#Compressed Air Treatment Equipment Market Size

Text

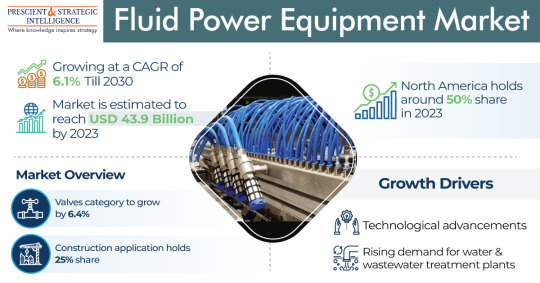

Fluid Power Equipment Market Will Touch USD 66.0 Billion in 2030

The fluid power equipment market was USD 43.9 billion in 2023, which will rise to USD 66.0 billion, advancing at a 6.1% compound annual growth rate, by 2030.

The growth of this industry is mainly because of the increasing need for water and wastewater treatment plants, and the continuous technological developments.

In 2023, hydraulic led the type category, with a revenue of USD 26.3 billion. This can be ascribed to the cost-effectiveness and high efficiency of this type, and its extensive adoption in oil & gas and construction applications.

The pneumatic category, on the other hand, will propel at a healthy rate during this decade. This is because these systems rely on compressed air pressure to send power and are extensively employed in numerous industrial applications.

Furthermore, pneumatic valves are available in different designs, sizes, and configurations, and thus, allow free flow in a single direction and avoid flow in the opposite direction.

In 2023, the construction category, based on end user, was the largest contributor to the fluid power equipment market, with a 25% share. This can be because of the high usefulness of these components in various applications like material demolition or handling in the construction sector.

The automotive category, on the other hand, is advancing at a tremendous rate, because of the increasing customer's disposable salary, along with the increasing standards of living, worldwide.

Motors is leading the component category. This can be because motor components provide great torque & power, and are extensively employed across various sectors, including agriculture, construction, and automotive.

Moreover, the developments in motor technologies enhance their performance and efficiency, and thus, are cost-effective solutions for businesses to utilize for different applications.

On the other hand, the valves category will advance at the highest rate during this decade. This is ascribed to the growing requirement for valves to track high pressure, which will boost the demand for valve components.

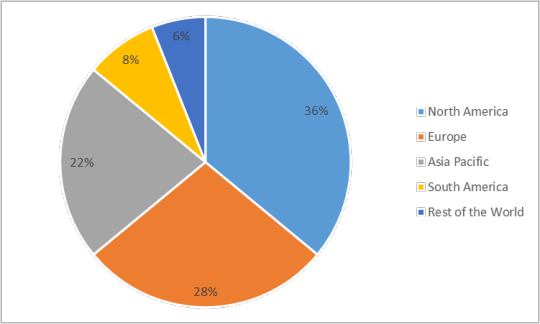

North America led the industry in 2023, with a 50% share. This can be attributed to the existence of greater infrastructure, coupled with the rising progression in R&D and manufacturing activities.

Moreover, the increasing count of initiatives implemented to guarantee the worker's safety in oil & gas and chemicals sectors further boost the regional industry growth.

APAC will propel at the highest rate, of 6.5%, in the coming years. This will be because of the surging urbanized populace along with the increasing requirement for energy, and the progression of the construction and automobile sectors in Japan, China, and India.

With the rise in the requirement for water & wastewater treatment plants, the fluid power equipment industry will continuously progress in the coming years.

Source: P&S Intelligence

#Fluid Power Equipment Market Share#Fluid Power Equipment Market Size#Fluid Power Equipment Market Growth#Fluid Power Equipment Market Applications#Fluid Power Equipment Market Trends

1 note

·

View note

Text

0 notes

Link

0 notes

Text

Harm of Using Inferior Filter Elements in Diesel Generator Sets

Do you know the hazards of using inferior filter elements when maintaining diesel generator sets? Below, diesel generator manufacturers will provide a detailed summary for everyone. Due to the uneven quality of filter manufacturers, filters were originally designed to filter harmful impurities from various substances entering diesel generator sets. Enable the diesel engine to operate normally under various operating conditions and achieve the specified service life. However, counterfeiting, especially inferior filters, not only fails to achieve the aforementioned effects, but also brings various hazards to the engine.

There are several common hazards. Firstly, use inexpensive filter paper to make filter elements. Due to the large pore size, poor uniformity, and low filtration efficiency of the filter paper, harmful impurities entering the engine cannot be effectively filtered, resulting in early engine wear. If low-quality adhesive is used, it cannot be firmly adhered, causing a short circuit at the bonding point of the filter element; Allowing a large amount of harmful impurities to enter the engine will reduce the lifespan of diesel engines.

