#Cellulose Esters Market Industry

Text

0 notes

Text

Acetic Acid Market to See Major Growth by 2029

Advance Market Analytics added research publication document on Worldwide Acetic Acid Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Acetic Acid market. The study provides valuable market size data for historical (Volume** & Value) from 2018 to 2022 which is estimated and forecasted till 2028*. Some are the key & emerging players that are part of coverage and have being profiled are Mitsubishi Chemical Corporation (Japan), British Petroleum (United Kingdom), DuPont (United States), Daicel Corporation (Japan), GNFC Limited (India), HELM AG (Germany), LyondellBasell Industries N.V. (Netherlands), PetroChina (China), Wacker Chemie (Germany), Saudi International Petrochemicals (Saudi Arabia).

Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://www.advancemarketanalytics.com/sample-report/37486-global-acetic-acid-market

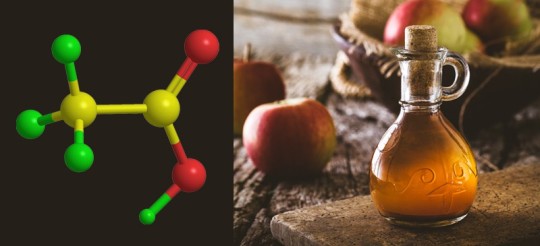

Acetic acid, also known as ethanoic acid, is an organic chemical compound which is recognized for giving vinegar its sour taste and pungent smell. Acetic acid is one of the simplest carboxylic acids and has the chemical formula CH3COOH. However, it is corrosive, and its vapor irritates the eyes, produces a burning sensation in the nose and can lead to a sore throat and lung congestion. Acetic acid is an essential chemical reagent and industrial chemical useful for the production of various synthetic fibers and other polymeric materials. These polymers are consist of polyethylene terephthalate which is mainly used in soft drink bottles; cellulose acetate, used mainly for photographic film; and polyvinyl acetate, used for wood glue. In households, diluted acetic acid is frequently used in descaling agents.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in Acetic Acid Market various segments and emerging territory.

Influencing Market Trend

Increasing Use of Ester Solvents in Paints & Coating Sector

Market Drivers

Rise in Demand for Vinyl Acetate Monomer

Increasing Demand from Textile & Packaging Industry

Opportunities:

The Untapped Market of Developing Countries

Challenges:

Fluctuations in Methanol Prices

Have Any Questions Regarding Global Acetic Acid Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/37486-global-acetic-acid-market Analysis by Type (Trickling Generation, Submerged Liquid Fermentation), Application (Vinyl Acetate Monomer (VAM), Purified Terephthalic Acid (PTA), Acetate Esters, Acetic Anhydride), End User (Plastics & Polymers, Food & Beverage, Inks)

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [Mitsubishi Chemical Corporation (Japan), British Petroleum (United Kingdom), DuPont (United States), Daicel Corporation (Japan), GNFC Limited (India), HELM AG (Germany), LyondellBasell Industries N.V. (Netherlands), PetroChina (China), Wacker Chemie (Germany), Saudi International Petrochemicals (Saudi Arabia),]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players

The regional analysis of Global Acetic Acid Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028.

Table of Content

Chapter One: Industry Overview

Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis

Chapter Three: Production Market Analysis

Chapter Four: Sales Market Analysis

Chapter Five: Consumption Market Analysis

Chapter Six: Production, Sales and Consumption Market Comparison Analysis

Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis

Chapter Eight: Competition Analysis by Players

Chapter Nine: Marketing Channel Analysis

Chapter Ten: New Project Investment Feasibility Analysis

Chapter Eleven: Manufacturing Cost Analysis

Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers

Read Executive Summary and Detailed Index of full Research Study @ https://www.advancemarketanalytics.com/reports/37486-global-acetic-acid-market

Highlights of the Report

• The future prospects of the global Acetic Acid market during the forecast period 2023-2028 are given in the report.

• The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report.

• The emerging technologies that are driving the growth of the market are highlighted in the report.

• The market value of the segments that are leading the market and the sub-segments are mentioned in the report.

• The report studies the leading manufacturers and other players entering the global Acetic Acid market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Acetic Acid Market#Acetic Acid Market Demand#Acetic Acid Market Trends#Acetic Acid Market Analysis#Acetic Acid Market Growth#Acetic Acid Market Share#Acetic Acid Market Forecast#Acetic Acid Market Challenges

0 notes

Text

Cost Efficiency in Dibutyl Phthalate Production: A Comprehensive Analysis

The latest report titled Dibutyl Phthalate Production Cost by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Dibutyl Phthalate.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/dibutyl-phthalate/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Dibutyl Phthalate production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Dibutyl Phthalate Production Process:

1. Dibutyl Phthalate Production Cost Using Phthalic anhydride: This report presents the detailed production methodology and cost analysis of Dibutyl Phthalate industrial production across Dibutyl Phthalate manufacturing plants. The reaction between phthalic anhydride and butanol in the presence of concentrated sulfuric acid as a catalyst gives dibutyl phthalate. The final product is purified using activated charcoal and vacuum distillation.

Request For Free Sample: https://procurementresource.com/cost-analysis/dibutyl-phthalate-production-using-phthalic-anhydride/requestsample

Product Definition:

Dibutyl phthalate belongs to the family of phthalate esters with a molecular formula C16H22O4 and is a clear, colorless liquid with a mild odor. It is most frequently used as a plasticizer, which means it is added to plastics to improve their flexibility, robustness, and workability. Due to its low volatility, the plastics to which it is added do not easily evaporate or escape, which adds to their long-term stability. It can also successfully blend with other plastics due to its high compatibility with a variety of polymers. It also has superior film-forming capabilities, which improve the consistency and aesthetics of plastic films. By lowering the melt viscosity of plastics, it increases their processability, making them simpler to mold and shape.

