Text

Keynote at Europump Annual Meeting: CIRPASS project - defining the framework for the EU’s Digital Product Passport (DPP)

Europump (the European Pump Association) which represents 15 National Associations across the continent of Europe has now finalised the programme of talks and presentations for its 2024 Annual Meeting, which takes place in Windsor, UK from 22nd – 24th May.

Hosted by the British Pump Manufacturers Association (BPMA) and sponsored by WEG – a world leader in motor, drive, and asset management systems technology – this key event for the international pump sector will deliver a comprehensive programme of meetings and presentations that offers commercial value at a practical level for Europe’s pump manufacturers and suppliers.

In addition to the sessions dedicated to the activities of the various Europump Commissions – Technical, Standards, Marketing, SME – a complement of invited speakers will share their knowledge and expertise on a range of topical issues.

Carolynn Bernier, Research Engineer at CEA

As well as the four Keynote presentations already announced, the team behind this prestigious gathering of pump executives, is delighted to now welcome Carolynn Bernier, Research Engineer at CEA, and the consortium coordinator of the CIRPASS project, in charge of defining the framework for the EU’s Digital Product Passport (DPP).

Carolynn holds a degree in Computer Engineering from the University of Toronto and a PhD in Microelectronics from the National Polytechnic Institute of Grenoble. Her background is in integrated circuit design for IoT wireless communications and her current research activities include smart embedded perception systems, and digital technologies for the circular economy and sustainable electronics.

With Digital Product Passports (DPP) expected to come into force by 2027, and gradually expanded to a wide range of product groups, including pumps and their related systems, Carolynn’s presentation, entitled ‘Digital Product Passports – the current state of play’ will provide delegates with important updates and an increased understanding of DPP deployment.

It will take place on the morning of 23rd May, ahead of the presentation by Mike Otten, Director, Edge & Intelligence, Xylem, which will address the impact of Artificial Intelligence for the pump manufacturing industry, and how to harness the power of Digital Twins and Generative AI for an evolution of the sector.

During the afternoon, as part of the Marketing and SME Commission Updates, Kiran Ahmed, Lead Economist, Oxford Economics, will present the key findings from the 2024 World Pump Report, which will have been published just weeks before the event.

Then, on the morning of Friday 24th May, Daniel Godinho, Sustainability and Corporate Affairs Director, WEG, in tandem with Martin Brand, Engineering Director, WEG, will offer a fascinating talk on the ethical, ecological, and commercial benefits of sustainability. This will be directly followed by Stephen Phipson CBE, Chief Executive, Make UK, who will provide an overview of the political arena in the UK and its impact on the manufacturing sector both at home and abroad.

Commenting on the impressive line-up of Keynote Speakers, Europump’s Secretary General, Lisa Kretschmann, said: “We are delighted to have secured the engagement of such renowned experts, who’s wisdom and insight will be of immense value to our audience of senior pump executives. The overall programme of meetings, presentations and discussions ensure this is a must-attend event for all those looking to navigate their way through the complexities of pump engineering over the coming months and years. As such, I would encourage anyone not already booked in to the event to do so straight away.”

Full details on the event, including further information on the venue, its location and travel arrangements can be found on the dedicated website. The online booking system is simple to use, and a promotional video, illustrating all aspects of the event is also available to view on the site - www.Europump2024.com.

Read the full article

0 notes

Text

New video from Sulzer: Connecting the pipes to the pump

Read the full article

0 notes

Text

Invertek hits 3.000.000 Milestone of Variable Frequency Drive (VFD)

Adrian Ellam, CEO of Invertek Drives Ltd, with Rhydian Welson, Sales and Marketing Director, and Glyn Jones, Technical Director (left to right)

Invertek Drives Ltd arrives this landmark just three years after the two-million milestone. These VFDs are used in applications across a broad spectrum of industries worldwide. These include manufacturing to optimise production line efficiency in processes like pumps, fans, and conveyors; HVAC building services to regulate ventilation, air conditioning, and water pumps in commercial and industrial buildings; water and wastewater to improve efficiency in water treatment plants and pumping stations; renewable energy to control wind turbines and solar tracking systems; to HVAC-R for optimising performance of heating, ventilation, air conditioning, and refrigeration systems.