Replacing oil resistant rubber parts with ordinary rubber parts, during use, due to the sealing failure of the internal sealing parts, a short circuit is formed inside the filter, causing some oil or air containing impurities to directly enter the engine, causing early engine wear. And the material of the center tube of the engine oil filter is thin instead of thick, which is not strong enough. During use, due to the center tube being compressed and the filter element being damaged, the oil circuit is blocked, resulting in insufficient engine lubrication. Metal components such as the end cover of the filter element, central tube, and casing are not subjected to rust prevention treatment, resulting in metal rust and impurities, making the filter a source of pollution.

Jiangsu Dingbo Power Generation Equipment Co., Ltd. has been established for many years. In addition to strict requirements on the quality of diesel generator set products and after-sales service, it also has strict regulations on the plant environment, production equipment and supporting facilities, which reflects the strict style of Dingbo people. It is not only responsible for generator products, customers, but also employees, so that every employee of Dingbo Power generation equipment can work in a comfortable environment, Make it comfortable for every visiting customer to visit. Dingbo Power Group, relying on high-quality generators, generator sets, diesel generator, diesel generator sets, good services and the care of friends from all walks of life, carries forward the enterprise spirit of "pragmatic innovation, pioneering, unity and hard work, dare to be the first", and adheres to the enterprise style of "treating people with sincerity and heart to heart", has won the strong support of customers in the fields of post and telecommunications, finance, petrochemical, metallurgy, transportation, education, medical care, etc, Having a proud performance. Dingbo people are gradually moving towards economies of scale and entering the international market after joining the WTO with flexible sales strategies and relying on the company's advantages and strength. If you would like to get more information welcome to contact us via [email protected].

0 notes

Text

Shale Gas Processing Equipment set for Significant Growth

The global shale gas processing equipment market size was valued at $4.5 billion in 2018, and is projected to reach $13.5 billion by 2026, growing at a CAGR of 14.8% from 2019 to 2026.

The major key players operating in the global shale gas processing equipment industry include Schlumberger Ltd, Sivalls, Inc, Van Air Systems, Croft Production Systems, Inc., Koch Industries, Inc., Pall Corporation, PEMCO, Burckhardt Compression AG, Gas Processing Equipment, and ATB Riva Calzoni S.p.A.

Get a PDF brochure for Industrial Insights and Business Intelligence:

Shale gas equipment are used to eliminate components such as N2, H2S, heavy hydrocarbons, CO2, and water from the raw shale gas and oil before it is sent for transportation. This method includes various processes such as distillation, filtration, cracking, reheating, pyrolysis, and chemical treatment.

As per the U.S. energy information administration, the global shale gas industry surpassed more than $200 billion revenue in 2018 and as per their estimates it is anticipated to generate more than $390 billion revenue by 2025. Shale gas and oil infrastructure and markets for their related products, more specifically, processing equipment, altogether are heading toward their growth expansion phase as whole.

Due to abundant shale gas reserves, its infrastructure expected to grow significantly over the next decade. Hence, processing equipment is expected to have a promising future over the years to come

The U.S. reported shale gas production of over 37 billion cubic feet following Mexico and China at over 5 and 2.1 billion cubic feet respectively in 2015. As per the estimates of U.S. Energy Information Administration, the U.S. anticipated to produce over 80 billion cubic feet of shale gas by offering a scope to huge technological investment along with processing equipment manufacturing.

Equipment used in the shale gas processing are known as shale gas processing equipment. Popularly known equipment used in the shale gas processing include compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Apart from these, the others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. These equipment are used in the midstream phase of the oil & gas industry, wherein, gas/shale gas is processed, refined, and treated before it is transported for commercial usage.

Abundance shale gas reserves in some of the geographies across the globe and its commercial exploitation is the major factor and it has an immense impact on the global market growth. In response to the increasing natural gas prices, oil & gas industry seeks an alternative

to natural gas resources at economic terms. Shale gas is nothing but a natural gas trapped within a shale formation whose reserves are spread almost all across the globe.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/1007

Heat exchanger is important equipment used in the overall gas processing plants. Technological evolution of heat exchangers is further contributing in the global shale gas processing equipment market growth. On the other hand, environmental hazards associated with hydraulic fracturing is the major restraining factor hampering the growth of the global shale gas processing equipment market. Nevertheless, growing initiatives from government from various geographies is anticipated to offer new growth opportunities over the forecast period.

The global shale gas processing equipment market is segmented on the basis of component and country. On the basis of component, the global market is studied across compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. Compressor and pumps is the largest segment among all and its growing demand is significantly expanding the global shale gas processing equipment market size.

