes

Text

A Guide to Using and Handling Permanent Makeup Needles

As a permanent makeup (PMU) artist, you need to know your tools, how to use them, and how to handle them. Among these tools, PMU needles are especially crucial, as they influence everything from your work's precision to your client's comfort. Whether you're a novice or a seasoned PMU professional, understanding your needles can help ensure your work is high-quality and your clients are satisfied. This post will provide valuable information on using, handling, and caring for tattoo needles.

What are PMU needles?

PMU needles prick the skin and deliver pigment into the dermal layer, creating tattoos that naturally enhance the client's features or look like regular light makeup. These tattoos last for several years before needing a touchup, and they help clients look their absolute best while using little to no cosmetic products. PMU tattoo needles come in various configurations and sizes to suit different procedures.

What are the different types of PMU tattoo needles?

Understanding the tattoo needles for all PMU procedures is crucial for achieving your desired outcome. The most common types include:

Round liners (RL). This type of needle is perfect for fine lines and detailed work. 3RL tattoo needles are a popular choice for creating hair strokes in eyebrow procedures.

Flats and magnums (F and M). These needles allow for efficient application of pigments over broad surfaces, making them suited for shading and filling large areas.

Hybrid needles. These needles combine the characteristics of several configurations to achieve specific effects. For example, Grip Needles' TriFlat™, a 3RL and flat hybrid, increases the efficiency of stippling and similar techniques. It can be used to create realistic hair strokes, line the lips, and pixelate eyebrows.

Like regular tattoo needles, PMU needles come in different tapers and diameters. Which you select depends on several factors, including the client's skin type. For example, you may want to use needles with larger diameters on clients with thick and oil skin to optimize pigment retention.

How do you care for tattoo needles?

Caring for tattoo needles involves more than just disposing of them properly. Make sure all your needles are sterilized before each procedure to eliminate disease-causing pathogens. The use of disposable tattoo needle cartridges is standard for both PMU and body art. These are single-use, pre-sterilized needles encased in plastic housings. They reduce the risk of cross-contamination and are easy to swap out, so you can change configurations and sizes quickly during procedures.

When using tattoo needle cartridges, check the packaging to ensure they have not expired. Once they are past their expiry date, PMU needles are no longer safe to use and must be safely disposed of. When throwing away used or expired needles, make sure to place them in a proper sharps container so they can be picked up by or mailed to a service specializing in medical waste disposal.

Finally, you should source your needle cartridges from reputable manufacturers to ensure they are made from high-quality materials and are engineered for durability and optimal performance. This prevents issues like needle breakage, which can lead to unsatisfactory results and potential harm to clients.

PMU needles are a fundamental aspect of permanent makeup and a vital component of your toolkit as a PMU professional. You need to understand how to use them and choose the appropriate needle for specific procedures. It's also crucial that you know the methods of handling tattoo needles and caring for them. This way, you ensure that you can reliably and safely produce results that will satisfy your clients.

0 notes

Text

Innovating Colors: The Rise of Color Masterbatch Manufacturers in India

Introduction:

In the vibrant world of plastics, color plays a crucial role in aesthetics, branding, and product differentiation. As the demand for colorful and visually appealing plastic products continues to rise, the importance of color masterbatches cannot be overstated. In India, a burgeoning hub for plastics manufacturing, color masterbatch manufacturers are emerging as key players, driving innovation and meeting the diverse needs of various industries. Let's explore the landscape of color masterbatch manufacturing in India and uncover the unique contributions of these manufacturers.

Quality and Consistency:

One of the primary factors contributing to the success of color masterbatch manufacturers in India is their commitment to quality and consistency. These manufacturers adhere to stringent quality control standards throughout the production process, ensuring that each batch of color masterbatch meets the desired specifications. By utilizing state-of-the-art equipment and advanced manufacturing techniques, they achieve uniform dispersion of pigments or dyes within the polymer matrix, resulting in vibrant and consistent colors in the final plastic products. This dedication to quality has earned Indian color masterbatch manufacturers a reputation for reliability and excellence in both domestic and international markets.