Its Optidrive VFDs play a crucial role in reducing energy consumption of up to 50 per cent in some applications and associated emissions. By precisely controlling electric motors, they ensure they only use the power needed for the specific task, significantly reducing wasted energy. This technology is particularly impactful considering estimates suggest over 80 million electric motors operate globally without VFD control.

Designed and manufactured at the company's headquarters near Welshpool, UK, the production of the three millionth VFD represents Invertek Drives' ongoing commitment to innovation and sustainability.

“Tackling energy waste and emissions is a global priority," said Adrian Ellam, CEO of Invertek Drives Ltd. "Our VFDs provide a powerful and proven solution. Expanding their use will significantly impact environmental sustainability. We innovate relentlessly, ensuring our technology remains at the forefront of efficiency.”

www.invertekdrives.com

Read the full article

0 notes

Text

Achema 24: High-tech containment shroud for mag-drive pumps

One of the technical highlights at Achema 2024 will be the KSB's new 3D-printed containment shroud for mag-drive pumps of the Magnochem type series. Named MagnoProtect, the component offers the same safety as a double-walled containment shroud – without the latter’s disadvantages of heating up strongly and having high eddy current losses.

The new MagnoProtect offers the safety of a double-walled containment shroud without the latter’s disadvantages. ©KSB SE & Co. KGaA

According to manufacturer's information, “the overall efficiencies of the new mag-drive designs clearly exceed those of canned motor pumps”. Designed with a structure of channels, the new containment shroud offers a second, redundant, static safety barrier preventing leakage of the fluid handled.

A pressure transmitter monitors the vacuum generated, which is present during normal operation in the channels of the containment shroud. If the monitored pressure rises to atmospheric pressure, the outer containment shell is leaking. If the pressure rises above the ambient pressure, the inner containment shell is damaged. The containment shroud design is characterised by high mechanical strength and good wear properties. It has been optimised to minimise heat losses and eddy currents.

Converting a standardised chemical pump with mechanical seal to a magnetic drive is easier and more cost-efficient than retrofitting it with a canned motor. The geometry and dimensions of the new containment shroud are integrated in the modular system of Magnochem, allowing metallic or ceramic containment shrouds to be replaced easily. This enables operators to upgrade older pump sets that are still in service without difficulty.

www.ksb.com

Read the full article

0 notes

Text

Celebrating Sulzer`s 190 jubilee

Sulzer is a global player in fluid engineering. The company is specialized in pumping, agitation, mixing, separation and application technologies for fluids of all types.

www.sulzer.com

Read the full article

0 notes

Text

New retractable submerged pumps for small-scale LNG terminals and as emergency pumps or Cargo/Stripping pumps in the marine sector

Vanzetti Engineering is expanding its product portfolio by introducing a new family of submerged pumps, the ESK-IMO retractable series with flow rates from 70 m3/hr up to 500 m3/hr and a head of up to 240m. As the entire hydraulic and mechanical part derives from the well-known Artika Series.

The ESK-IMO Series is used in the industrial field in Small-scale terminals with a capacity of

Read the full article

0 notes

Text

New Food Waste Grinder to optimize Pumping Throughput

Focused on improving the waste-handling capabilities of the food industry, animal processing, and related waste-handling facilities, Vogelsang USA is bringing its largest format grinding system, the RedUnit XRL260.

Nicknamed “Big Red,” Vogelsang’s largest hopper-fed grinder to date is designed specifically to reduce large quantities of solid waste material quickly. The RedUnit XRL260 features two 50hp geared motors capable of handling up to 130 cubic yards of solid waste per hour (100 m3/h). The 5’ x 2’ inlet handles whole hogs and higher volumes of waste material. Existing installations have been able to increase throughput by 50-100% while reducing power consumption by as much as 50-60%.

Notable installations have been:

- Rendering plants: handling hogs, calves, and poultry – increased throughput by as much as 100%

- Biowaste, Process, and Post-Consumer: This includes organic waste, scraps, pits, and tops, as well as post-consumer waste with metal and plastic—50% energy savings compared to a hammermill.

- Slaughterhouse: bones innards, offal, skulls – lowered energy costs by 60%, increased protein output

- Pet Food: handled pallet-sized frozen blocks of animal waste – increased throughput by 100%, easy feeding improved operations.