Based on country, the global shale gas processing equipment market is studied across the U.S., Canada, China, Algeria, Mexico, Argentina, and others. The U.S. is the largest country level market among others due to abundant shale gas reserves and technically sound nature of the country, and investment in the shale gas exploration. Increased penetration of small-scale and mid-scale processing equipment manufacturers over large scale equipment manufacturers in the U.S. is one of the recent shale gas processing equipment market trend observed in recent years.

Browse complete industry report : https://www.alliedmarketresearch.com/shale-gas-processing-equipment-market

The U.S. is the largest country level market among others. The U.S. is the first country that has undertaken successful commercial scale production of shale gas and is offering scope to gas processing equipment. Therefore, the U.S. has the dominant share in the global shale gas market and is expected to be the largest one during the forecast period.

Based on component, Compressors and pumps segment accounted for the largest market share in 2018 and is expected to be the largest segment by the end of the forecast period. Demand for compressors is mainly seen in the U.S. as it is the largest market for shale gas processing equipment. Gas processing capacity have expanded in most of plants located in the U.S. as a result of increasing shale gas production. Hence, demand for compressors is rising in the U.S.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

5933 NE Win Sivers Drive

205, Portland, OR 97220

United States

USA/Canada (Toll Free):

+1-800-792-5285, +1-503-894-6022

UK: +44-845-528-1300

Hong Kong 852 - 301 - 84916

India (Pune): +91-20-66346060

Fax: +1(855)550-5975

Web: www.alliedmarketresearch.com

Allied Market Research Blog:

Follow Us on Facebook | LinkedIn | YouTube

0 notes

Text

How Pressure Reducers Can Improve the Efficiency and Safety of Your Industrial Systems.

Pressure is a crucial factor in ensuring that your equipment operates efficiently and safely. That's where pressure reducers come in. We will also provide tips on choosing the right pressure reducer for your system, installation, and maintenance. Finally, we will introduce you to our company, Resilient Gate Valve, and explain why we are the best choice for your pressure reducer needs.

Understanding the Basics of Pressure Reducers and Their Importance in Industrial Systems

The main purpose of a pressure reducer is to maintain a consistent pressure level in the downstream system, regardless of changes in the upstream pressure.

Different Types of Pressure Reducers Available in the Market

Direct-acting pressure reducers are simple and economical, but they are not suitable for high-pressure applications. Pilot-operated pressure reducers are more complex and can handle higher pressure levels. Dome-loaded pressure reducers are used in critical applications where high accuracy and reliability are required.

Factors to Consider When Choosing the Right Pressure Reducer for Your System

You also need to consider the materials used in the pressure reducer, as they can affect its performance and lifespan.

Installation and Maintenance Tips for Pressure Reducers

Proper installation and maintenance are essential for the optimal performance and longevity of your pressure reducer. When installing a pressure reducer, make sure it is installed in the correct orientation, with the inlet and outlet connections properly aligned. Regular maintenance, including cleaning and inspection, can help prevent issues such as leaks and corrosion.

Benefits of Using Pressure Reducers in Industrial Systems

Using pressure reducers in industrial systems can provide several benefits, including improved efficiency, reduced energy consumption, and increased safety. By maintaining a consistent pressure level, pressure reducers can also extend the lifespan of your equipment and reduce maintenance costs.

Applications of Pressure Reducers in Various Industries

In chemical processing, pressure reducers are used to regulate the pressure of gases used in chemical reactions. In water treatment, pressure reducers are used to regulate the pressure of water distribution systems. In manufacturing, pressure reducers are used to regulate the pressure of compressed air systems and other industrial gases.

Common Issues That Can Affect the Performance of Pressure Reducers

Like any mechanical device, pressure reducers can experience issues that affect their performance. Some common issues include leaks, corrosion, and blockages. Poor installation, incorrect sizing, and inadequate maintenance can also cause issues with pressure reducers. It is essential to address any issues promptly to prevent damage to your equipment and ensure the safety of your workers.

Why Resilient Gate Valve is the Best Choice for Your Pressure Reducer Needs

Resilient Gate Valve is a leading provider of high-quality pressure reducers and other industrial valves. Our pressure reducers are made from durable materials and designed to provide reliable performance in even the most demanding environments.

Conclusion : pressure reducers are essential devices for maintaining optimal pressure levels in industrial systems. Proper installation and maintenance are also essential for the optimal performance and longevity of your pressure reducer. At Resilient Gate Valve, we offer a wide range of high-quality pressure reducers and exceptional service and support to ensure the success of your industrial system.