Customization Capabilities:

In addition to producing high-quality color masterbatches, manufacturers in India offer extensive customization capabilities to cater to the unique requirements of their clients. Whether it's matching specific Pantone shades, creating custom color formulations, or incorporating special effects like metallic finishes or pearlescent hues, Indian color masterbatch manufacturers possess the technical expertise and flexibility to fulfill diverse customer demands. This ability to tailor color solutions according to individual preferences enables brands to stand out in crowded markets, enhance brand recognition, and create compelling visual experiences for consumers.

Technological Advancements:

The rapid advancements in technology have significantly transformed the landscape of color masterbatch manufacturing in India. Leading manufacturers invest in research and development to stay abreast of the latest trends, materials, and processing technologies. From innovative pigment dispersion techniques to the use of nano-additives for enhanced color stability and performance, Indian color masterbatch manufacturers leverage cutting-edge solutions to push the boundaries of color possibilities. This continuous pursuit of innovation not only drives product differentiation but also enables manufacturers to offer value-added solutions that address evolving market demands.

Sustainability Initiatives:

With growing awareness about environmental sustainability, color masterbatch manufacturers in India are increasingly focusing on eco-friendly solutions. Many companies are adopting sustainable practices such as utilizing bio-based and recycled materials, reducing energy consumption, and minimizing waste generation throughout the manufacturing process. By prioritizing sustainability, these manufacturers not only contribute to environmental conservation but also align with the preferences of eco-conscious consumers and brands. Additionally, the development of bio-degradable and compostable color masterbatches further underscores India's commitment to sustainable innovation in the plastics industry.

Collaborative Partnerships:

Indian color masterbatch manufacturers actively foster collaborative partnerships with clients, resin suppliers, and end-users to drive mutual growth and innovation. By engaging in open dialogue and understanding the specific needs of each stakeholder, manufacturers can co-create tailored color solutions that deliver maximum value. Whether it's providing technical support, conducting color-matching trials, or offering product customization services, these collaborative efforts strengthen relationships and foster long-term partnerships based on trust, reliability, and shared success.

Conclusion:

In conclusion, the rise of color masterbatch manufacturers in India underscores the country's growing prominence as a hub for plastics innovation. With a focus on quality, customization, technological advancement, sustainability, and collaborative partnerships, Indian manufacturers are poised to play a significant role in shaping the future of color solutions for the global plastics industry. As consumer preferences evolve and market dynamics continue to change, Indian color masterbatch manufacturers stand ready to meet the challenges and seize the opportunities that lie ahead, driving innovation and adding vibrancy to the world of plastics.

0 notes

Text

Precision and Consistency in Multi-Color Injection Molding Comprehensive of Techniques and Strategies

In the dynamic realm of manufacturing, achieving precise and consistent colors in multi-color injection molding is pivotal for producing high-quality products. This article delves into the intricate world of multi-color injection molding, examining the techniques and strategies employed to ensure the accuracy and uniformity of colors throughout the production process.

Multi-color injection molding has emerged as a revolutionary process, enabling manufacturers to create visually stunning and intricate designs. However, the challenge lies in maintaining the precision and consistency of colors, a critical aspect of meeting stringent quality standards. This article aims to dissect the methodologies employed in multi-color injection molding to guarantee the exactitude and uniformity of colors in the final products.

Before delving into ensuring color accuracy, it is imperative to comprehend the fundamentals of multi-color injection molding. The process involves injecting multiple colors of molten plastic into a mold to produce a single, integrated product. This complexity requires meticulous attention to detail in each step of the manufacturing journey.

Several factors influence the color accuracy in multi-color injection molding, ranging from material selection to machine settings. The type of plastic used, pigment concentration, and the compatibility of different colors play pivotal roles in determining the outcome. Additionally, temperature, pressure, and cycle time must be precisely controlled to achieve consistent results.

Achieving the desired color in multi-color injection molding demands advanced color-matching techniques. Spectrophotometers and colorimeters are employed to analyze and match colors with high precision. These instruments ensure that the colors injected into the mold align with the specified requirements, discrepancies, and variations.