Market Drivers:

In the making of flexible polyvinyl chloride (PVC) products, dibutyl phthalate is primarily utilized as a plasticizer. It aids in increasing the flexibility, elongation, and workability of PVC. It also assists in making PVC materials more malleable so they can be molded and formed into different items. It is frequently used in the production of electrical cables, automobile parts, vinyl flooring, synthetic leather, and footwear. Other polymers and resins, such as cellulose derivatives, rubber, and lacquers, use DBP as a plasticizer. These materials become more flexible and durable, improving their suitability for uses including coatings, adhesives, and sealants. It is a flexible additive in the plastics and polymer sector thanks to its plasticizing capabilities and compatibility with a variety of polymers.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

Adapting the report to the country/region where you intend to establish your plant.

Adjusting the manufacturing capacity of the plant according to your needs

Customizing machinery suppliers and costs to meet your requirements.

Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

1 note

·

View note

Text

0 notes

Text

The Cellulosic Polymers Market is segmented by Type (Cellulose Esters, Cellulose Ethers, and Regenerated Cellulose) and Geography (Asia-Pacific, North America, Europe, and Rest of the World).

Download Free Sample Report - Cellulosic Polymers Market

0 notes

Text

Pharmaceutical Membrane Filtration Market Research Report, Growth, Analysis and Forecast 2029

Global Pharmaceutical Membrane Filtration Market, By Product (Filters, Systems, Accessories), Material (Polyethersulfone, Polyvinylidene Difluoride, Nylon Membrane Filters, Polytetrafluoroethylene, Mixed Cellulose Ester and Cellulose Acetate, Polycarbonate Track-Etched, Other Materials), Technique (Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis (RO), Ion Exchange), Application (Final Product Processing, Raw Material Filtration, Cell Separation, Water Purification, Air Purification) - Industry Trends and Forecast to 2029.

In the consistent Pharmaceutical Membrane Filtration market research report, industry trends are put together on macro level with which clients can figure out market landscape and possible future issues about Pharmaceutical Membrane Filtration industry. The scope of this market report include but is not limited to latest trends, market segmentation, new market entry, industry forecasting, future directions, opportunity identification, strategic analysis and planning, target market analysis, insights and innovation. The report presents with the CAGR value fluctuations for the specific forecasted period which helps decide costing and investment strategies. An influential Pharmaceutical Membrane Filtration market report brings precise and exact market research information that drives business into the right direction.

Key Players

Koninklijke Philips N.V. (Netherlands)

GENERAL ELECTRIC (U.S.)

Siemens (Germany)

Medtronic (Ireland)

Advanced Brain Monitoring, Inc. (U.S.)

Drägerwerk AG & Co. KGaA (U.S.)

Masimo (U.S.)

Blackrock Neurotech (U.S.)

Cadwell Industries, Inc (U.S.)

Browse More Info @ https://www.databridgemarketresearch.com/reports/global-pharmaceutical-membrane-filtration-market

The research studies entailed in the winning Pharmaceutical Membrane Filtration market report supports to estimate several important aspects that includes but are not limited to investment in a rising market, success of a new product, and expansion of market share. The strategies underlined here mainly consist of new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others that boost footprints in this market. Several other factors such as import, export, gross margin, price, cost, and consumption are also analyzed under the section of production, supply, sales and market status.

Key questions answered in the report:

Which product segment will grab a lion’s share?

Which regional market will emerge as a frontrunner in coming years?

Which application segment will grow at a robust rate?

Report provides insights on the following pointers:

Market Penetration: Comprehensive information on the product portfolios of the top players in the Pharmaceutical Membrane Filtration Market.

Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

Competitive Assessment: In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

Table Of Content

Part 01: Executive Summary

Part 02: Scope Of The Report

Part 03: Global Market

Part 04: Global Market Size

Part 05: Global Market Segmentation By Product

Part 06: Five Forces Analysis

More Reports:

Diuretic Drugs Market

Patient Engagement Technology Market

Healthcare Business Intelligence Market

Chinese Hamster Ovary cells (CHO) Market

Anti-cancer Drug Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

0 notes

Text

Cellulose Esters Market: Competitive Dynamics & Global Outlook 2032

0 notes

Text

Ethyl Acetate Market | Global Industry Size, Growth, Analysis & Forecast to 2030 | ChemAnalyst

According to ChemAnalyst report, “Ethyl Acetate Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, Ethyl Acetate market has witnessed a considerable growth as it reached 3.2 million tonnes in 2020 and is expected to grow a healthy global CAGR of 4.50% in the forecast period. Continuously growing demand of Ethyl Acetate for the production of various coating formulations such as urethanes, epoxies, cellulosics, acrylics, vinyl, and others by the paints and coatings industry is likely to boost the global Ethyl Acetate market over the next ten years. The production of Ethyl Acetate is highly related with safety concerns on the human health before it can be further manufactured, which further enhances the compliance standards.

Ethyl Acetate is an organic ester compound having the molecular formula C4H8O2. It is a flammable and colorless liquid, which has the characteristic of a sweet fruity smell. Ethyl Acetate, as also known as Ethyl Ethanoate, is an important commodity chemical used in various industrial and commercial applications. Ethyl Ethanoate is primarily used as solvents and diluents for cleaning mixtures, paints, coatings, varnishes, adhesives, lacquers and perfumes. It is extensively used as a component of nail polish removers and lacquer thinners. In laboratories, solvent of Ethyl Acetate is commonly used in thin-layer and column chromatography. Ethyl Ethanoate is manufactured by two methods including esterification of Ethanol and Acetic acid, and catalytic condensation of Acetaldehyde with Alkoxides. Although, in fruits it occurs naturally, where it is responsible for the taste and smell of the fruit.