0 notes

Text

Different types of agriculture sprayers and their uses

A sprayer is a machine often used in agricultural contexts to spray various liquids, including water, insecticides, and pesticides, among other things. The same machinery might also be used to apply liquid fertilizers and pesticides to the crops grown on your farms. Spray guns, spray nozzles, liquid tanks, sprayer pumps, pressure regulators, valves, and fluid pipework are the standard components that make up agricultural sprayers. A pressure regulator is an extra feature that may be included on some sprayers. Farmers can spray high up on trees such as mango, coconut, and date palms using a tractor trailed sprayer.

Today’s market offers a wide selection of different models and styles of sprayers to choose from. Farmers can obtain a larger harvest with the assistance of the newly released Mitra Agro Low Volume sprayer. These sprayers are versatile enough to serve several applications, including gardening, crop spraying, and other requirements unique to gardening. In a perfect world, the sprayers come in various sizes, designs, and operational parameters.

Some agricultural sprayers also have a spray gun in addition to the standard spray nozzle, liquid tank, sprayer pump, pressure regulator, valves, and fluid piping. These agricultural sprayers are available in various sizes, styles, and performance levels. There is a wide range of sprayers available, from those designed to cover a small amount of land to those intended to cover a vast area.

For spraying purposes as varied as gardening, crops, trees, fruits, animal requirements, and weed control, a wide variety of sprayers are available. There is a fair probability that you are aware of using agricultural sprayers whether you are a farmer or if your job involves working on a farm. They are available in a wide range of forms and dimensions, and each is put to a specific purpose.

On any given farm, they serve several purposes, whether giant versions designed to be attached to tractors or smaller ones that can be carried about independently. Even if you do not intend to cultivate crops on your land, sprayers may greatly assist your property’s management and the upkeep of its quality.

The following sprayers are only some of the wide available varieties:

· Since the method includes spraying water or liquid chemicals to a restricted land area, a hand-operated sprayer is an ideal choice if you are looking for modest plant treatments. This is your best option. Sprayers that do not need air are the most effective option for treating large areas of plants. Using an air pump, the sprayer achieves its effects; first, it pumps compressed air into the tanks and pressurizes the liquid.

· Once the pressure inside the sprayer decreases, the spray pattern will move more slowly. This will continue until the pressure is back up. Before the spraying process can commence, the applicator has to have the air pumped out of it first. Even though it only runs at low pressures, the fact that this sprayer is not only affordable but also portable and straightforward to use makes it the most attractive feature of the product.

· Sprayers that have a significant amount of pressure The size and number of tanks required will determine whether you should acquire a tractor mounted sprayer, a trailer-mounted sprayer, or a truck-mounted sprayer. Each type of sprayer has both advantages and disadvantages. In this case, hydraulics serves as the primary force that is responsible for how they operate. They come equipped with a pressure indicator, control valves, and a hermetically-sealed air chamber.

· Air carrier/air-assisted sprayer: With the assistance of air carriers and air-assisted sprayers, it is possible to apply dangerous chemicals in vast amounts in a manner that is both rapid and effective. While being transported, the chemicals have their concentrations reduced. A sprayer that is designed specifically for use on fruit trees is known as an orchard sprayer.

· Foggers can transform liquid pesticides into a vapor that can be sprayed using the device. These sprayers are the most useful when dealing with an infestation of a crop pest or in a controlled setting like a greenhouse. The usage of an orchard sprayer is essential to spray horticulture crops effectively.

Mitra has expanded to become India’s most prominent manufacturer of agricultural spraying equipment. Some of the products that Mitra produces include tractor-mounted sprayers and an air blast sprayer, as well as dusters, boom, micro tractor sprayers, and orchards and vineyards. Because of this, there are a lot of sprayers, and you may use any of them according to your needs.

If you’re looking for high-quality agricultural goods, go no further than Mitra Agro. We’re a manufacturer and supplier of cutting-edge farming equipment for micro and small farms. If you have any questions or concerns about our products, please leave a message, and a customer service person will contact you as soon as possible.