The selection of suitable materials is a cornerstone in ensuring color accuracy. Manufacturers must carefully choose pigments and dyes compatible with the base resin to prevent color bleeding or fading during the injection process. Compatibility testing is a crucial step in guaranteeing the long-lasting vibrancy of colors in the final product.

Fine-tuning machine parameters is a critical aspect of multi-color injection molding. Manufacturers must meticulously adjust injection pressure, temperature profiles, and cooling times to achieve consistent color distribution. Modern injection molding machines equipped with precision control systems facilitate the optimization of these parameters, ensuring enhanced color accuracy.

To maintain color consistency, real-time monitoring, and quality control measures are indispensable. Automated systems equipped with sensors continuously monitor color variations during the injection process. Any deviations from the predetermined color specifications trigger immediate adjustments, preserving the integrity of the final product.

Efficient color changeovers are paramount in multi-color injection molding, especially in scenarios requiring frequent color transitions. Quick and effective purging procedures, automated cleaning systems, and optimized tooling designs contribute to reducing downtime between color changes, enhancing overall production efficiency.

The relentless pursuit of perfection in multi-color injection molding has led to continuous innovations in color control technologies. Smart injection molding systems utilize artificial intelligence and machine learning algorithms to predict and adjust color variations in real-time. These adaptive technologies contribute to the evolution of color accuracy in the manufacturing landscape.

Despite technological advancements, challenges persist in achieving absolute color accuracy. Issues such as color bleeding, inconsistent pigment dispersion, and tooling limitations may arise. This section explores these challenges in detail, offering viable solutions and preventive measures to mitigate their impact on the final product.

In the pursuit of color accuracy, manufacturers are increasingly mindful of environmental concerns. This section explores eco-friendly practices and sustainable material choices within the multi-color injection molding process, aligning with the global push towards greener manufacturing.

Highlighting successful implementations of multi-color injection molding, this section presents case studies across diverse industries. Examining real-world scenarios showcases how manufacturers have overcome challenges to achieve color precision and consistency in their products.

0 notes

Text

Bottom Discharge Centrifuge Manufacturer

Falgun Engineering Enterprise Manufactures Bottom Discharge Centrifuges in Ahmedabad, Gujarat, India.

Our company is ISO 9001:2015 certified, based in Ahmedabad, Gujarat, India.

Falgun Engineering Enterprise is renowned for producing a diverse range of centrifuge machines.

We are a leading provider of Pusher Centrifuges to various Multi-Effect Evaporator manufacturers as OEMs.

Specializing in Hydraulic and Mechanical Pusher Centrifuges for industries such as salt, chemical, and MEE/MVR, along with Bottom Discharge Centrifuges, Bag Shifting Centrifuges, and Decanter Centrifuges.

Our machines offer optimal solutions, especially in scenarios requiring continuous operation and automation, ideal for multiple effect evaporator systems.

Constructed with high-grade iron metal and carbon alloy, our machines are coated with heat-resistant paint, ensuring durability against high temperatures and water exposure.

Features:

Design for High Separation Efficiency

Simple removal of separated solids from the bottom ensures convenient and uninterrupted operation.

Produces exceptional product quality by exact separation, meeting the highest industry standards.

Reduces downtime with effective discharge systems, enabling continuous processing.

Application:

Chemical Industry

Pharmaceuticals

Food and Beverage Processing

Mining and Minerals

Environmental and Effluent Treatment

Biotechnology and Pharmaceuticals

Chemical Catalyst Recovery

Dyes and Pigments Production

Petrochemical Industry

Oil and Gas Processing

Plastics Industry

Textile Industry

Falgun Engineering Enterprise is a Bottom Discharge Centrifuge Manufacturer in Ahmedabad, Gujarat, India and Supplier of Bottom Discharge Centrifuge in Gujarat and including location like Ahmedabad, Amreli, Bharuch, Bhavnagar, Bhuj, Dwarka, Gandhinagar, Godhra, Jamnagar, Junagadh, Kandla, Khambhat, Kheda, Mahesana, Morbi, Nadiad, Navsari, Okha, Palanpur, Patan, Porbandar, Rajkot, Surat, Surendranagar, Valsad, Veraval, and more.

For more information and inquiries, feel free to contact us.

0 notes