Read Full Report Here: https://www.chemanalyst.com/industry-report/ethyl-acetate-market-632

The global Ethyl Acetate market on the basis of end-use industries can be segmented into paints and coatings, food and beverages, automotive, construction, packaging, and others. Global demand of Ethyl Acetate is dominated by the paints and coatings industry as it is widely used in paints and coatings as an activator and hardener. Exponentially rising demand of Ethyl Acetate by the paints and coatings industry is likely to bolster in the forecast period as well due to increasing construction activities across the globe. Increasing demand of Ethyl Acetate in the food and beverage industry is expected to rise in the near future as it is acceptable for food applications like artificial flavor enhancer in confectionery items and decaffeinating tea and coffee. In emerging economies, the initiatives of government for the construction of commercial buildings, including hotels and resorts, are augmenting the demand for floor coatings, which will further boost the global market of Ethyl Acetate in upcoming years. Rising demand of Ethyl Acetate solvents by the packaging industries to manufacture flexographic and rotogravure inks, will fuel the global Ethyl Acetate market in the next few years. Owing to the robust demand of Ethyl Acetate by the pharmaceutical industry is expected to drive the global market of Ethyl Acetate in the future.

The outbreak of COVID-19 had a negative impact on the global Ethyl Acetate market. Several industries including paint and coatings, construction, printing, packaging, aerospace, and others were drastically affected due to interruptions in the global supply chain. There was a severe decline in the sales and demand of Ethyl Acetate solvents as many production units halted their operations during the first half of 2020. Once the restrictions imposed by the leading authorities are uplifted, major end-user industries including paints and coating and flexible packaging, will accelerate the demand of Ethyl Acetate around the world by the end of the year.

Read Free Sample Report Online: https://www.chemanalyst.com/ChemAnalyst/RequestForm

Among different regions, Asia Pacific region holds the major share of the global demand of Ethyl Acetate. Rapidly growing urbanization and income levels in populous countries like China and India, is driving the dominance of global Ethyl Acetate market in the Asia Pacific region and is forecasted to grow significantly until 2030. Rising construction activities in the Asia Pacific region will further augment the demand of Ethyl Acetate in the future. Expansion of major end-user industries including automotive, flexible packaging, paints and coatings is another factor driving the demand of Ethyl Acetate in the Asia Pacific region.

Some of the major players operating in Ethyl Acetate market include Celanese Corporation, Eastman Chemical Company, INEOS Capital Limited., Celanese Corporation, Jubilant Life Sciences Limited, Sipchem, Lonza, Sekab, PT. Indo Acidatama Tbk., Solvay, Merck KGaA, Shandong Jinyimeng Group Co. Ltd., DAICEL CORPORATION, KAI CO., LTD., and Others.

“Rapidly growing demand for Ethyl Acetate by the flourishing paints and coatings industry as well as flexible packaging industry across the globe is likely to boost the global Ethyl Acetate market in the forecast period until 2030. Initiatives of the government for the construction of commercial buildings and building of smart cities in the Asia Pacific region, will further augment the market growth of Ethyl Acetate in the next few years. As China is the world's largest producer of automobiles, rising demand of Ethyl Acetate solvents by the automotive industry will flourish the global Ethyl Acetate market in upcoming years.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

About Us

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

420 Lexington Avenue,

Suite 300, New York,

NY, United States, 10170

Call:- +1 3322586602

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

0 notes

Text

Cellulose Derivative Market Size, Share, Demand, Growth & Trends by 2032

Cellulose Derivative Market forecasted to registering 5.3% CAGR during the forecast period (2022-2032) and projected to reach US$ 9,844 Million by 2032. Cellulose is natural polymer present in plants, and cellulose derivative is produced from the pulp. The pulp is basically a fibrous material yielded after separation of cellulose fibres from fibre crops, waste paper or from wood. Naturally, the cellulose derivatives are water insoluble but with chemical process and alterations of the molecules, they are modified into water-insoluble cellulose derivatives.

These water-insoluble cellulose derivatives find various applications such as in ceramics. Methylcellulose, cellulose derivative offers uniform thickness, better flow properties, and thermal gelation. Also, Cellulose ethers and cellulose esters which are also cellulose derivatives are widely used in pharmaceutical industries for formulations of health care products.

Request for PDF Sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-2470

Other pharmaceutical uses of cellulose derivatives include coating processes, mucoadhesive and bioadhesive drug delivery systems, osmotic drug delivery systems etc. Cellulose derivatives are also used in concrete mixtures as an additive, thus protects the water quality throughout construction. The cellulose derivatives are manufactured by various grades depending on the use such as, food grade, pharmaceutical grades, constructions grades etc.

Cellulose derivative finds applications even in soaps and shampoos for producing long lasting foam. The cellulose derivatives market is expected to expand significantly during the forecast period due to increasing consumption in the diverse application.

Global Cellulose Derivative Market: Drivers and Restraints

The global cellulose derivative market is primarily driven by the increasing demand from pharmaceutical, personal care, and cosmetic industries. Cellulose derivatives offer wide properties such as stabilization, emulsification, reversible thermal gelation etc.

These properties are enormously required in the food industry and increasing demand for these functional additive properties propels the global cellulose derivatives market.

However, the stringent regulations for cellulose derivative might impact the growth of cellulose derivative market.