0 notes

Text

How Technology is Affecting the Compressed Air Treatment Equipment Market: Implications for Businesses 2023

Compressed Air Treatment Equipment Market Global Industry Research Report provides market size, share, industry growth, development trends, business ideas, and forecasts by 2031. Scenarios and useful business decisions.This report provides a detailed analysis of subjective, comprehensive research as well as quantitative perspectives from key manufacturers. It also includes in-depth information…

View On WordPress

0 notes

Text

https://community.wongcw.com/blogs/298500/Compressed-Air-Treatment-Equipment-Market-Trends-Emerging-Technologies-Size-and

Compressed Air Treatment Equipment Market Size, Share, Competitive Analysis, Research Methodology, Rapid Growth and Fast Forward Research till 2030

0 notes

Text

https://twikkers.nl/blogs/94326/Compressed-Air-Treatment-Equipment-Market-size-Share-Growth-Latest-Trends

0 notes

Text

Pressure Relief Devices Market is at the forefront to combat the ballooning cases of pressure ulcers with the advent of advanced equipment

The pressure relief devices help to prevent blood clots from forming and, eventually, clogging of the arteries. When a blood clot forms, it prevents oxygen from reaching the heart, and this causes it to stop functioning properly. This is usually bad news since most strokes and cardiac arrests can be prevented if the heart is able to work properly.

There are four different pressure relief devices classifications. Learn about what each one consists of and its function. Rupture Disk Devices: this device is basically a flat disk, which is usually made of plastic and designed in such a way to break at a certain pressure in order for the release of pent-up gas to allow the escape of gas through the valve. These devices are often used to relieve pressure on the skull. Decongestive pressure relief devices are devices which are used to decrease the amount of pressure that is put on the heart. They are often used along with rupture disks in order to increase their effectiveness.

Cylinder banks are pressure relief devices that sit directly under the sternum bone and pelvic bone. These devices are created out of an aluminum alloy, and the inner ring, which sits inside the cylinder, has an opening in it. A small pump is used inside the cylinder to push a controlled stream of air into the opening. This type of valve is often used in cardiac arrest, asthma, and other conditions where relief is needed immediately.

Compressed gas discs are pressure relief devices that consist of either one or two cylinders. The inside of the cylinder is filled with either air or a liquid, such as argon, oxygen, or nitrogen. Depending on the size of the tank, the volume of gas can vary significantly, depending on the patient's needs. This is due to the volume of the tank, which determines how fast the gas is able to escape. For example, the small-sized compressed gas cylinders available for long-term use are usually around 40 cc.

The pressure relief devices market is projected to be driven by the growing elderly population combined with the frequent occurrence of pressure ulcer formation owing to its highly sensitive nature. In addition, technological advances such as dynamic air therapy mattress, a rise in the overweight populace, and heightened recognition of pressure ulcers through initiatives in different nations are the key drivers broadening the scope for the pressure relief devices market. Conversely, the high cost of equipment and a scarcity of trained employees can cause a hindrance in the growth of the pressure relief devices market.

Across the geographical horizons, the North American is posing positive prospects for the pressure relief devices market on the heels of mounting chronic diseases among senescent patients compounded with the rising healthcare expenditures. Another noteworthy geographic region is Asia Pacific which is offering tremendous scope for the pressure relief devices market in the line of growing geriatric population and disposable incomes.

In March 2021, Tivic Health Systems confirmed to have received clearance from the U.S. FDA (Food and Drug Administration) for its ClearUp Sinus Pain Relief in the treatment of allergies. In August 2021, the investment company, Bansk Group, acquired Arcadia Consumer Healthcare from Avista Capital Partners to venture in the healthcare market.

0 notes

Text

The development of Compressor nebulizer:

With the intensification of air pollution such as smog and the weakened immunity of children and the elderly, more and more people are suffering from respiratory diseases such as asthma and pneumonia. With the widespread use of medical nebulizers, due to its many advantages over traditional drug treatment, people gradually recognize and accept nebulizer inhalation therapy, and try to nebulize from queuing in hospitals to purchasing household nebulizers by themselves. A nebulizer for high-quality treatments that can be easily nebulized at home. Whether it is a medical nebulizer or a household nebulizer that is gradually becoming popular, there are many brands on the market, which are a bit dazzling. So which atomizer brand is more professional, reliable and cost-effective, and how to choose a good home atomizer, many people do not understand. What are the requirements for a good home atomizer?

Advantages of Compressor nebulizers:

Between compressor nebulizers and ultrasonic nebulizers, I personally think compressor nebulizers have a longer lifespan, are easier to maintain, and are relatively simple to operate than ultrasonic nebulizers. In fact, experts also gave some suggestions for purchasing atomizer brands. From the user's point of view: simple operation and portability are also important indicators for measuring Compressor nebulizer, while Omron compressed Compressor nebulizer are designed with one-button operation, which is easy to use even for children. And its small size makes it perfect for going out. The CNB69012 compression nebulizer is also specially equipped with a charger and rechargeable battery, as well as a carrying case. Take it with you when you go out to play or travel, and realize inhalation therapy anytime, anywhere. It is the only brand product of household atomizer. You can choose with confidence.