Among the most notable features of the XRL260 is its side-entry maintenance design, specifically engineered to provide quick and safe access to the grinder's cutting elements. A “side flap” is easily opened to remove foreign objects, typically allowing one person to dismantle the one-piece cutting rotors. This ensures maximum uptime and quick, cost-effective maintenance.

Operational features:

- Lateral service hatches provide direct access to rotors to streamline maintenance and allow the easy removal of foreign bodies.

- Elimination of elaborate clearing systems

- Independent rotor direction and speed to adjust to any type of materials

Part of the new service concept from Vogelsang:

- Side panels easily lift up for removal of foreign bodies and maintenance.

- Direct access to rotors with maintenance that can be done by only one person if necessary.

- Ripper rotors can be easily removed for quick cleaning, ultimately extending the lifetime value of the machine

https://news.vogelsang.info/en/redunit-xrl-260

Read the full article

0 notes

Text

KSB provides insights into the 2023 financial year

Frankenthal-based (Germany) pump and valve manufacturer KSB closed the 2023 financial year with record figures for order intake and sales revenue. The EBIT margin (earnings before finance income / expense and income tax) of 7.9 % reached the level originally targeted for 2025.

In the 2023 financial year, KSB increased order intake by + 3.4 % to € 2,960 million. Order intake increased by 9.1 % to € 393 million in the Valves Segment and by 8.0 % to € 990 million in the KSB SupremeServ Segment. In the Pumps Segment, order intake of € 1,577 million stagnated almost at the previous year’s level.

KSB increased sales revenue by + 9.5 % to € 2,819 million in the 2023 financial year. Sales revenue rose by 11.0 % to € 944 million in the KSB SupremeServ Segment, while the Pumps Segment recorded an increase of 8.9 % to € + 1,514 million. The Valves Segment enjoyed a similar growth rate of 8.5 % to € 361 million.

The increase in the EBIT margin to 7.9 % was defined in particular by the growth in sales revenue and margin strength in the KSB SupremeServ Segment, which combines the business with spare parts and support services. KSB has significantly improved earnings before finance income / expense and income tax by 32.4 % to € 223.9 million. The KSB SupremeServ Segment made a significant contribution with growth of 22.7 % to € 179 million. EBIT in the Pumps Segment rose by 88.7 % to € 52 million. The Valves Segment posted EBIT of € – 7.5 million due to project provisions.

www.ksb.com

Read the full article

0 notes

Text

Europump announces additional Keynote Speaker for its 2024 Annual Meeting

Europump (the European Pump Association) which represents 15 National Associations across the continent of Europe continues to develop the programme of presentations for its 2024 Annual Meeting, taking place at the spectacular De Vere Beaumont Estate near Windsor from 22nd – 24th May.

In addition to sessions dedicated to the activities of the various Europump Commissions – Technical, Standards, Marketing, SME – a complement of invited speakers will also share their thoughts and expertise on a range of topical issues.

With the announcement in January of the first two guest speakers, namely, Stephen Phipson CBE, Chief Executive, Make UK, who will provide an overview of the political arena in the UK and its impact on the manufacturing sector both at home and abroad, and Kiran Ahmed, Lead Economist, Oxford Economics, who will present the key findings from the 2024 World Pump Report, the knowledge transfer bar had already been set extremely high. However, the team behind this residential conference is delighted to now

Mike Otten

also welcome Mike Otten, Director, Edge & Intelligence, Xylem as the third Keynote Speaker. Mike is part of the Corporate Growth & Innovation team at Xylem, where he focuses on digitizing water through AI, machine learning, and digital twins. He is committed to driving smart, disruptive change to improve business outcomes and fulfil Xylem’s purpose of making water more accessible, affordable, and communities more resilient.

With expertise in water technology, including holding a global patent in the field of digital wireless power transmission, Mike is passionate about solving problems associated with asset management and total system life cycle cost through digitalisation of assets and advanced data intelligence. Having worked and lived across Europe, the Middle East, Africa, and the US for global water technology OEMs and as a founder of two start-up businesses, he possesses deep insights into global business dynamics and cultural diversity. This specialised knowledge enables him to ease and accelerate the customer’s digital journey in optimising water assets and systems at scale.