Global Cellulose derivative Market: Region wise Outlook

The global cellulose derivative market is divided into seven regions, namely North America, Latin America, Asia Pacific excluding Japan (APEJ), Western Europe, Eastern Europe, Japan and Middle East and Africa (MEA). APEJ holds the major share in the global cellulose derivative market due increasing consumption in various application such as food industry, construction and pharmaceutical industries.

Followed by APEJ is North America and Europe and are expected to grow relatively at a higher CAGR during the forecast period. The global cellulose derivative market is anticipated to expand at a double digit CAGR growth due to expansion of end use industries during the forecast period.

Browse Full Report: https://www.futuremarketinsights.com/reports/cellulose-derivative-market

Global Cellulose Derivative Market: Key Players

Some of the key players identified in the global cellulose derivative market includes:

Shin-Etsu Chemical Co., Ltd

LOTTE Fine Chemical

Samsung Fine Chemicals

Daicel Corporation.

Akzo Nobel N.V. (Performance additives)

Ashland Inc.

SE Tylose GmbH & Co. KG

CP Kelco

Shandong Head Europe BV

Sichuan Nitrocell Co Ltd

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geography, technology and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Global Cellulose Derivative Market: Segmentation

On the basis of cellulose derivative type:

Methyl Cellulose Derivatives

Carboxymethyl Cellulose Derivatives

Hydroxyethyl Cellulose Derivatives

Ethyl Cellulose Derivatives

Other Cellulose Derivative Types

On the basis of cellulose derivatives grades:

Food Grade Cellulose Derivatives

Pharmaceutical Grade Cellulose Derivatives

On the basis of end use:

Food Industry

Pharmaceutical Industry

Personal Care

Construction

Paint Industry

Others

0 notes

Text

0 notes

Text

Biodiesel Market - Forecast (2023 - 2028)

Biodiesel Market size is forecast to reach $50.60 billion by 2026, after growing at a CAGR of 5.3% during 2021-2026. There are four principal methods to make biodiesel, direct use, and blending, microemulsions, thermal cracking (pyrolysis) and transesterification, which changes oil and fats into fatty acid methyl esters. Biodiesel is composed of renewable feedstocks such as vegetable oils, animal fats. Biodiesel produced from Animal Tallow tends to crystallize out at much higher temperatures than biodiesel derived from plant oils. Biodiesel is capable to reduce exhaust emissions as compared to petroleum diesel fuel. It is majorly used in Automotive, Aerospace, Industrial, Marine, and Agriculture. The key factors for the development of this market are reducing storage concerns with stability and transportation issues with the great cost of delivered fuel compared to fossil fuels, it can decrease the ecological nuisances such as global warming, the greenhouse effect, and pollution. Cellulosic ethanol is one of the fastest-rising alternative fuels produce from biomass. Biodiesel is typically used as a diesel blending component at levels up to 20% by volume. Life-cycle analysis indicates that the use of biodiesel can help displace imported petroleum in the United States, and has the potential to displace 5% or more of petroleum diesel over the next decade. Growing demand for Biodiesel in commercial cars to put back crude oil is predicted to have a certain growth in the industry. Biodiesel fuel blends on oil dilution is one option currently being researched as a trail to energy diversity and decreased petroleum dependence in the transportation sector.

Request Sample : https://tinyurl.com/5u8hbyuy

#Biodiesel Market price#Biodiesel Market size#Biodiesel Market share#Biodiesel Market forecast#Biodiesel Market trends

0 notes

Text

Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuel Global Market to 2033

New Post has been published on https://petnews2day.com/pet-industry-news/pet-financial-news/biobased-chemicals-materials-polymers-plastics-paints-coatings-and-fuel-global-market-to-2033/

Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuel Global Market to 2033

Company Logo

Dublin, Nov. 09, 2022 (GLOBE NEWSWIRE) — The “The Global Market for Biobased Chemicals, Materials, Polymers, Plastics, Paints & Coatings and Fuels to 2033” report has been added to ResearchAndMarkets.com’s offering.

Biobased materials refer to products that mainly consist of a substance (or substances) derived from living matter (biomass) and either occur naturally or are synthesized, or it may refer to products made by processes that use biomass. Materials from biomass sources include bulk chemicals, platform chemicals, solvents, polymers, and biocomposites.

The many processes to convert biomass components to value-added products and fuels can be classified broadly as biochemical or thermochemical.

In addition, biotechnological processes that rely mainly on plant breeding, fermentation, and conventional enzyme isolation also are used. New bio-based materials that may compete with conventional materials are emerging continually, and the opportunities to use them in existing and novel products are explored in this publication.

There is growing consumer demand and regulatory push for bio-based chemicals, materials, polymers, plastics, paints, coatings and fuels with high performance, good recyclability and biodegradable properties to underpin transition towards more sustainable manufacturing and products.

Contents include:

In-depth market analysis of bio-based chemical feedstocks, biopolymers, bioplastics, natural fibers and lignin, biofuels and bio-based coatings and paints.

Global production capacities, market volumes and trends,current and forecast to 2033.

Analysis of bio-based chemical including 11-Aminoundecanoic acid (11-AA), 1,4-Butanediol (1,4-BDO), Dodecanedioic acid (DDDA), Epichlorohydrin (ECH), Ethylene, Furan derivatives, 5-Chloromethylfurfural (5-CMF), 2,5-Furandicarboxylic acid (2,5-FDCA), Furandicarboxylic methyl ester (FDME), Isosorbide, Itaconic acid, 5 Hydroxymethyl furfural (HMF), Lactic acid (D-LA), Lactic acid – L-lactic acid (L-LA), Lactide, Levoglucosenone, Levulinic acid, Monoethylene glycol (MEG), Monopropylene glycol (MPG), Muconic acid, Naphtha, 1,5-Pentametylenediamine (DN5), 1,3-Propanediol (1,3-PDO), Sebacic acid and Succinic acid.