1 note

·

View note

Link

0 notes

Text

Medical & Pharmaceutical Gases & Equipment Market - Forecast, 2022-2027

Medical & Pharmaceutical Gases & Equipment Market size is estimated to reach $25.4 billion by 2027, growing at a CAGR of 6.2% during the forecast period 2022-2027. Medical and pharmaceutical gases can be delineated as fluids or specialized gases that are taken into account for performing several medical procedures, research, and manufacturing activities in the biopharmaceutical industry. Furthermore, gases equipment is the hardware or assemblies used to storm the gases and supply them when needed. Equipment such as cylinders, valve with integrated pressure regulators, vacuum insulated evaporators, and flow meters are considered in handling the storage and delivery of gases. Besides, storing and maintaining a constant supply few devices such as anaesthetic gas scavenging systems work as scavengers by removing the mixture of gases out of storage facilities and operating rooms in order to keep medical staff exempt from their exposure. Generally, oxygen, helium, argon, nitrogen, and compressed air are used as medical gases when performing therapeutic treatments and anesthetic procedures. Furthermore, gas equipment is the hardware or assemblies used to store the gases and supply them when needed. The medical & pharmaceutical gases & equipment market outlook is exceptionally enchanting ascribing to their colossal demand. Augmenting chronic ailments such as cardiovascular hitches, road tragedies, and mounting research and development spending are factors set to drive the growth of the Medical & Pharmaceutical Gases & Equipment Market for the period 2022-2027.

Report Coverage

The ort: “Medical & Pharmaceutical Gases & Equipment Market Forecast (2022-2027)”, by Industry ARC, covers an in-depth analysis of the following segments of the Medical & Pharmaceutical Gases & Equipment Market.

By Composition: Concentrate/Pure gases (Nitrogen, Helium, Carbon dioxide, Oxygen, and others), Dilute/Mixture gases (Blood gas mixtures, Sterilant gas mixtures, lung diffusion mixtures, and others).

By Application: Therapeutics, Anesthetic, and Research.

By Equipment Type: Masks, Manifolds, Air compressors, Cylinders, Hose assemblies, Flowmeters, and Others.

By End User: Hospitals, Clinics, Cancer treatment centers, ASCs, Biotech Industries, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Australia & New Zealand, and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America) and Rest of World (the Middle East and Africa).

Key Takeaways

Geographically, the North America Medical & Pharmaceutical Gases & Equipment Market accounted for the highest revenue share in 2021. However, Asia-pacific is poised to dominate the market over the period 2022-2027.

Enlarging the elderly population, a frantic upsurge in the prevalence of cardiovascular complications CVDs is said to be a preeminent driver driving the growth of the Medical & Pharmaceutical Gases & Equipment Market. whereas, health problems associated with medical gases are said to reduce the market growth.

Detailed analysis of the Strength, Weaknesses, and Opportunities of the prominent players operating in the market will be provided in the Medical & Pharmaceutical Gases & Equipment Market report.

Medical & Pharmaceutical Gases & Equipment Market Share, By Geography (%) in 2021

For More Details on This Report - Request for Sample

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By Composition

The Medical & Pharmaceutical Gases & Equipment Market based on the composition type can be further segmented into concentrate/Pure gases (Nitrogen, Helium, Carbon dioxide, Oxygen, and others), dilute/mixture gases (Blood gas mixtures, Sterilant gas mixtures, lung diffusion mixtures, and others). The concentrate gases segment held the largest share in 2021. The growth is owing to humongous demand as chronic obstructive pulmonary diseases are coming to the foreground like never before. COPD maladies like emphysema and chronic bronchitis are so severe that they inflict irreparable damage to the lungs which can’t be cured. Therefore, patients suffering from such conditions required constant medical care and treatment. On another hand, cases associated with cardiac arrest and trauma have heightened the use of medical oxygen. It can’t be proclaimed that only the pure gases segment will witness growth aspects over the undermentioned time frame because both of these gases’ usage go hand-in-hand. Mixture gases play a significant role in the maintenance of devices that distributes anesthetic gases. Moreover, they are also taken into consideration during lung diagnosis. Therefore, the concentrated along with dilute segment is estimated to be the fastest-growing segment with a CAGR of 7.8% over the forecast period 2022-2027.