Mike’s presentation, entitled ‘Unlocking the Power of AI: Elevating Pump Manufacturing Expertise’ will address the impact of Artificial Intelligence for the pump manufacturing industry, and how to harness the power of Digital Twins and Generative AI for an evolution of the sector. Specifically produced for the Europump Annual Meeting, this talk will detail how these technologies optimise asset performance, predict maintenance needs, and drive unprecedented efficiency gains within all types of pump systems.

Commenting on the inclusion of this highly relevant presentation, BPMA CEO, Wayne Rose, said: “We are thrilled to have secured the engagement of Mike Otten, a recognised expert in the field of digitisation, whose exploration of the transformative impact this technology has for business operations, cost reduction, and customer satisfaction, will be of real value to our audience. The insight given will allow attendees to better position their businesses at the forefront of innovation in the pump manufacturing industry.”

He continued: “The 2024 Europump Annual Meeting will prove to be a must-attend event for those senior pump executives looking to successfully navigate their way through the complexities of pump manufacturing and distribution over the coming months and years. As such, I would encourage anyone not already booked in to the event to do so straight away.”

www.Europump2024.com

Read the full article

0 notes

Text

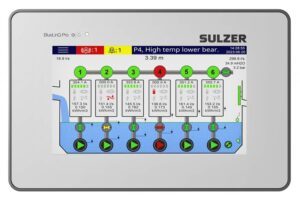

Sulzer launches next generation controller for optimized performance of wastewater pumping stations

Network pumping stations invariably encounter challenging conditions, and operators can face an uphill struggle to maintain reliability and low operating costs. BlueLinQ Pro, the latest addition to the Sulzer pump controller lineup, uses an intuitive, quick setup wizard for simplified configuration and uses experience-designed presets to solve complex operating scenarios.

Operators can interact seamlessly via the 7” touchscreen and use the integrated variable frequency drive (VFD) control to maximize pump efficiency and reduce energy costs. The new BlueLinQ Pro offers excellent scalability and is capable of controlling up to six assets including pumps, mixers and valves for the most effective operations.

Plug-and-play performance

The Sulzer BlueLinQ Pro offers advanced control features and a setup wizard that improve pump availability and reduce energy consumption - all within a small footprint that makes retrofitting easy. Built-in best efficiency point (BEP) and proportional integral derivative (PID) control logic functionality ensures that all pumps in the station operate as close to peak efficiency as possible. This reduces running costs and minimizes stress on the mechanical components.

Smart control functionality provides multiple features that optimize pump operations and minimize the need for interventions from the maintenance team. The ability to calculate in and outflows, measure the speed of level changes and vary pump start and stop points ensures each pumping station operates to its full potential. This includes the addition of mixers and valves, which can also be included in the control logic delivered by the BlueLinQ Pro.

Sulzer is setting a new standard for pumping station controllers. Simple module installation and configuration optimizes any retrofit by using multiple preset features to enhance performance. Round-the-clock remote monitoring and detailed analytics provide enhanced insights that support maintenance projects and minimize unnecessary call-outs.

Simplifying complex tasks

With so many very similar pumping stations in each network, the variety of controllers across sites can add unnecessary complexity for operators. The inherent flexibility of the BlueLinQ controller makes it ideal for many locations. Once the first station has been configured, all the settings can be easily transferred to others using the SD memory card facility, minimizing commissioning time.

To further enhance the benefits of the BlueLinQ Pro, modern communications protocols offer excellent connectivity and remote access possibilities to maximize the effectiveness of operators and technicians. Centralized monitoring and programing ensure valuable staff and resources are only dispatched when absolutely necessary.

In all, the features of this unique pump controller from Sulzer can support strategies to reduce operating costs, maximize reliability and optimize the productivity of the whole network.

www.sulzer.com

Ifat 24 Munich: Hall B1, Stand 321/420

Read the full article

0 notes

Text

New Video from Andritz Environment & Energy

New Video from Andritz Environment & Energy showing sustainable process technologies from water management, irrigation projects and desalination to waste-to-value solutions and clean air technologies through to the production of green hydrogen and renewable fuels.