Analysis of synthetic bio-polymers and bio-plastics market including Polylactic acid (Bio-PLA), Polyethylene terephthalate (Bio-PET), Polytrimethylene terephthalate (Bio-PTT), Polyethylene furanoate (Bio-PEF), Polyamides (Bio-PA), Poly(butylene adipate-co-terephthalate) (Bio-PBAT), Polybutylene succinate (PBS) and copolymers, Polyethylene (Bio-PE), Polypropylene (Bio-PP)

Analysis of naturally produced bio-based polymers including Polyhydroxyalkanoates (PHA), Polysaccharides, Microfibrillated cellulose (MFC), Cellulose nanocrystals, Cellulose nanofibers, Protein-based bioplastics, Algal and fungal.

Analysis of market for biofuels.

Analysis of types of natural fibers including plant fibers, animal fibers including alternative leather, wool, silk fiber and down and polysaccharides.

Markets for natural fibers, including composites, aerospace, automotive, construction & building, sports & leisure, textiles, consumer products and packaging.

Production capacities of lignin producers.

In depth analysis of biorefinery lignin production.

Analysis of the market for bio-based, sustainable paints and coatings.

Analysis of types of bio-coatings and paints market. Including Alkyd coatings, Polyurethane coatings, Epoxy coatings, Acrylate resins, Polylactic acid (Bio-PLA), Polyhydroxyalkanoates (PHA), Cellulose, Rosins, Biobased carbon black, Lignin, Edible coatings, Protein-based biomaterials for coatings, Alginate etc.

Profiles of over 800 companies.

Story continues

Key Topics Covered:

1 EXECUTIVE SUMMARY

2 RESEARCH METHODOLOGY

3 THE GLOBAL PLASTICS MARKET

3.1 Global production

3.2 The importance of plastic

3.3 Issues with plastics use

3.4 Policy and regulations

3.5 The circular economy

3.6 Conventional polymer materials used in packaging

3.6.1 Polyolefins: Polypropylene and polyethylene

3.6.2 PET and other polyester polymers

3.6.3 Renewable and bio-based polymers for packaging

3.7 Comparison of synthetic fossil-based and bio-based polymers

3.8 End-of-life treatment of bioplastics

4 BIO-BASED CHEMICALS

4.1 Types

4.2 Production capacities

4.3 Bio-based adipic acid

4.4 11-Aminoundecanoic acid (11-AA)

4.5 1,4-Butanediol (1,4-BDO)

4.6 Dodecanedioic acid (DDDA)

4.7 Epichlorohydrin (ECH)

4.8 Ethylene

4.9 Furfural

4.10 5-Hydroxymethylfurfural (HMF)

4.11 5-Chloromethylfurfural (5-CMF)

4.12 2,5-Furandicarboxylic acid (2,5-FDCA)

4.13 Furandicarboxylic methyl ester (FDME)

4.14 Isosorbide

4.15 Itaconic acid

4.16 3-Hydroxypropionic acid (3-HP)

4.17 5 Hydroxymethyl furfural (HMF)

4.18 Lactic acid (D-LA)

4.19 Lactic acid – L-lactic acid (L-LA)

4.20 Lactide

4.21 Levoglucosenone

4.22 Levulinic acid

4.23 Monoethylene glycol (MEG)

4.24 Monopropylene glycol (MPG)

4.25 Muconic acid

4.26 Naphtha

4.27 Pentamethylene diisocyanate

4.28 1,3-Propanediol (1,3-PDO)