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By End User

The Medical & Pharmaceutical Gases & Equipment Market based on end-user can be further segmented into hospitals, clinics, cancer treatment centers, ASCs, biotech Industries, and others. The hospital segment held the largest share in 2021. The growth is owing to broadening hospitalization trends as chronic illnesses are on the loose and roaming around the globe. Moreover, the COVID-19 has played a significant role in upsurging hospitalization. Many COVID patients witness lower levels of oxygen in the blood which drives the tissues and organs of the body to starve. This condition obligates constant access to oxygen. Therefore, to meet the shooting up demand hospitals are supposed to be in a fit state all the time to meet the requirements. In today’s world hospitals have a far-reaching presence throughout the countries whether it’s a city or pastoral area it doesn’t matter. That is why they have become the first and foremost point of contact for people who want to undergo some sort of treatment. Moreover, the hospital segment is estimated to be the fastest-growing segment with a CAGR of 7.3% over the forecast period 2022-2027. This growth is owing to the enlightening infrastructure of hospitals with heightened government spending post-COVID-19.

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By Geography

The Medical & Pharmaceutical Gases & Equipment Market based on Geography can be further segmented into North America, Europe, Asia-Pacific, South America, and the Rest of the World. North America held the largest share with 36% of the overall market in 2021. The growth in this segment is owing to the factors such as the heavy pervasiveness of asthma. The US dominates when it comes to bronchial asthma due to widespread obesity. According to the American Lung Association, being overweight can narrow the lungs by encircling pressure and set breathing difficulties in motion. More than 40% of adults in the US are obese. Similarly, gun violence leads to thousands of injuries every year, and the immense spread of cancer cases especially breast and lung cancer are quite high which is also driving the growth in the respective segment. However, Asia-pacific is expected to be the fastest-growing segment over the forecast period 2022-2027. This growth is owing to the soaring elderly population which is shooting up the incidences of heart attack and cancer. Besides cancer and heart attack the worst air quality is another big factor behind amplified hospitalization. India and China are home top cities with the worst particulate matter (PM2.5) concentration which impairs the lungs of residents more than 30 times the WHO satisfactory levels. According to a report published in 2021, Asia is the epicenter of the most polluted cities worldwide. Out of the most 100 polluted cities all around the globe, 46 lie in India, and 42 are situated in China. Considering the aforementioned factors, the number of people afflicted with chronic obstructive pulmonary disease (COPD) is rising.

Medical & Pharmaceutical Gases & Equipment Market Drivers

Shooting up chronic illnesses is Anticipated to Boost Product Demand.

Jumping incidences of chronic illnesses is a major factor behind the growth of the medical & pharmaceutical gases and equipment market. According to the report, chronic maladies like heart attack and cancer are the biggest reason for increased mortality rates all over the globe. More than 600,000 people die from heart attacks in the US. Moreover, around 17-18 million lose their lives due to coronary heart diseases worldwide. Now as a major faction of the total world population is turning old these numbers are anticipated to witness a spike before long. It is estimated that are going to be 1-2 billion old people on this planet before long. All these factors are contributing their fair share to the growth of the aforementioned market.

Augmenting obesity and hospitalization ascribing to COVID-19 are Expected to Boost Product Demand.

COVID-19 is the prime reason behind the increased hospitalization in the last two years. Studies have found a direct link between COVID-19 and respiratory distress syndrome (ARDS) as the lungs are the most overwhelmed organ of the body. On another hand, the prevalence of chronic obstructive pulmonary disease (COPD) has become so common that every year India record more than 10 million cases. Likewise, the U.S. has recorded 16 million cases in 2021. Moreover, the budding trend of obesity due to poor intake and reduced activity is another reason driving the growth of the respective market.

Medical & Pharmaceutical Gases & Equipment Market Challenges

Health complications associated with medical gases are Anticipated to Hamper Market Growth.

Although incidences of serious health hitches associated with medical gases occur once in blue moon but still in many cases inhalation of gases like carbon dioxide and nitrous oxide can erupt many severe health complications which can be factor incongruent with the growth of medical & pharmaceutical gases & equipment market. CO2 exposure sets health hitches like tingling, asphyxia, uneven heartbeat, convulsion, and nuisances in motion. According to National Center for Biotechnology Information, the incidence of birth asphyxia in most developed countries accounts for less than 0.1% of newborn deaths. But, in developing countries, it ranged from 4.6/1000 to 7–26/1000 live births. More than 25.0% of the world's newborn deaths have occurred in Africa. Of those, birth asphyxia accounts for 24.0%. Moreover, excess nitrous oxide may give rise to nerve damage, coma, seizures, and loss of life in some cases.