Get more information

Read the full article

0 notes

Text

India’s giant lift irrigation project using some of the largest water pumps ever built with special shaft seals

Kaleshwaram Lift Irrigation Scheme

Canada’s Thordon Bearings is playing a vital role in providing water to arid regions, with the installation of axial shaft seals and filtration systems to the world’s largest irrigation project, in south central India. The Kaleshwaram Lift Irrigation Scheme (KLIS) in Telangana, India, has been constructed in a region characterized by water scarcity, aiming to efficiently utilise available water resources for agriculture.

As the world's largest multi-stage lift irrigation project, it runs for about 500 km (310 miles) through 13 districts and is connected to a 1770 km (1100 mile) canal network incorporating 20 reservoirs and extensive underground tunnels. It features some of the largest water pumps ever built.

SXL Axial shaft seal assemblies installed

A crucial component of the large pumps used in projects like this is the shaft seal, which prevents water leakage from lift pump shafts and flooding of the plant. The Francis-type inward-flow turbine pumps at Kaleshwaram work using a combination of radial and axial flow, requiring a reliable and robust seal design.

Thordon and its authorized distributor in India, Soneji Engineering Pvt. Ltd (SEPL), won a tender to supply 24 large diameter axial shaft seal assemblies, along with a water filtration system, for the project’s turbine pumps. The Thordon SXL Segmented Shaft Seal assembly was chosen for the project based on the product’s superior sealing capabilities, wear life, and extensive use across multiple markets.

“The agreement is for the supply of all components,” said Axel Swanson, Business Development Manager, Hydro & Industrial, Thordon Bearings. “This includes complete assembly, testing, installation, and commissioning on site.”

Thordon has designed the seal assembly and supplied its proprietary SXL material to SEPL, which was responsible for manufacturing all other components, as well as testing, installation, and commissioning on site. The work undertaken by SEPL was commissioned by Bharat Heavy Electrical Limited (BHEL).

www.thordonbearings.com

Read the full article

0 notes

Text

Revolutionizing food waste management: Seepex to host webinar on efficient handling of food waste and by-products

Seepex, a German provider of innovative pumping solutions, announces its upcoming webinar titled "Efficient Handling of Food Waste and By-Products." Two insightful sessions are scheduled for Thursday, March 21, 2024: one from 11 am to 12 pm (CET) and another from 3 pm to 4 pm (CET). This webinar aims to unveil groundbreaking techniques for managing food waste across various industries.

Food waste management presents a significant challenge for many sectors, from food processing plants to commercial kitchens. Recognising this challenge, Seepex has developed cutting-edge solutions to address it effectively. This webinar will showcase the company's advanced pumping systems, including macerators and grinders, designed specifically for the destruction of solids and the efficient handling of food waste.

Keynote speakers at the webinar include Damian Clifford, Commercial Leader at Seepex UK, and Peter Irwin, Northern Area Sales Manager.

Attendees can expect to learn about the the benefits of Seepex's food waste pumping technology:

- Replaces manual transfer between high-care and low-risk areas

- Enclosed pipework system ensures hygienic waste removal

- Up to 60% waste volume reduction

- Lower disposal costs

- Energy-efficient compared to traditional methods

- Pumps suitable for Clean-in-Place (CIP) or Sterilize-in-Place (SIP)

- Produces ideal feedstock for other applications

- Improved health and safety standards

"We are excited to host this webinar and share our expertise in efficient food waste management with industry professionals," says Damian.

To secure your spot and register for the webinar, please visit

Slot 1: 11 am – 12 pm (CET): Register now

Slot 2: 3 pm – 4 pm (CET): Register now

Read the full article

0 notes

Text

Seepex offers the webinar, "Pump Monitoring – Discover the Potential of Progressive Cavity Pumps” on March 13

On March 13, 2024, from 3 to 4 PM (CET) Philipp Janssen, Seepex's Global Product Manager for Digital Solutions, will unravel the intelligent monitoring concept, showcasing its application and benefits in a concise 60-minute session. The modular ecosystem promises a reduction in Total Cost of Ownership (TCO), optimizing pump operation and minimizing maintenance costs.