4.29 Sebacic acid

4.30 Succinic acid (SA)

5 BIOPOLYMERS AND BIOPLASTICS

5.1 Bio-based or renewable plastics

5.1.1 Drop-in bio-based plastics

5.1.2 Novel bio-based plastics

5.2 Biodegradable and compostable plastics

5.2.1 Biodegradability

5.2.2 Compostability

5.3 Advantages and disadvantages

5.4 Types of Bio-based and/or Biodegradable Plastics

5.5 Market leaders by biobased and/or biodegradable plastic types

5.6 Regional/country production capacities, by main types

5.6.1 Bio-based Polyethylene (Bio-PE) production capacities, by country

5.6.2 Bio-based Polyethylene terephthalate (Bio-PET) production capacities, by country

5.6.3 Bio-based polyamides (Bio-PA) production capacities, by country

5.6.4 Bio-based Polypropylene (Bio-PP) production capacities, by country

5.6.5 Bio-based Polytrimethylene terephthalate (Bio-PTT) production capacities, by country

5.6.6 Bio-based Poly(butylene adipate-co-terephthalate) (PBAT) production capacities, by country

5.6.7 Bio-based Polybutylene succinate (PBS) production capacities, by country

5.6.8 Bio-based Polylactic acid (PLA) production capacities, by country

5.6.9 Polyhydroxyalkanoates (PHA) production capacities, by country

5.6.10 Starch blends production capacities, by country

5.7 SYNTHETIC BIO-BASED POLYMERS

5.7.1 Polylactic acid (Bio-PLA)

5.7.1.1 Market analysis

5.7.1.2 Producers

5.7.2 Polyethylene terephthalate (Bio-PET)

5.7.2.1 Market analysis

5.7.2.2 Producers

5.7.3 Polytrimethylene terephthalate (Bio-PTT)

5.7.3.1 Market analysis

5.7.3.2 Producers

5.7.4 Polyethylene furanoate (Bio-PEF)

5.7.4.1 Market analysis

5.7.4.2 Comparative properties to PET

5.7.4.3 Producers

5.7.5 Polyamides (Bio-PA)

5.7.5.1 Market analysis

5.7.5.2 Producers

5.7.6 Poly(butylene adipate-co-terephthalate) (Bio-PBAT)

5.7.6.1 Market analysis

5.7.6.2 Producers

5.7.7 Polybutylene succinate (PBS) and copolymers

5.7.7.1 Market analysis

5.7.7.2 Producers

5.7.8 Polyethylene (Bio-PE)

5.7.8.1 Market analysis

5.7.8.2 Producers

5.7.9 Polypropylene (Bio-PP)

5.7.9.1 Market analysis

5.7.9.2 Producers

5.8 NATURAL BIO-BASED POLYMERS

5.8.1 Polyhydroxyalkanoates (PHA)

5.8.1.1 Types

5.8.1.2 Synthesis and production processes

5.8.1.3 Market analysis

5.8.1.4 Commercially available PHAs

5.8.1.5 Markets for PHAs

5.8.1.6 Producers

5.8.2 Polysaccharides

5.8.2.1 Microfibrillated cellulose (MFC)

5.8.2.2 Cellulose nanocrystals

5.8.2.3 Cellulose nanofibers

5.8.2.4 Bacterial Nanocellulose (BNC)

5.8.3 Protein-based bioplastics

5.8.3.1 Types, applications and producers

5.8.4 Algal and fungal

5.8.4.1 Algal

5.8.4.2 Mycelium

5.8.5 Chitosan

5.8.6 Microplastics alternatives

5.9 PRODUCTION OF BIOBASED AND SUSTAINABLE PLASTICS, BY REGION

5.9.1 North America

5.9.2 Europe

5.9.3 Asia-Pacific

5.9.3.1 China

5.9.3.2 Japan

5.9.3.3 Thailand

5.9.3.4 Indonesia

5.9.4 Latin America

5.10 MARKET SEGMENTATION OF BIOPLASTICS

5.10.1 Packaging

5.10.2 Consumer products

5.10.3 Automotive

5.10.4 Building & construction

5.10.5 Textiles

5.10.6 Electronics

5.10.7 Agriculture and horticulture

5.11 BIO-BASED CHEMICALS, BIOPOLYMERS AND BIOPLASTICS COMPANY PROFILES (325 company profiles)

6 NATURAL FIBERS

6.1 Manufacturing method, matrix materials and applications of natural fibers

6.2 Advantages of natural fibers

6.3 Commercially available next-gen natural fiber products

6.4 Market drivers for next-gen natural fibers

6.5 Challenges

6.6 Plants (cellulose, lignocellulose)

6.6.1 Seed fibers

6.6.1.1 Cotton

6.6.1.2 Kapok

6.6.1.3 Luffa

6.6.2 Bast fibers

6.6.2.1 Jute

6.6.2.2 Hemp

6.6.2.3 Flax

6.6.2.4 Ramie

6.6.2.5 Kenaf

6.6.3 Leaf fibers

6.6.3.1 Sisal

6.6.3.2 Abaca

6.6.4 Fruit fibers

6.6.4.1 Coir

6.6.4.2 Banana

6.6.4.3 Pineapple

6.6.5 Stalk fibers from agricultural residues

6.6.5.1 Rice fiber

6.6.5.2 Corn

6.6.6 Cane, grasses and reed

6.6.6.1 Switch grass

6.6.6.2 Sugarcane (agricultural residues)

6.6.6.3 Bamboo

6.6.6.4 Fresh grass (green biorefinery)

6.6.7 Modified natural polymers

6.6.7.1 Mycelium

6.6.7.2 Chitosan

6.6.7.3 Alginate

6.7 Animal (fibrous protein)

6.7.1 Wool

6.7.1.1 Alternative wool materials

6.7.1.2 Producers

6.7.2 Silk fiber

6.7.2.1 Alternative silk materials

6.7.3 Leather

6.7.3.1 Alternative leather materials

6.7.4 Fur

6.7.4.1 Producers

6.7.5 Down

6.7.5.1 Alternative down materials

6.8 MARKETS FOR NATURAL FIBERS

6.8.1 Composites

6.8.2 Applications

6.8.3 Natural fiber injection moulding compounds

6.8.3.1 Properties

6.8.3.2 Applications

6.8.4 Non-woven natural fiber mat composites

6.8.4.1 Automotive

6.8.4.2 Applications

6.8.5 Aligned natural fiber-reinforced composites

6.8.6 Natural fiber biobased polymer compounds

6.8.7 Natural fiber biobased polymer non-woven mats

6.8.7.1 Flax

6.8.7.2 Kenaf

6.8.8 Natural fiber thermoset bioresin composites

6.8.9 Aerospace

6.8.9.1 Market overview

6.8.10 Automotive

6.8.10.1 Market overview

6.8.10.2 Applications of natural fibers

6.8.11 Building/construction

6.8.11.1 Market overview

6.8.11.2 Applications of natural fibers

6.8.12 Sports and leisure

6.8.12.1 Market overview

6.8.13 Textiles

6.8.13.1 Market overview

6.8.13.2 Consumer apparel

6.8.13.3 Geotextiles

6.8.14 Packaging

6.8.14.1 Market overview

6.9 NATURAL FIBERS GLOBAL PRODUCTION

6.9.1 Overall global fibers market

6.9.2 Plant-based fiber production

6.9.3 Animal-based natural fiber production

6.10 NATURAL FIBER COMPANY PROFILES (178 company profiles)

7 LIGNIN

7.1 INTRODUCTION

7.2 LIGNIN PRODUCTON PROCESSES

7.3 MARKETS FOR LIGNIN

7.4 COMPANY PROFILES (75 company profiles)

8 BIOBASED AND RENEWABLE FUELS

8.1 BIOFUELS

8.2 ELECTROFUELS (E-FUELS)

8.3 GREEN AMMONIA

8.4 COMPANY PROFILES (114 company profiles)

9 BIO-BASED PAINTS AND COATINGS

9.1 The global paints and coatings market

9.2 Bio-based paints and coatings