Medical & Pharmaceutical Gases & Equipment Industry Outlook:

Product launches, mergers and acquisitions, joint ventures, and geographical expansions are key strategies adopted by players in the Medical & Pharmaceutical Gases & Equipment Market. Key companies in this market are-

Linde Group

BeaconMeadaes LLC

Air Liquide

BPR Medical

INOX Air products

Praxair

Gulf Cryo

Messer group

Taiyo Nippon Sanso

Atlas Copco

Recent Developments

On April 19, 2022, FDA approved GE Healthcare software that automates anesthesia and reduces greenhouse gas emissions during surgery. The software is cleared for use with GE Healthcare’s Aisys CS2 anesthesia delivery system.

On May 11, 2021, Sweden-based company “Atlas Copco” which develops and manufactures air compressors announced that it has successfully acquired North Carolina, United States-based company “Compressed air system Inc.” the financials of this deal were kept hidden but the acquisition is supposed to extend several advantages to Atlas Copco to enhance its overall reach to its customers.

On April 3, 2019, German industrial gas supplier “Messer Group” and British equity and investment company “CVC Capital partners” concluded an acquisition deal with “Linde.” Under the deal, Messer acquired many gases businesses which are located in America from Linde. The total value of this transaction was around $3.3 billion.

#Medical & Pharmaceutical Gases & Equipment Market share#Medical & Pharmaceutical Gases & Equipment Market size#Medical & Pharmaceutical Gases & Equipment Market forecast

0 notes

Text

How to choose the best dental chairs for posture and productivity

When a patient is having dental work done on them, the body of the patient must be supported in order for the dental chair to be considered an effective piece of medical equipment. During a process, the electrically powered chair is retractable, has a water line, a micromotor, and compressed air, and also comes equipped with all of the aforementioned features as standard equipment. The dental instruments in Malaysia come complete with a chair in which the dentist may sit while they operate on their patient. Each individual part that makes up a dental chair is intended to perform a certain function when the chair is assembled.

What to consider while buying a dental chair:

Air-water syringe:

This device may alternately deliver compressed air, water, or a mix of both while treating the patient. An air-water syringe is an example of this kind of equipment. During a procedure, it may also be utilized to clean the surface of the tooth being worked on.

Operator lights:

Lights for the operator Dental operator lights give the ideal lighting that is necessary for carrying out dental treatments in a comfortable manner. It is maintained between 30 and 50 inches away from the mouth of the patient. Thanks to the controls that come with it, dentists are able to adjust the intensity of the light as necessary.

Spittoon bowls:

Spittoon bowls are containers for patients' spittle to be collected while they are undergoing medical procedures. It is connected to a water pipe that forces the contents of the bowl toward the drain so that they may be flushed away and the bowl can remain clean.

X-ray viewer:

An X-ray viewer is a tool that is used for viewing radiographs in the dental field. Dentists examine and dissect these photos in order to better treat their patients.

Holder for disposable glasses:

Cups and glasses made of disposable materials by dental suppliers are stored on holders. The patient may drink water from these glasses and gargle with them while they are having dental work done. After that, they spat them out into the bowl of the spittoon.

Foot control motor:

This motor is utilized for the transmission of power to run the dental equipment, and it is controlled by a pedal. Foot control motors are also referred to as foot-operated motors. This dental chair with an electronic foot control has the same controls for operation as a dental chair with manual controls.

Additional things to keep in mind:

Appearance

It is possible to personalize dental chairs in terms of the colours, materials and finishes that you choose to complement your interior design. If you give careful consideration to the many types that are on the market, you will be able to choose a chair that looks completely natural within the setting of your clinic.

When you have determined the type that is most suitable for your needs, the next step is to ensure that the manufacturer has a diverse assortment of colour options and choices for the upholstery. This will provide the finishing touch.

When thinking about durability, it is important to take into account not only the kind of chair finish but also the design of the upholstery. It is essential to give careful consideration to the selection of a sturdy and long-lasting finish that is capable of withstanding abrasions, as well as corrosion, given that the chair base plate will be subjected to continuous attack from cleaning materials and equipment.

Comfort

When it comes to dental chair design and choosing dental equipment suppliers, patient comfort is the most important consideration. That's why you should "test before you buy" and get a firsthand look at what it's like to be a patient in the dentist's chair.

It is critical to provide comfort and reassurance to people who are already worried when they sit on a chair. Regardless of its size, a good dental chair will give you the support and padding you need to sit comfortably.

It is particularly important for patients undergoing lengthy specialty treatments to sit comfortably in a chair with enough padding and spacious armrests to reduce pressure points and support their bodies.

Ergonomic dental chairs and patient stools are important for patient health and practitioner productivity. A good dental chair boosts your immune system and business. With the preceding recommendations, choosing patient seats and operational stools is easy. For more information on dental instruments in Malaysia, contact AR Dental Supplies Sdn Bhd today!

0 notes