Register here

Read the full article

0 notes

Text

New Video: Grundfos shows SE/SL wastewater pumps

These pumps help you reduce energy consumption in wastewater applications by allowing to reduce the kW size of the pumps thanks to their high efficiency. The innovative Open S-tube impeller offers good operational reliability and saving money on maintenance.

www.grundfos.com

Read the full article

#clogging#Efficiency#energyconsuption#EnergySaving#energy-efficiency#Grundfos#submersible#Wastewater

0 notes

Text

Europump President Luboš Michlík Outlines Vision and Priorities for European Pump Industry

Luboš Michlík

Luboš Michlík became President of Europump, the European Pump Association, in June 2023 following his two-year tenure as Vice President. He has brought to the role a wealth of experience and a clear vision for the future of the European pump industry. As President, Michlík is committed to advancing Europump's mission of promoting excellence, innovation, and sustainability within the pump sector.

An experienced Engineer, specialising in sales and project management across the rotating machinery sector, Luboš has held various key positions with Czech Republic pump manufacturer, Sigma Group, best known for its mid-size, heavy and one-off specialised pumps and pumping sets for a wide range of industrial applications. He currently holds the position of CEO and Member of the Board of Directors, with responsibility for corporate structure, managing overall business operations, and setting the company's strategic direction.

As a representative of CPMA, (the Czech pump manufacturers association) Luboš has served Europump for many years. He became a Council Member in January 2019, and Chaired the strategic Blueprint Working Group before his election as First Vice-President in May 2021. He succeeds Vanni Vignoli, Chief Technical Officer at Wateralia and Council Member of Assopompe, Europump’s Italian association member, who held the position for the preceding two years.

Under Michlík's leadership, Europump is dedicated to enhancing collaboration between industry stakeholders and regulatory bodies to ensure the development and implementation of robust standards and directives. The association remains actively engaged in important initiatives related to various applicable directives, including the Eco-Design Directive, the Energy Labelling Directive, the Machinery Directive, and the Drinking Water Directive, each of which will have a significant impact on the pump sector.

Another key topic of interest for both the Technical and Standards Commissions within Europump is the restriction in use of PFAS materials (per- and polyfluoroalkyl substances). Given their presence in a wide variety of products associated with pump installations, such as sealings, bearings, cable sheaths, coatings, pump inserts and membranes, any restriction must be fully considered, and possible alternatives identified, before any changes come into force.

"As President of Europump, my primary focus is to champion the interests of the European pump industry and drive positive change that benefits both our members and society as a whole," says Luboš Michlík. "We are committed to upholding the highest standards of quality, safety, and environmental responsibility across all aspects of our industry."

As Europump continues its complex work under Michlík's leadership, assisted by the Chairs and members of the various commissions – Standards, Technical, Marketing and SME - the association remains steadfast in its dedication to advancing the interests and priorities of the European pump industry, while promoting sustainability, innovation, and excellence across all aspects of its work.

www.europump.net

Read the full article

0 notes

Text

New Pump Handbook from Alfa Laval

The 375-page handbook is free and contains scholarly information on basic pump functionality and in-depth guidelines for sizing and selecting the right pump type for optimum efficiency. The handbook is packed with real-life examples to increase its user-friendliness.

The first edition of the Alfa Laval Pump Handbook was published 25 years ago and soon became part of the syllabus at engineering schools around the world. The book also found its way into manufacturing sites, serving as a reference work to technicians in the daily operation of fluid handling processes.

Over the years, the handbook has gone through minor revisions, and in 2023, a major overhaul was undertaken to make the handbook up-to-date on the most recent technologies.

“We have worked hard to provide the global pump community with the most recent knowledge about pump functionality and leading-edge technologies that enhance pump efficiency to meet the sustainability agenda of societies and industries. Pumps are among the most power consuming devices in fluid handling processes, and the potential for energy savings is big, when you select the right pump from the start and maintain it along the way,” says Lars Sørensen, Manager, Product Management at Alfa Laval .

The authors of the book are experienced pump engineers with extensive theoretical knowledge and hands-on experience from pump installations and training of technical staff in fluid handling industries.

Available online

The handbook is free and available online. It can be downloaded from www.alfalaval/PumpHandbook and contains a series of videos on for instance pump functionality, troubleshooting and maintenance guidelines.

The main chapters of the handbook comprise:

- Basic theory on pumping applications

- Pump types for different applications

- Pump sizing for maximum efficiency

- Pump specification

- Pump motors

- Troubleshooting

- Technical data and formulas

www.alfalaval.com

Read the full article

0 notes