9.3 Challenges using bio-based paints and coatings

9.4 Types of bio-based coatings and materials

9.5 Market for bio-based paints and coatings

9.6 Company profiles (130 company profiles)

10 REFERENCES

For more information about this report visit https://www.researchandmarkets.com/r/dbzix6

CONTACT: CONTACT: ResearchAndMarkets.com Laura Wood,Senior Press Manager [email protected] For E.S.T Office Hours Call 1-917-300-0470 For U.S./ CAN Toll Free Call 1-800-526-8630 For GMT Office Hours Call +353-1-416-8900

0 notes

Text

Children's Suits & Ensembles Market Expected To Achieve Lucrative Growth By 2030

The global children’s suits & ensembles market size was estimated to reach USD 4,918.9 million by 2028, registering a CAGR of 2.9% from 2022 to 2028 according to a new report by Grand View Research, Inc. This can be attributed to the strong growth scenario in the Asia Pacific market, mainly due to the population growth coupled with rising per capita expenditure. However, the market growth of the children’s suits & ensembles market is hindered by the import and market access barriers, mostly due to stringent government trade laws and political opportunism.

The COVID-19 had a negative impact on the global children’s suits & ensembles market. Various countries imposed restrictions and lockdown to curb the spread of disease, which subsequently affected the market activities thus, slowing down the children’s suits & ensembles market. Restricted or reduced sales, plummeted trade, and curtailed manufacturing activities during the lockdown resulted in declined sales and demand across the globe. However, market is anticipated to witness positive demand and healthy growth in the coming years on the account of relaxed restrictions and resumed trade along with manufacturing activities.

Market analysis, based on the fiber segment illustrated, that the market revenue share was substantially contributed by the polyester fiber segment. Polyester occupied the global market revenue share of more than 40.0% in 2021. Polyester is a synthetic fiber which is derived from petroleum industry. The is highly non-degradable product and is a serious environmental pollutant. It is a polymer containing ester as a functional group. Its characteristics are highly favorable by the clothing manufacturers in the industry. It is durable, water resistant, wear and tear tolerant, and versatile, making it popular fabric in the apparel industry. This is attributed to the higher market share of the segment.

Online segment is anticipated to register CAGR of 3.5% from 2022 to 2028. Online segment is expected to witness promising growth development due to the expansion of online retail giant and emergence of new online retailers plus company-owned websites. Moreover, the COVID-19 pandemic augmented online channel decade of growth in a single year in apparel industry, as the global brand manufacturers chose to launch online shopping websites to make up the loss occurred in sales due to the pandemic restrictions.

Global children’s suits & ensembles market was dominated by boy’s segment and contributed market revenue share of over 55.0% in 2021. Formal gathering and party, wedding, festivals, etc. at such occasions boys require to dress up in formal clothes, especially suits and ensembles. Higher population of the boys compared to the girls is also credited for the higher market share. Moreover, elevated demand from the end user segment for suits and ensemble products accounts for top market share contribution.

Europe dominated the children’s suits & ensembles market revenue share, contributing more than 30.0% in 2021. Suits and ensemble type of clothes is already existing product, with higher awareness in the European region. Kid’s wear industry is developed and established in the region along with the strong presence of key players with extensive distribution through online as well as offline channels. This contributes to the highest market revenue share of the region, in 2021. Moreover, consumer disposable income and per capita spending on clothing and apparel in the region accounts for the top market share.

Request a free sample copy or view report summary: Children’s Suits & Ensembles Market Report

Children’s Suits & Ensembles Market Report Highlights

Asia Pacific is expected to register highest growth during the forecast period, with a CAGR of 3.7%. Increasing population, developments in retail sector, and increasing disposable income are the factors expected to drive the growth

Cellulosic fiber segment expected to witness the highest CAGR of 3.8% from 2022 to 2028. The demand for the cellulosic fibers is expected to skyrocket in the future as demand for green technology and sustainable solutions is increasing

Online distribution channel is expected to register CAGR of 3.5% from 2022 to 2028. Consumers inclination towards convenience and comfort has led to increasing utilization of online transaction platforms

Girls segment of end user is expected to register CAGR of 3.1% from 2022 to 2028. The demand for girls’ apparel in Asia Pacific is increasing at tremendous rate due to rising adoption of western lifestyle

Children’s Suits & Ensembles Market Segmentation

Grand View Research has segmented the global children’s suits & ensembles market based on the fiber, distribution channel, end user, and region:

Children’s Suits & Ensembles Fiber Outlook (Revenue, USD Million, 2017 - 2028)

Cotton

Polyester

Cellulosic

Others

Children’s Suits & Ensembles Distribution Channel Outlook (Revenue, USD Million, 2017 - 2028)

Offline

Online

Children’s Suits & Ensembles End User Outlook (Revenue, USD Million, 2017 - 2028)

Girls

Boys

Children’s Suits & Ensembles Regional Outlook (Revenue, USD Million, 2017 - 2028)

North America

U.S.

Europe

Germany

France

U.K.

Asia Pacific

China

India

Central & South America

Brazil

Middle East & Africa

South Africa

List of Key Players of Children’s Suits & Ensembles Market

Zara SA

Marks & Spencer Plc.

Hugo Boss

Calvin Klein

NEXT

Giorgio Armani S.p.A.

Ralph Lauren Corp.

Moss Bros Group Plc.

Punto Fa, S.L.

0 notes

Text

Covid-19 Pandemic Has Negatively Impacted Hydroxyethyl Cellulose (Hec) Market

The global hydroxyethyl cellulose market size is expected to reach USD 1.2 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 4.5% from 2022 to 2030. The growth is majorly driven by rising demand for cellulose products in water-borne architectural paints and coatings, textile, personal care and cosmetics, and other industrial applications. The cellulose esters market is anticipated to be driven by growing demand in the paper and paperboard, textile, photographic films, and food and beverages industries. The production process of HEC begins with cellulose as a raw material in the form of sheets and rolls, which are treated with sodium hydroxide solution and reacted with ethylene oxide.

Hydroxyethyl ester of cellulose is majorly used as a thickening agent and water binder in several industry applications including pharmaceutical formulations, adhesives, building materials, and personal use care products. The building materials application segment accounted for more than 14.0% of the revenue share in 2021 and is estimated to witness a significant growth rate in the near future. There is a clear growth in the consumption of HEC products due to the increasing utility of these products in building materials, along with consumer preference for sustainable products.

Gain deeper insights on the market and receive your free copy with TOC now @: Hydroxyethyl Cellulose Market Report

Increasing consumption in building materials coupled with rising demand from the cosmetics industry is expected to boost the market growth. The COVID-19 pandemic has negatively impacted the market, considering demand-supply restrictions and the shutdown of non-essential product warehouses. In 2020, the prices of cellulose witnessed a rise owing to low inventory levels and the shutdown of production plants. Low levels of inventory with recovering demand, challenges in container logistics, and reduced supply due to the shutdown of manufacturing plants negatively impacted the market amid the COVID-19 pandemic.

#Hydroxyethyl Cellulose Market Size & Share#Hydroxyethyl Cellulose Market Latest Trends#Hydroxyethyl Cellulose Market Growth Forecast#COVID-19 Impacts On Hydroxyethyl Cellulose Market#Hydroxyethyl Cellulose Market Revenue Value

0 notes

Text

Growing Importance of Chemicals Used In Pharma Industry!

Those who are familiar with the pharmaceutical sector will be aware that the demand for benzyl benzoate manufacturers in India and Meglumine has grown significantly. In fact, benzyl benzoate is recognized by the World Health Organization as a vital medication for the human health system.

Let us guide you through the two very popular chemicals used widely in pharmaceuticals.

Benzyl benzoates

An ester molecule called benzyl benzoate is created by condensing benzoate and benzyl alcohol. It is frequently utilised in the pharmaceutical industry and is thought to be essential for treating lice and scabies.

Benzyl benzoates are used as plasticisers and in textiles for non-medical purposes. The substance is also employed as a dye carrier, cellulose derivative solvent, and mosquito deterrent.

Meglumine

Meglumine is an organic base that is employed in parenteral and solid oral formulations as a pH-adjusting and solubilising agent. In the presence of an acidic pH, many APIs quickly ionise, which reduces absorption. The solution to this issue is to use meglumine, a basic agent that aids in the dissolution of such APIs. Meglumine is produced in our laboratory, which EXCiPACT, ISO, and GMP accredit. We also offer thorough regulatory documentation, such as risk assessment documents for elemental and nitrosamine impurities used in pharmaceutical applications.

Meglumine is widely utilized in the pharmaceutical sector for a number of reasons, including:

Meglumine is an organic base that is used to change the pH. In solid orals and parenteral formulations, it serves as a solubilizing agent.

Let’s talk about Benzyl Benzoate - A popular chemical used in the pharmaceutical and laundry industry!

The main element driving the growth of benzyl benzoate's global market is its expanding use in medicinal and, flavour & fragrance applications.

Additionally, the market for benzoate will continue to expand in the upcoming years due to the leading players' increased emphasis on research and development (which includes specialization in the development of new products and other innovative tactics).

Industrial-grade benzyl benzoate will control the greatest share of the product type segment if the trend holds steady during the forecast period. Additionally, the industrial-grade market is anticipated to post the largest revenue growth.

The benzyl benzoate market is divided into pharmaceuticals based on end-use applications (in scabies therapy). Due to the thriving pharmaceutical business, the segment is anticipated to experience strong incremental growth in the approaching years.

Among the numerous application sectors, the textile segment is projected to be significant and sustain a constant trend. Benzoyl benzoate is a common sealant, levelling agent, and dye carrier in the textile industry. Furthermore, a rising CAGR is expected for the plasticiser segment in the near future, which will see the highest growth.

In fact, laundry detergent also uses benzenesulfonic acid salts as surfactants, including sodium benzenesulfonate (Ludigol) and monoethanolamine benzenesulfonate. Besylate (INN) or besylates are the names of various medicinal substances made as benzenesulfonate salts (USAN).

Manufacturers all across the world, including Finar, are getting ready for this anticipated increase and striving to develop the tools and human resources needed to fulfil demand and supply.

Finar is known to be the finest manufacturer of all three chemicals, offering the best quality. If you are looking for trusted benzene sulfonic acid manufacturers in in India or benzyl benzoate manufacturers, look no further!

0 notes